The Role of Automation in Modern PET Sheet Extruder Machines

2025-12

The Role of Automation in Modern PET Sheet Extruder Machines

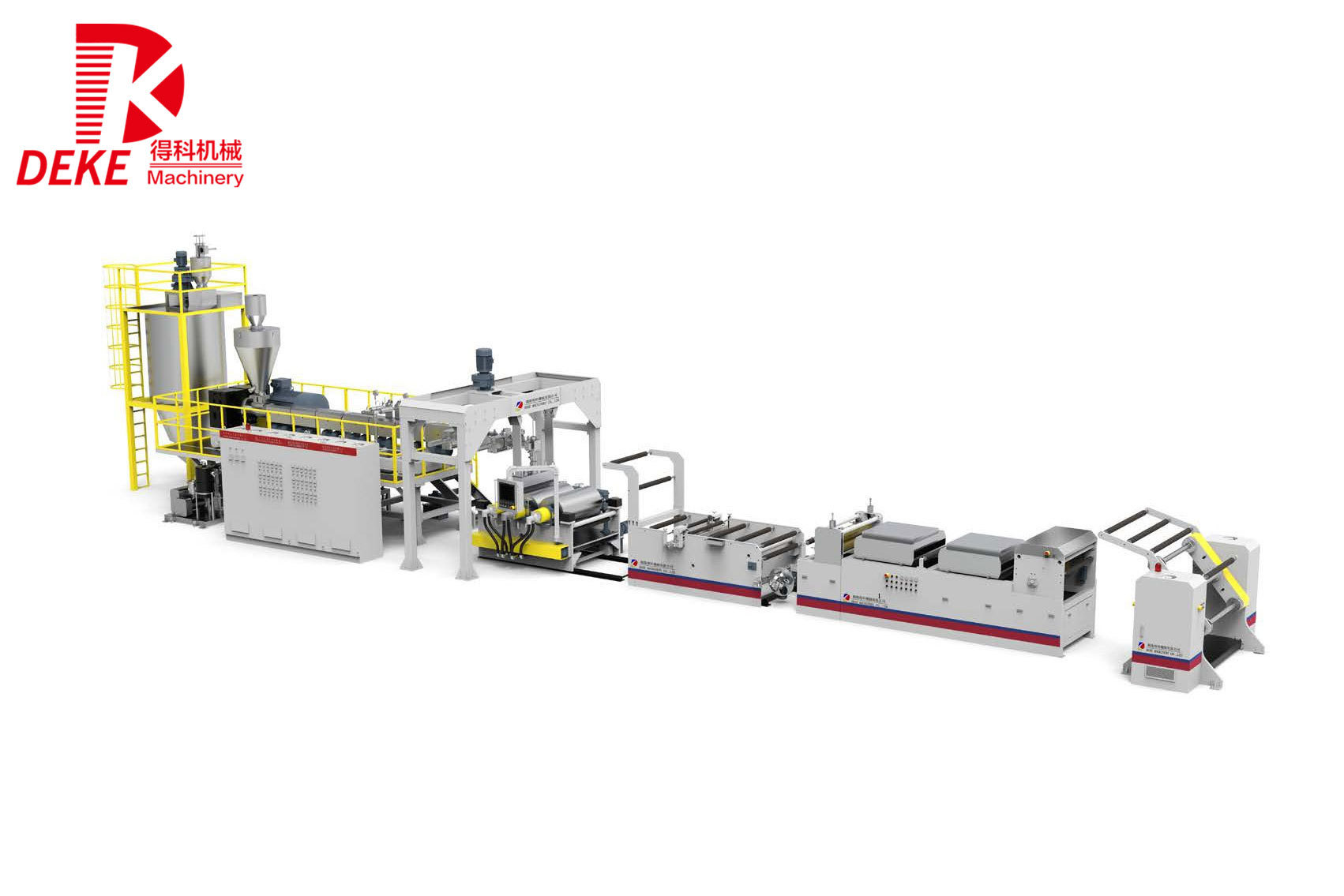

The landscape of plastic processing has seen a dramatic transformation over recent years, particularly with the integration of automation in manufacturing processes. One of the most prominent advancements has been in **Polyethylene Terephthalate (PET) sheet extruder machines**. These machines are vital in producing PET sheets used across various industries, from food packaging to automotive components. In this article, we will explore the significant role automation plays in modern PET sheet extruder machines, focusing on its impact on efficiency, quality, and sustainability.

Table of Contents

1. Introduction to PET Sheet Extrusion

2. The Importance of Automation in Manufacturing

3. How Automation Works in PET Sheet Extruder Machines

4. Benefits of Automated PET Sheet Extrusion

- 4.1 Increased Efficiency

- 4.2 Quality Improvement

- 4.3 Cost Reduction

- 4.4 Flexibility and Innovation

5. Challenges in Implementing Automation

6. The Future of Automation in PET Sheet Extrusion

7. Conclusion

8. FAQs

Introduction to PET Sheet Extrusion

PET sheet extrusion is a process where PET resin is melted and formed into sheets through an extrusion process. This method is widely recognized for producing high-strength, lightweight sheets that are clear, rigid, and offer excellent dimensional stability. The traditional extrusion process, however, can be labor-intensive and prone to human error, which is where automation comes into play.

The Importance of Automation in Manufacturing

Automation in manufacturing involves the use of control systems for operating equipment in various applications, including machinery, processes in factories, boilers, and heat treating ovens. In the context of PET sheet extrusion, automation simplifies complex processes, reduces manual labor, and enhances overall production efficiency. As industries strive to meet the demands of increasingly competitive markets, automation has become a crucial element in maintaining productivity and quality.

How Automation Works in PET Sheet Extruder Machines

Automated PET sheet extruder machines utilize advanced technologies such as **Programmable Logic Controllers (PLCs)**, **Human-Machine Interfaces (HMIs)**, and **sensors** to control various elements of the extrusion process.

- **PLCs** serve as the brain of the operation, managing inputs and outputs to ensure the machine functions correctly.

- **HMIs** allow operators to interact with the machine easily, providing real-time data and monitoring capabilities.

- **Sensors** play a pivotal role in detecting material flow, temperature, and pressure, allowing for adjustments to be made automatically to maintain optimal conditions.

Together, these components create a streamlined process that enhances throughput while minimizing the risk of human error.

Benefits of Automated PET Sheet Extrusion

As industries increasingly adopt automation, the benefits become clear. Here are some of the most significant advantages of automated PET sheet extrusion processes.

Increased Efficiency

Automation significantly boosts production efficiency by reducing cycle times and increasing output. Modern automated machines can operate continuously, with minimal downtime for maintenance. This continuous operation allows manufacturers to meet high volume demands without sacrificing quality.

Quality Improvement

With automation, the precision in the extrusion process improves dramatically. Automated systems ensure consistent temperatures, pressures, and material flow, resulting in uniform sheet quality. This consistent quality minimizes defects and waste, leading to better end products that meet strict industry standards.

Cost Reduction

Although the initial investment in automated machinery can be substantial, the long-term cost savings are significant. Automation reduces labor costs, as fewer personnel are required to operate the machinery. Additionally, the enhanced efficiency and reduced waste contribute to lower material costs, making automated PET sheet extrusion a cost-effective solution.

Flexibility and Innovation

Modern automated PET sheet extruder machines are designed with flexibility in mind. They can easily adapt to various production requirements, including different sheet sizes and thicknesses. This adaptability fosters innovation, allowing manufacturers to experiment with new products and materials without the need for significant machinery investments.

Challenges in Implementing Automation

While the benefits of automation in PET sheet extrusion are compelling, challenges do exist. One of the primary hurdles is the upfront investment required for automated systems, which can be daunting for small to medium-sized enterprises. Additionally, there may be resistance to change from employees accustomed to traditional methods.

To address these challenges, companies can consider phased implementations of automation. Starting with less complex processes allows firms to adapt gradually and understand the benefits before committing to comprehensive automation.

The Future of Automation in PET Sheet Extrusion

The future of automation in PET sheet extrusion looks promising, with ongoing advancements in technology. Innovations like the Internet of Things (IoT) and **Artificial Intelligence (AI)** are set to further revolutionize the industry. IoT can provide real-time data analytics, enabling predictive maintenance and reducing downtime. Meanwhile, AI can optimize production processes by analyzing data patterns and making adjustments autonomously.

As these technologies continue to evolve, we can anticipate even greater efficiencies and capabilities in PET sheet extrusion, positioning manufacturers to meet future challenges head-on.

Conclusion

The integration of automation into modern PET sheet extruder machines represents a significant leap forward for the plastic processing industry. By enhancing efficiency, improving quality, and reducing costs, automation is reshaping how manufacturers approach production. While challenges remain, the future of automation in PET extrusion appears bright, driven by continuous technological advancements. As we move forward, embracing automation will be critical for businesses aiming to thrive in an increasingly competitive landscape.

FAQs

1. What is PET sheet extrusion?

PET sheet extrusion is a manufacturing process that involves melting PET resin and forming it into sheets for various applications, including packaging and automotive parts.

2. How does automation improve PET sheet extrusion?

Automation improves PET sheet extrusion by increasing production efficiency, enhancing product quality, reducing costs, and allowing for greater flexibility in manufacturing.

3. What are the key components of an automated PET sheet extruder?

Key components include Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and sensors that monitor various aspects of the extrusion process.

4. What challenges do companies face when implementing automation?

Challenges include the initial investment costs, potential resistance from employees, and the need for appropriate training and support.

5. What does the future hold for automation in the plastic processing industry?

The future is likely to see greater integration of IoT and AI technologies, leading to even more efficient production processes and higher-quality products.

RELATED INFORMATION

Why Choose Conical Twin Screw for Your Next Extrusion Project?

Why Choose Conical Twin Screw for Your Next Extrusion Project? Understanding Extrusion Technology In the realm of **plastic processing**, extrusion is an essential manufacturing technique that transforms raw plastic materials into usable products. The **extrusion process** involves forcing molten plastic through a die to create continuous shapes like sheets, films, and profiles. With advancements

Understanding the Advantages of Counter Rotating Twin Screw Extruders for Plastic Processing

Counter rotating twin screw extruders are pivotal in the plastic processing industry, recognized for their versatility and efficiency. Unlike single screw extruders, twin screw extruders feature two intermeshing screws that rotate in opposite directions. This design allows for enhanced material handling and processing capabilities, making them suitable for a wide array of applications. One of the