Understanding Twin Screw Compounders: Enhancing Plastic Processing Efficiency

2025-12

One of the key advantages of twin screw compounders is their ability to provide a high level of mixing and dispersion of additives, fillers, and reinforcements within the polymer matrix. This is crucial for producing high-quality end products with consistent properties. The intermeshing screw design ensures that materials are subjected to both shear and elongational forces, which enhances the homogeneity of the mixture and facilitates efficient heat transfer. Additionally, the modular design of twin screw compounders allows for the integration of various processing functions, such as vacuum devolatilization, melt pumping, and pelletizing.

The versatility of twin screw compounders makes them suitable for a wide range of applications. Industries such as automotive, electronics, and packaging often utilize these machines to compound engineering plastics, thermoplastics, and specialty materials. With the increasing demand for high-performance materials, twin screw compounders are becoming increasingly important in developing advanced composites that can meet stringent performance standards.

In terms of operation, twin screw compounders are equipped with advanced control systems that allow for precise monitoring and adjustment of processing parameters. This level of control is vital for optimizing the quality and consistency of the output, as well as for minimizing waste during production. Furthermore, the ability to incorporate real-time feedback into the processing cycle enables manufacturers to respond quickly to changes in material characteristics, ensuring a more efficient production process.

When considering a twin screw compounder for your production line, it is essential to evaluate factors such as throughput, screw design, and the specific requirements of your materials. Understanding the operational dynamics of twin screw compounders will enable manufacturers to make informed decisions that enhance productivity and product quality.

In conclusion, twin screw compounders play a pivotal role in modern plastic processing, offering superior mixing, enhanced material properties, and operational efficiency. As the demand for innovative and high-performance materials continues to rise, the significance of twin screw compounders in achieving these goals cannot be overstated. By leveraging the capabilities of these machines, manufacturers can stay at the forefront of the plastic processing industry.

Previous Page:

RELATED INFORMATION

Understanding Twin Screw Compounders: Enhancing Plastic Processing Efficiency

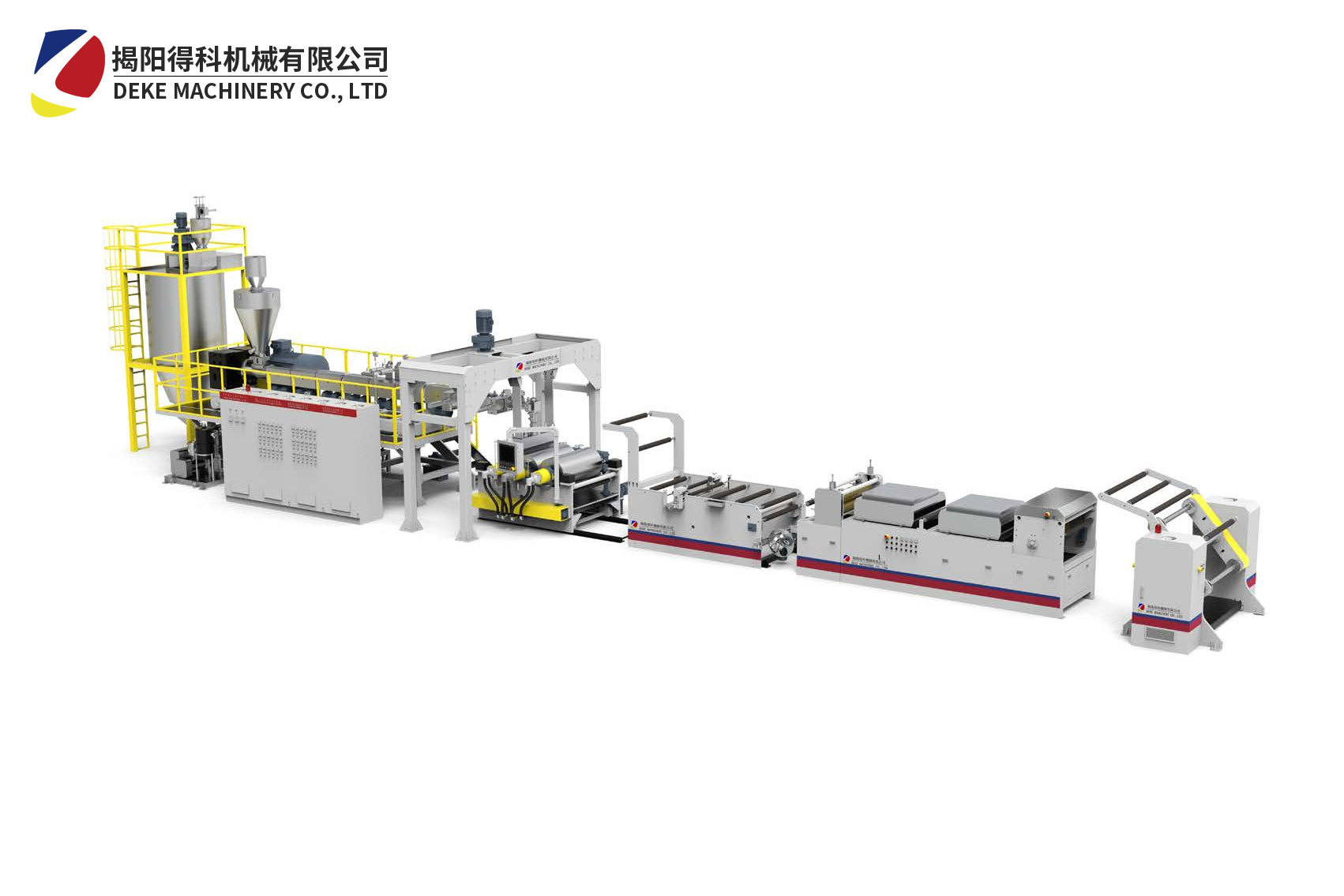

Twin screw compounders are essential machines in the plastic processing industry, particularly in the manufacturing of polymers and composites. These sophisticated devices are designed to melt, mix, and compound plastic materials efficiently. Their unique configuration, featuring two intermeshing screws, allows for improved material handling and processing capabilities compared to single screw ext

How PET Sheet Extruders Revolutionize Plastic Processing Machinery

How PET Sheet Extruders Revolutionize Plastic Processing Machinery Table of Contents Introduction to PET Sheet Extruders Understanding Plastic Processing Machinery The Technology Behind PET Sheet Extruders Advantages of Using PET Sheet Extruders Sustainability in Plastic Manufacturing Applications of PET Sheets in Various Industries Future Trends in PET Sheet Extrusion