Why Choose a PET Sheet Extruder for Your Plastic Manufacturing Needs?

2026-01

Why Choose a PET Sheet Extruder for Your Plastic Manufacturing Needs?

In the ever-evolving landscape of plastic manufacturing, the choice of machinery plays a critical role in determining product quality, production efficiency, and overall business success. Among the myriad of options available, the PET (Polyethylene Terephthalate) sheet extruder stands out as a superior choice for manufacturers aiming to achieve excellence in both performance and sustainability. This article delves into the reasons why selecting a PET sheet extruder can be a game-changer for your plastic manufacturing needs.

Understanding PET and Its Applications in Manufacturing

PET is a thermoplastic polymer widely recognized for its strength, durability, and versatility. It is primarily used in the production of bottles, containers, films, and sheets. The exceptional characteristics of PET make it an ideal material for numerous applications, including:

- Food and beverage packaging

- Medical supplies and equipment

- Textiles and fibers

- Industrial applications

The use of PET in these applications is largely driven by its favorable properties, such as chemical resistance, lightweight, and excellent barrier performance against moisture and gases. Therefore, investing in a PET sheet extruder translates into aligning your production with the demands of various industries.

Key Benefits of Using a PET Sheet Extruder

1. Enhanced Production Efficiency

One of the primary advantages of a PET sheet extruder is its ability to significantly enhance production efficiency. These machines are designed to operate at high speeds, allowing manufacturers to produce large quantities of sheets in a shorter time frame. Moreover, the advanced technology employed in modern PET extruders minimizes downtime and maintenance requirements, ensuring a smoother production process.

2. Superior Product Quality

High-quality output is non-negotiable in the competitive world of plastic manufacturing. PET sheet extruders are engineered to deliver consistent thickness, clarity, and surface finish, which are crucial for meeting industry standards. The precision of these machines ensures that manufacturers can produce sheets that not only meet but exceed customer expectations.

3. Versatility in Production

PET sheet extruders offer remarkable versatility, enabling manufacturers to produce a wide range of products. From rigid sheets used in packaging to flexible films employed in various applications, the adaptability of PET allows for customization based on specific market demands. This flexibility is essential for manufacturers looking to diversify their product offerings.

4. Environmentally Friendly Option

With increasing awareness of environmental issues, the sustainability aspect of manufacturing is more important than ever. PET is a recyclable material, and utilizing a PET sheet extruder supports eco-friendly practices in production. Many manufacturers are turning to these machines to optimize their sustainable production processes while still meeting high-quality standards.

5. Cost-Effectiveness Over Time

While the initial investment in a PET sheet extruder might be higher than other machines, the long-term cost benefits are significant. The durability and efficiency of PET extruders lead to reduced operational costs, lower waste generation, and improved energy efficiency. This translates to a better return on investment for manufacturers.

Key Features of PET Sheet Extruders

1. Advanced Control Systems

Modern PET sheet extruders are equipped with state-of-the-art control systems that provide operators with real-time data and analytics. This technology enables precise adjustments during the production process, ensuring optimal performance and product quality.

2. Multi-Layer Extrusion Capabilities

Some PET sheet extruders come with multi-layer extrusion technology, allowing manufacturers to create sheets with varying properties. This capability is particularly beneficial for producing specialized products that require specific barriers or finishes.

3. Customizable Die Designs

Die design is critical in determining the final product characteristics. Many PET sheet extruders offer customizable die options, enabling manufacturers to tailor their sheets for enhanced performance and aesthetics. This flexibility can be a decisive factor in staying competitive in the market.

4. Energy Efficiency Features

Energy consumption is a significant concern in manufacturing. Today's PET sheet extruders are designed to operate with minimal energy usage, incorporating features such as efficient heating systems and insulation to reduce operational costs and environmental impact.

5. User-Friendly Interfaces

Ease of operation is crucial for maximizing productivity. Modern PET sheet extruders often come with user-friendly interfaces that simplify the setup and monitoring of production processes. This ease of use can lead to shorter training times and improved overall efficiency.

Choosing the Right PET Sheet Extruder for Your Needs

1. Assess Your Production Requirements

Before investing in a PET sheet extruder, it is essential to assess your specific production requirements, including expected output volume, sheet dimensions, and desired product characteristics. Understanding these needs will help you select a machine that aligns with your operational goals.

2. Evaluate Machine Specifications

Consider the specifications of various models, including their production capacity, energy efficiency ratings, and any additional features that may enhance your production process. Analyzing these specifications in detail will help you make an informed decision.

3. Seek Expert Consultation

Consulting with industry experts or manufacturers can provide valuable insights into the best PET sheet extruders available in the market. These professionals can help you navigate the options and select a machine that fits your unique requirements.

4. Consider After-Sales Support

After-sales support is a crucial factor when choosing a PET sheet extruder. Ensure that the manufacturer provides adequate training, maintenance services, and technical support to help you get the most out of your investment.

Common FAQs About PET Sheet Extruders

1. What is a PET sheet extruder?

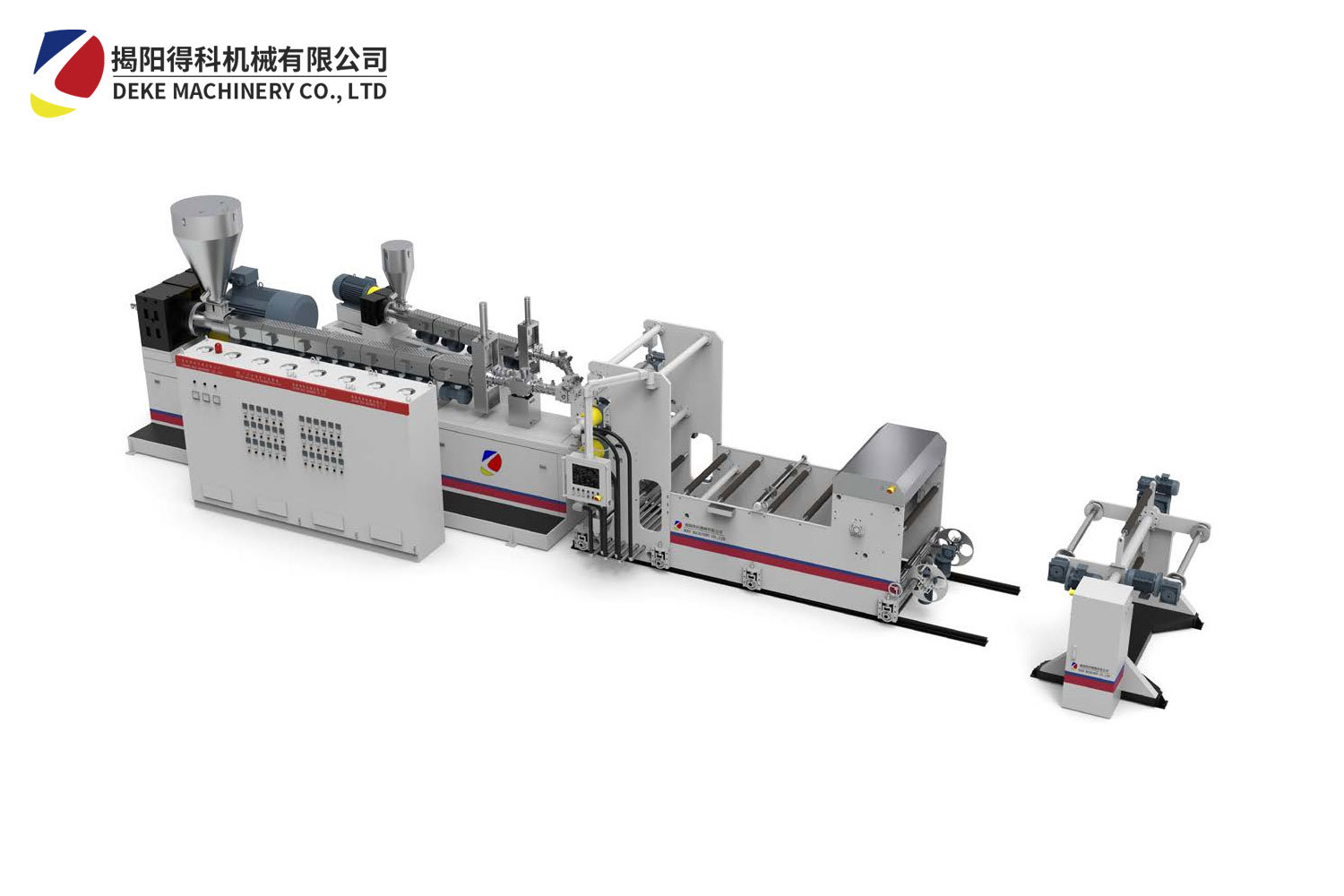

A PET sheet extruder is a machine used to manufacture PET sheets by melting and shaping the polymer into flat sheets through a die. These extruders are known for their efficiency and ability to produce high-quality sheets for various applications.

2. What are the advantages of PET sheets?

PET sheets offer numerous advantages, including excellent strength, chemical resistance, clarity, and recyclability. They are widely used in packaging, industrial applications, and consumer products.

3. How does a PET sheet extruder work?

The process begins with feeding PET pellets into the extruder, where they are melted and conveyed through heated zones. The molten polymer is then shaped into sheets as it passes through a die, followed by cooling and cutting to desired dimensions.

4. Can PET sheet extruders produce multi-layer sheets?

Yes, many modern PET sheet extruders have multi-layer extrusion capabilities, allowing for the production of sheets with varying properties, such as barriers to moisture or specific surface finishes.

5. Are PET sheets environmentally friendly?

Yes, PET sheets are recyclable, making them an environmentally friendly option compared to other plastics. Utilizing PET in manufacturing can contribute to sustainable production practices.

Conclusion

Choosing a PET sheet extruder for your plastic manufacturing needs is a strategic decision that can lead to enhanced efficiency, superior product quality, and sustainable practices. By understanding the key benefits, features, and considerations involved in selecting a PET sheet extruder, you position your business for success in a competitive marketplace. With the right extruder, manufacturers can not only meet current market demands but also adapt to future challenges, ensuring long-term growth and sustainability in the plastic manufacturing industry.

Previous Page:

RELATED INFORMATION

Why Choose a PET Sheet Extruder for Your Plastic Manufacturing Needs?

Why Choose a PET Sheet Extruder for Your Plastic Manufacturing Needs? In the ever-evolving landscape of plastic manufacturing, the choice of machinery plays a critical role in determining product quality, production efficiency, and overall business success. Among the myriad of options available, the PET (Polyethylene Terephthalate) sheet extruder stands out as a superior choice for manufacturers a

Unleashing the Power of PET Twin Screw Extruders in Plastic Manufacturing

In the realm of plastic processing machinery, PET twin screw extruders stand out as a robust solution for various applications, particularly in the production of polyethylene terephthalate (PET) materials. These extruders operate using two intermeshing screws that enhance the mixing and melting of plastics, resulting in superior product quality and operational efficiency. One of the key advantages