Understanding the Advantages and Applications of PET Single Screw Extruders

2026-01

One of the primary advantages of using PET single screw extruders is their ability to handle the unique thermal and viscosity characteristics of PET. This material has a high melting point and can degrade if not processed correctly. A single screw extruder is specifically designed to maintain precise temperature control throughout the extrusion process, ensuring that the PET is melted uniformly without degradation. This is crucial for producing high-quality end products with optimal properties.

The single screw design allows for a more straightforward and effective mixing of additives and colorants during the extrusion process. This is particularly beneficial when manufacturing products that require specific color or functional properties, as it allows for a consistent distribution of materials. Furthermore, the design is generally easier to maintain and operate compared to twin screw extruders, making it a popular choice for many manufacturers.

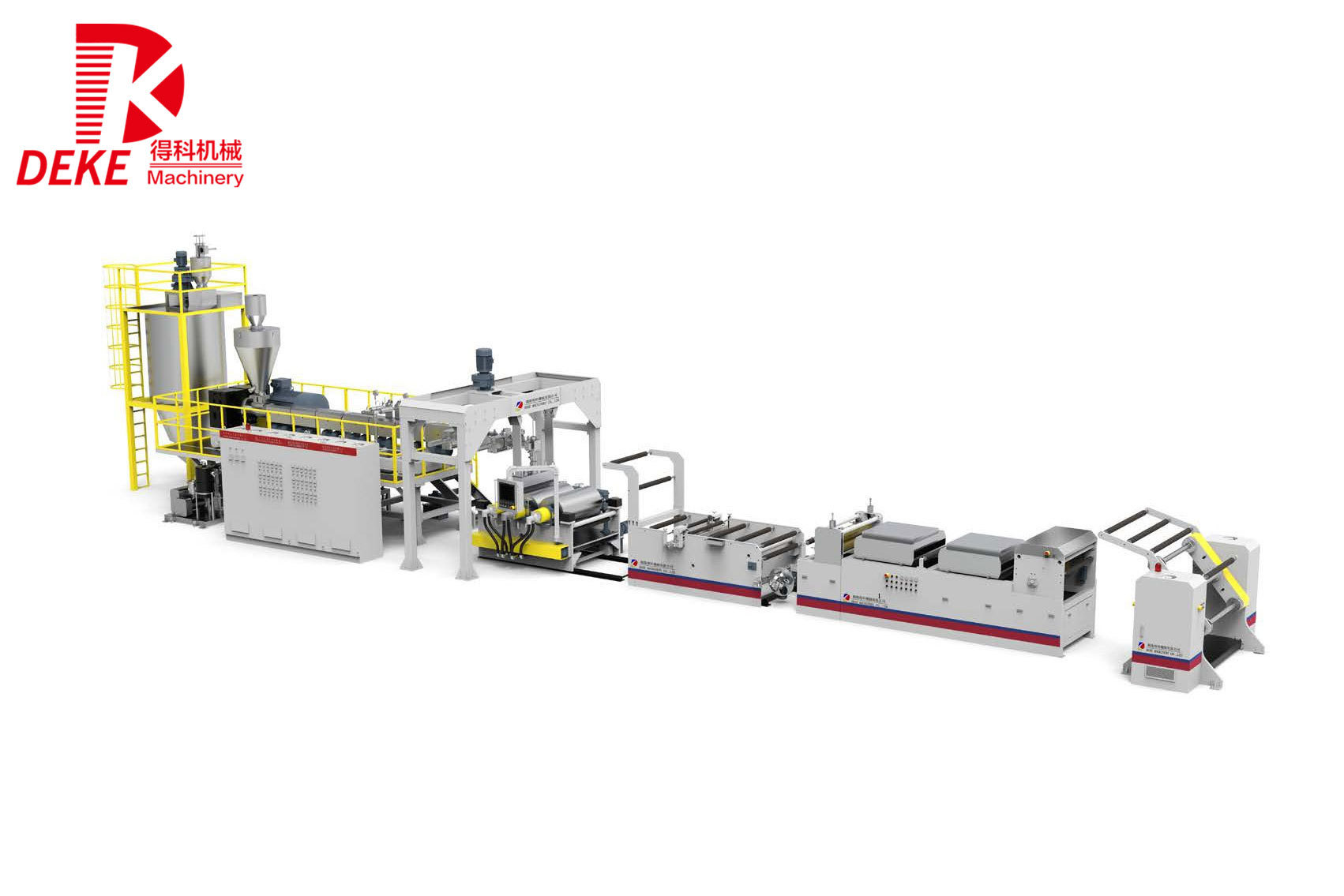

In terms of applications, PET single screw extruders are widely used in producing various plastic products, including bottles, films, and sheets. The versatility of PET makes it suitable for high-performance applications, where strength, clarity, and thermal resistance are essential. For instance, in the food packaging industry, PET's barrier properties help preserve freshness and extend shelf life, making it a preferred choice for manufacturers.

Moreover, advancements in technology have led to the development of specialized screw designs and processing techniques that enhance the performance of PET single screw extruders. Features such as adjustable feed sections, cooling systems, and improved barrel designs contribute to greater efficiency and energy savings during operation. This not only improves the overall productivity of the manufacturing process but also reduces the environmental footprint.

In summary, PET single screw extruders are a vital part of the plastic processing machinery landscape, offering numerous advantages for manufacturers. Their ability to handle the specific requirements of PET, combined with their versatility in applications, makes them an indispensable tool in producing high-quality plastic products. As the demand for PET continues to rise, understanding the benefits and capabilities of single screw extruders will remain crucial for businesses looking to optimize their production processes.

Previous Page:

RELATED INFORMATION

Understanding the Advantages and Applications of PET Single Screw Extruders

PET (Polyethylene Terephthalate) single screw extruders are essential equipment in the plastic processing industry, particularly for applications involving the production of PET products. These extruders are designed to efficiently convert PET pellets into a continuous flow of plastic material, making them an integral part of the manufacturing process in various sectors, including packaging, texti

Why Choose a PET Sheet Extruder for Your Plastic Manufacturing Needs?

Why Choose a PET Sheet Extruder for Your Plastic Manufacturing Needs? In the ever-evolving landscape of plastic manufacturing, the choice of machinery plays a critical role in determining product quality, production efficiency, and overall business success. Among the myriad of options available, the PET (Polyethylene Terephthalate) sheet extruder stands out as a superior choice for manufacturers a