2026/01

Why Choose Conical Twin Screw for Your Next Extrusion Project?

Why Choose Conical Twin Screw for Your Next Extrusion Project? Understanding Extrusion Technology In the realm of **plastic processing**, extrusion is an essential manufacturing technique that transforms raw plastic materials into usable products. The **extrusion process** involves forcing molten plastic through a die to create continuous shapes like sheets, films, and profiles. With advancements

2026/01

Understanding the Advantages of Counter Rotating Twin Screw Extruders for Plastic Processing

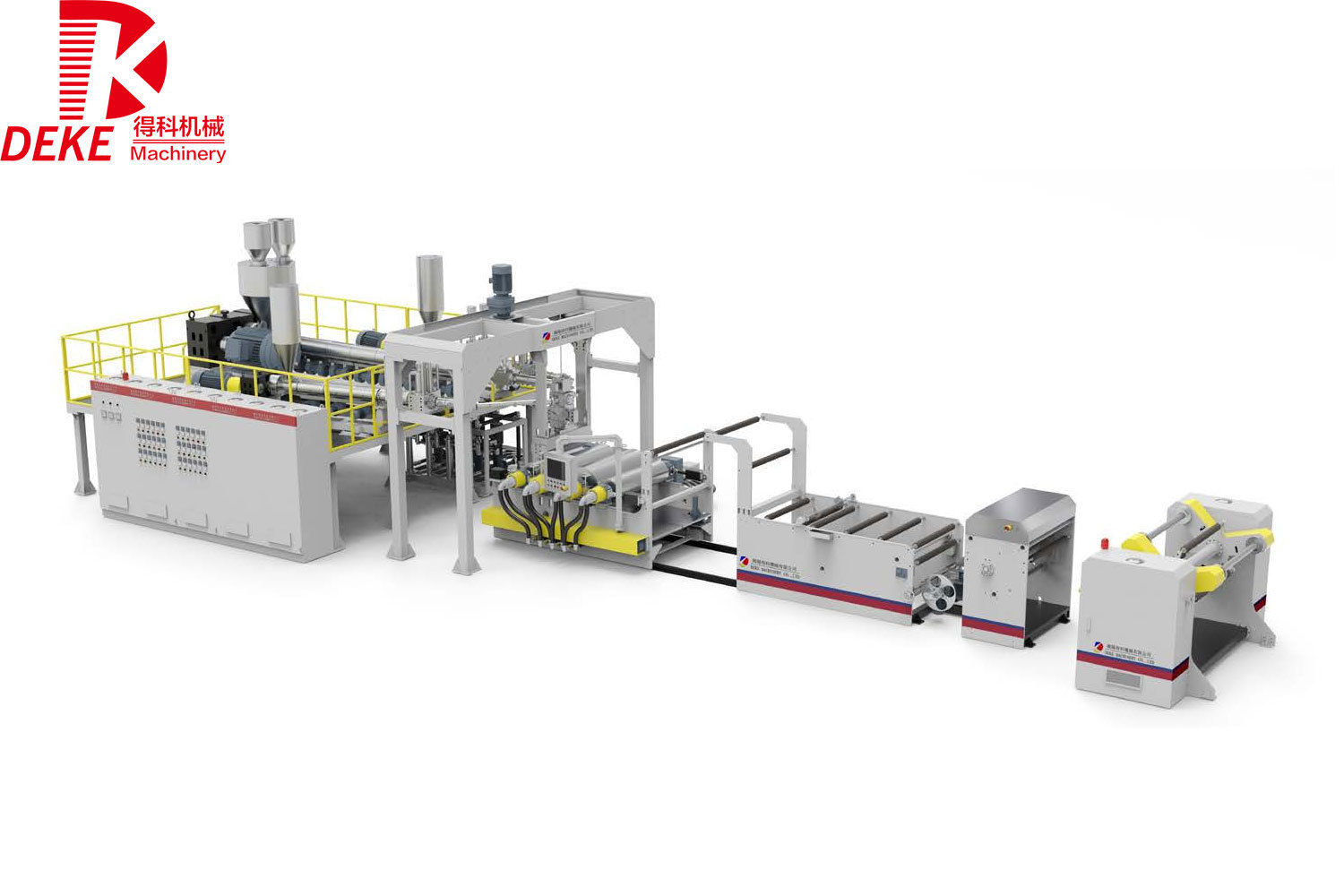

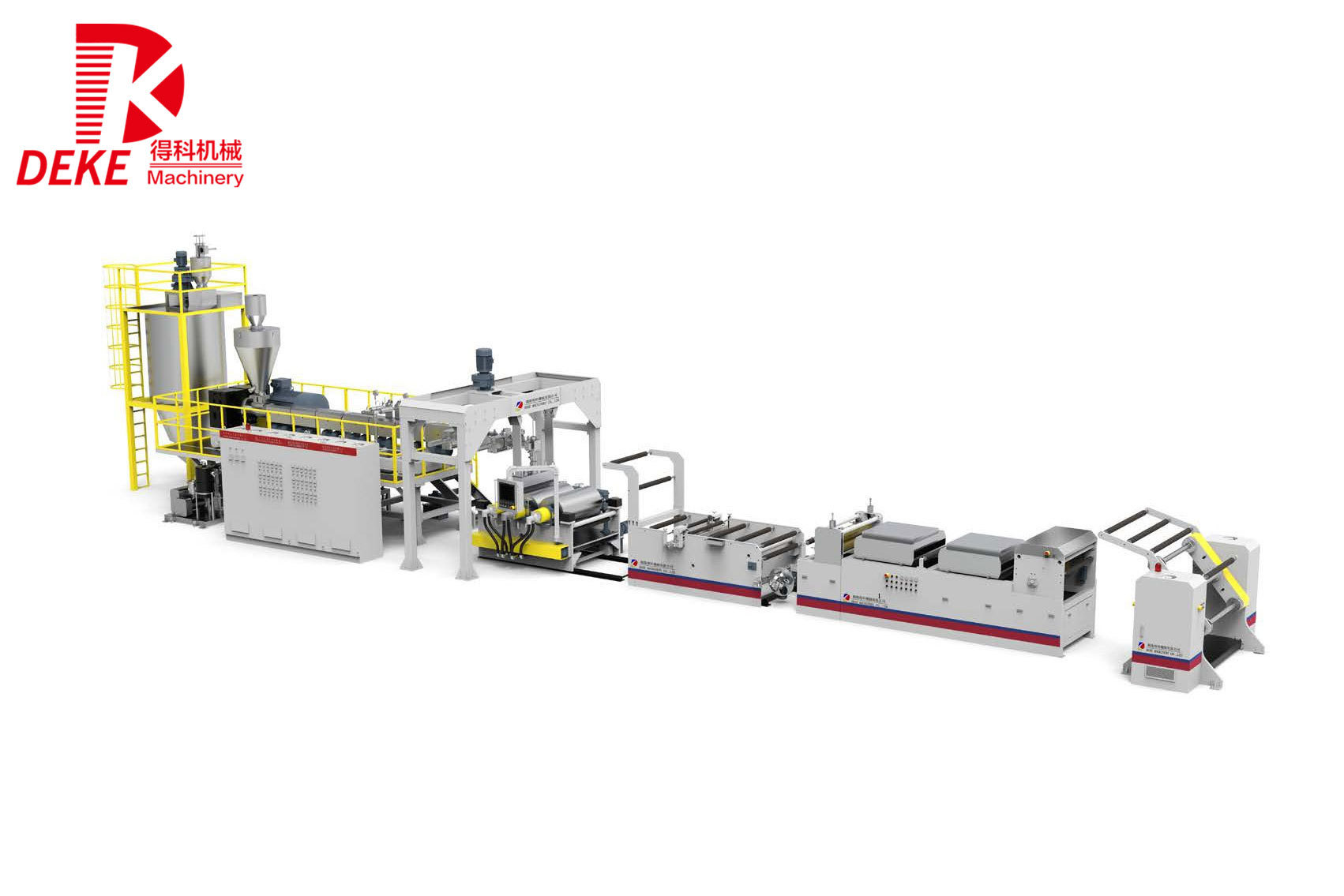

Counter rotating twin screw extruders are pivotal in the plastic processing industry, recognized for their versatility and efficiency. Unlike single screw extruders, twin screw extruders feature two intermeshing screws that rotate in opposite directions. This design allows for enhanced material handling and processing capabilities, making them suitable for a wide array of applications. One of the

2026/01

Understanding the Mechanisms of Twin Screw Compounders in Polymer Processing

Understanding the Mechanisms of Twin Screw Compounders in Polymer Processing Polymer processing serves as a cornerstone for numerous industries, from packaging to automotive. Among various processing techniques, **twin screw compounding** has emerged as a critical technology for achieving high efficiency and adaptability. This article will explore the mechanisms of twin screw compounders, their op

2026/01

Understanding the Benefits and Applications of Small Twin Screw Extruders

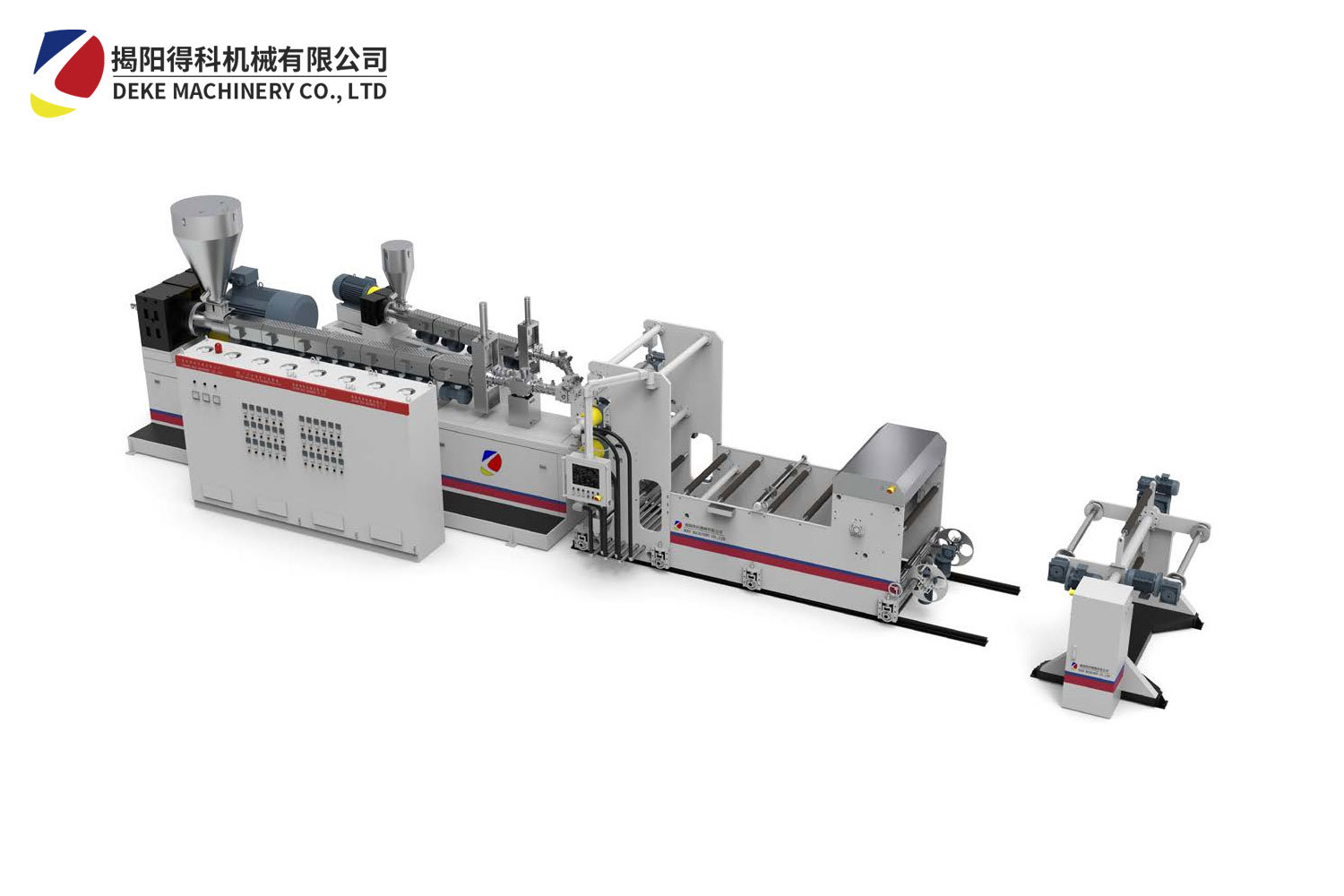

Small twin screw extruders are a pivotal innovation in the realm of plastic processing machinery, specifically designed to enhance the efficiency and versatility of manufacturing processes. Unlike their single-screw counterparts, these machines feature two intermeshing screws that work in tandem to convey and process materials with greater precision. This unique design enables small twin screw ext

2026/01

Maximizing Energy Efficiency in Your PET Extrusion Sheet Line: A Comprehensive Guide

Maximizing Energy Efficiency in Your PET Extrusion Sheet Line: A Comprehensive Guide Table of Contents 1. Introduction 2. Understanding Energy Efficiency in PET Extrusion 3. Key Factors Affecting Energy Consumption in PET Extrusion 4. Strategies for Enhancing Energy Efficiency 4.1 Optimizing Extruder Design 4.2 Utilizing Advanced

2026/01

Understanding the Advantages and Applications of PET Single Screw Extruders

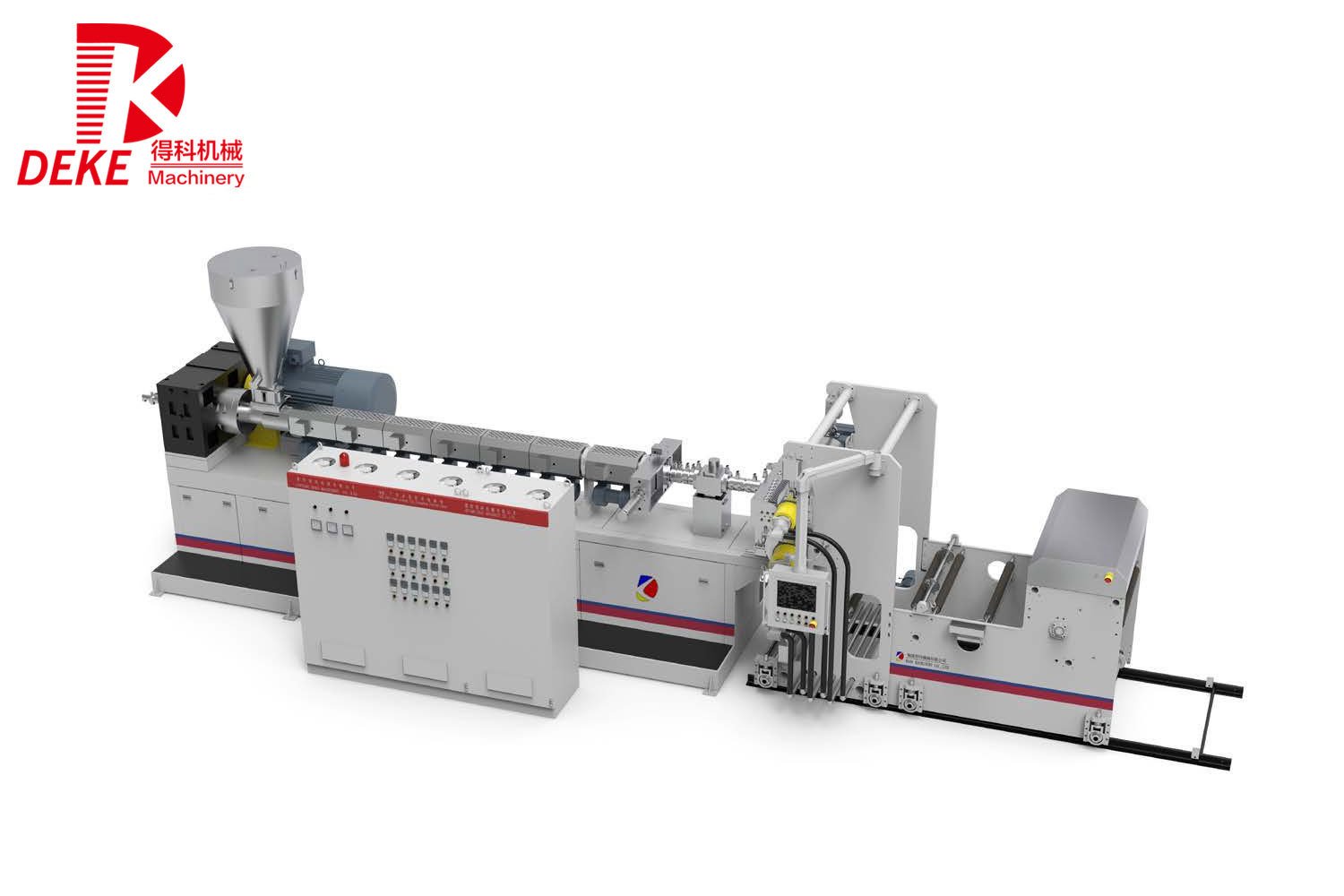

PET (Polyethylene Terephthalate) single screw extruders are essential equipment in the plastic processing industry, particularly for applications involving the production of PET products. These extruders are designed to efficiently convert PET pellets into a continuous flow of plastic material, making them an integral part of the manufacturing process in various sectors, including packaging, texti

2026/01

Why Choose a PET Sheet Extruder for Your Plastic Manufacturing Needs?

Why Choose a PET Sheet Extruder for Your Plastic Manufacturing Needs? In the ever-evolving landscape of plastic manufacturing, the choice of machinery plays a critical role in determining product quality, production efficiency, and overall business success. Among the myriad of options available, the PET (Polyethylene Terephthalate) sheet extruder stands out as a superior choice for manufacturers a

2026/01

Unleashing the Power of PET Twin Screw Extruders in Plastic Manufacturing

In the realm of plastic processing machinery, PET twin screw extruders stand out as a robust solution for various applications, particularly in the production of polyethylene terephthalate (PET) materials. These extruders operate using two intermeshing screws that enhance the mixing and melting of plastics, resulting in superior product quality and operational efficiency. One of the key advantages

2026/01

The Essential Role of Conical Twin Screws in Optimizing Plastic Manufacturing Processes

The Essential Role of Conical Twin Screws in Optimizing Plastic Manufacturing Processes Table of Contents Introduction to Conical Twin Screws in Plastic Manufacturing What Are Conical Twin Screws? Advantages of Conical Twin Screws in Plastic Processing Mechanism of Action of Conical Twin Screws Applications of Conical Twin Screws in Plastic Manufacturing Impact on Product

2026/01

Twin Screw Compounders: The Key to Sustainable Plastic Manufacturing

Twin Screw Compounders: The Key to Sustainable Plastic Manufacturing Introduction to Twin Screw Compounders In the ever-evolving world of plastic manufacturing, **twin screw compounders** have emerged as a pivotal technology that significantly enhances production efficiency and sustainability. These advanced machines allow manufacturers to combine diverse materials into uniform compounds, crucial

RELATED INFORMATION

Why Choose Conical Twin Screw for Your Next Extrusion Project?

Why Choose Conical Twin Screw for Your Next Extrusion Project? Understanding Extrusion Technology In the realm of **plastic processing**, extrusion is an essential manufacturing technique that transforms raw plastic materials into usable products. The **extrusion process** involves forcing molten plastic through a die to create continuous shapes like sheets, films, and profiles. With advancements

Understanding the Advantages of Counter Rotating Twin Screw Extruders for Plastic Processing

Counter rotating twin screw extruders are pivotal in the plastic processing industry, recognized for their versatility and efficiency. Unlike single screw extruders, twin screw extruders feature two intermeshing screws that rotate in opposite directions. This design allows for enhanced material handling and processing capabilities, making them suitable for a wide array of applications. One of the