Why Choose Conical Twin Screw for Your Next Extrusion Project?

2026-01

Why Choose Conical Twin Screw for Your Next Extrusion Project?

Understanding Extrusion Technology

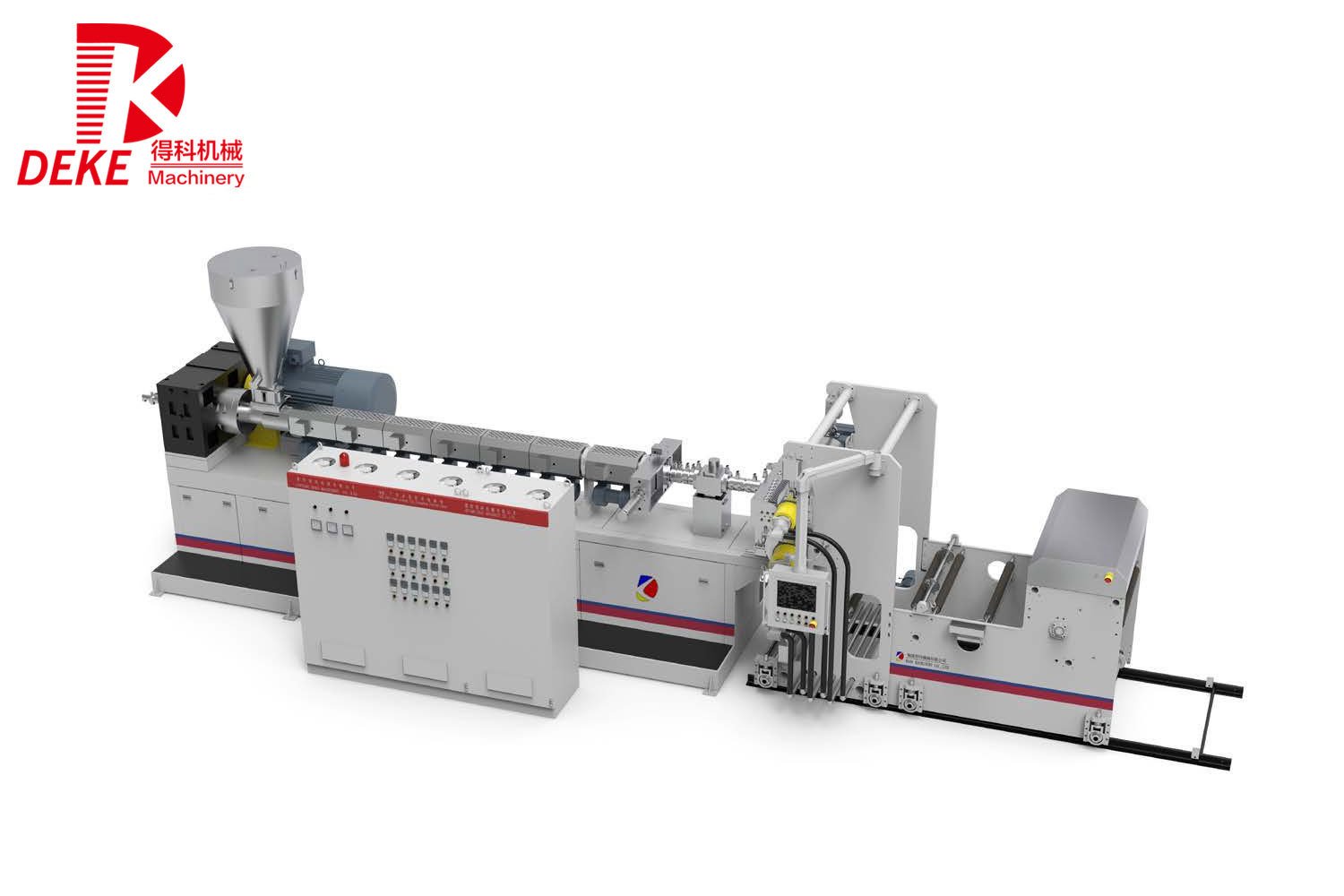

In the realm of **plastic processing**, extrusion is an essential manufacturing technique that transforms raw plastic materials into usable products. The **extrusion process** involves forcing molten plastic through a die to create continuous shapes like sheets, films, and profiles. With advancements in technology, the development of the conical twin screw extruder has revolutionized this process, providing manufacturers with enhanced capabilities and efficiency.

The Mechanics Behind Conical Twin Screw Extruders

Conical twin screw extruders employ two intermeshing screws that rotate in opposite directions. This unique design is characterized by its conical geometry, where the diameter of the screws decreases from the feed section to the discharge section. This **conical design** optimizes the flow of material, ensuring uniform melting and mixing.

Key Features of Conical Twin Screw Extruders

1. **High Mixing Efficiency**: The intermeshing configuration allows for superior mixing of materials, resulting in homogenous blends essential for producing high-quality plastic products.

2. **Versatility**: Suitable for processing a variety of materials, including **thermoplastics**, **thermosets**, and even **bio-based plastics**, making it ideal for diverse applications.

3. **Enhanced Control**: The ability to finely control temperature profiles, pressure, and feed rates allows for greater precision in the extrusion process.

Advantages of Choosing Conical Twin Screw Extruders

When selecting an extruder for your project, the decision to choose a conical twin screw model can significantly impact your production efficiency and product quality. Below are some of the most compelling reasons to consider this option:

1. Improved Material Processing

Conical twin screw extruders are designed to handle difficult-to-process materials. Their ability to provide consistent shear rates and mixing conditions ensures optimal melting and material flow, minimizing degradation and maximizing output quality.

2. Increased Output and Productivity

With their efficient design, conical twin screw extruders can achieve higher output rates compared to single screw extruders. The enhanced mixing capabilities lead to faster processing times, allowing companies to meet higher production demands without compromising quality.

3. Energy Efficiency

Energy consumption is a critical concern in manufacturing. Conical twin screw extruders are known for their energy-efficient operation. By optimizing the melting and mixing processes, these machines reduce energy costs while maintaining high performance.

4. Flexibility in Application

The versatility of conical twin screw extruders makes them suitable for a wide range of applications, from producing plastic compounds and masterbatches to food processing and pharmaceuticals. This flexibility enables manufacturers to adapt to changing market demands without the need for extensive equipment modifications.

Examples of Applications

- **Plastic Compounding**: Mixing various plastic resins with additives to enhance specific properties.

- **Film and Sheet Extrusion**: Producing high-quality films and sheets for packaging and other applications.

- **Recycling Processes**: Processing post-consumer plastics into reusable materials.

Factors to Consider When Selecting a Conical Twin Screw Extruder

Choosing the right conical twin screw extruder for your project requires careful consideration of several factors:

1. Material Compatibility

Not all extruders are suitable for every type of material. Ensure the chosen extruder can handle the specific polymers you plan to process, including their viscosity and thermal properties.

2. Production Volume

Assess your production needs. Larger projects may require high-capacity extruders, while smaller operations might benefit from more compact models.

3. Budget and Cost Efficiency

Analyze the total cost of ownership, considering not just the initial purchase price, but also operating costs, maintenance, and potential energy savings.

Maintenance and Care for Conical Twin Screw Extruders

To maximize the lifespan and performance of your conical twin screw extruder, regular maintenance is essential.

1. Routine Inspections

Conduct routine inspections to identify wear and tear on screws and barrels. Early detection can prevent costly repairs and downtime.

2. Cleaning Procedures

Implement proper cleaning procedures to prevent material contamination between batches. This is especially crucial when switching from one polymer type to another.

Frequently Asked Questions (FAQs)

1. What is the main advantage of using a conical twin screw extruder over a single screw extruder?

The primary advantage lies in superior mixing and melting efficiency, which results in higher quality products and reduced processing times.

2. Can conical twin screw extruders handle recycled materials?

Yes, these extruders are well-suited for processing a variety of materials, including recycled plastics, making them an excellent choice for sustainable manufacturing.

3. How do I determine the right size of a conical twin screw extruder for my application?

Consider your production volume and the specific materials you will process. Consulting with manufacturers can help you select the appropriate model.

4. Are conical twin screw extruders energy-efficient?

Yes, their design allows for optimized melting and mixing, which can lead to significant energy savings during operation.

5. What maintenance is required for conical twin screw extruders?

Routine inspections, proper cleaning procedures, and timely replacement of worn components are crucial for maintaining performance and longevity.

Conclusion

In summary, **conical twin screw extruders** present a multitude of advantages for manufacturers engaged in plastic processing. Their ability to provide enhanced mixing, improve output quality, and ensure energy efficiency makes them a preferred choice for various applications. By investing in a conical twin screw extruder for your next extrusion project, you not only enhance your production capabilities but also position your business for future growth and adaptability in a competitive market. Make the decision today to leverage the benefits of this advanced technology and drive your manufacturing success.

Previous Page:

RELATED INFORMATION

Why Choose Conical Twin Screw for Your Next Extrusion Project?

Why Choose Conical Twin Screw for Your Next Extrusion Project? Understanding Extrusion Technology In the realm of **plastic processing**, extrusion is an essential manufacturing technique that transforms raw plastic materials into usable products. The **extrusion process** involves forcing molten plastic through a die to create continuous shapes like sheets, films, and profiles. With advancements

Understanding the Advantages of Counter Rotating Twin Screw Extruders for Plastic Processing

Counter rotating twin screw extruders are pivotal in the plastic processing industry, recognized for their versatility and efficiency. Unlike single screw extruders, twin screw extruders feature two intermeshing screws that rotate in opposite directions. This design allows for enhanced material handling and processing capabilities, making them suitable for a wide array of applications. One of the