Top Trends in Plastic Extrusion: The Rise of PET Sheet Technology

2025-12

Top Trends in Plastic Extrusion: The Rise of PET Sheet Technology

Introduction to Plastic Extrusion and PET Sheets

Plastic extrusion has become a cornerstone of modern manufacturing, enabling the production of diverse plastic products with high efficiency. Among the various materials processed, **Polyethylene Terephthalate** (PET) has gained significant traction, especially in the form of sheets. This article delves into the top trends surrounding plastic extrusion, with a particular emphasis on the burgeoning technology of PET sheet production.

The Significance of PET in the Plastic Industry

The rise of PET sheets is not merely a trend but a response to growing demands for sustainable and versatile materials in the plastic industry. Characterized by excellent chemical resistance, durability, and recyclability, PET sheets are increasingly favored in various applications ranging from packaging to construction.

Understanding PET: Properties and Benefits

PET is renowned for its favorable properties, which include:

- **Chemical Resistance**: PET exhibits high resistance to a wide range of chemicals, making it suitable for various applications.

- **Mechanical Strength**: The strength-to-weight ratio of PET is impressive, allowing for lightweight yet sturdy products.

- **Clarity and Aesthetic Appeal**: PET sheets can be produced with high clarity, making them perfect for applications needing visibility and aesthetics, such as displays and signage.

- **Recyclability**: As environmental concerns rise, PET stands out due to its recyclable nature, facilitating a circular economy in plastic usage.

Current Trends in PET Sheet Technology

The landscape of PET sheet technology is constantly evolving. Here are some of the most notable trends shaping this sector:

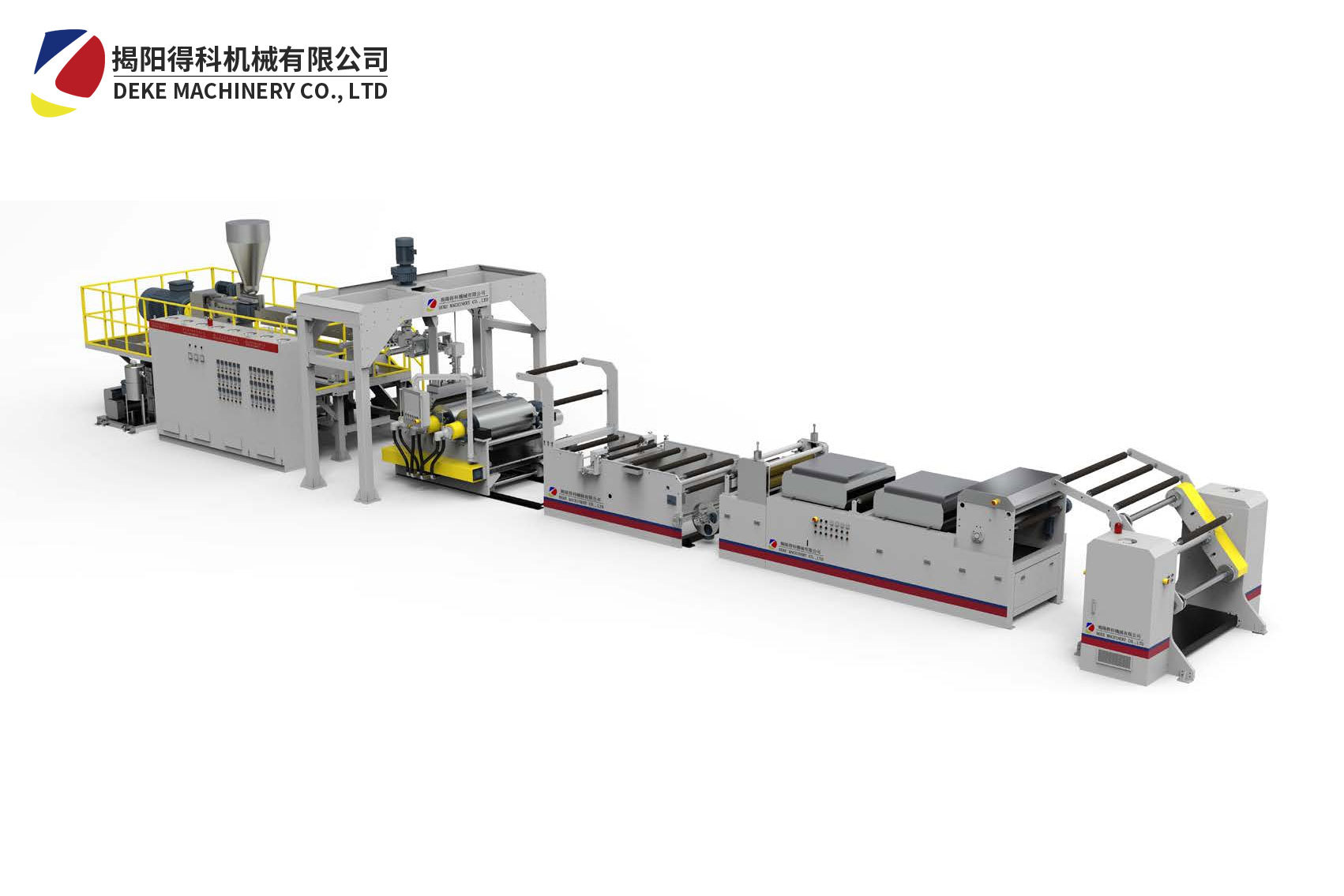

1. Advancements in Extrusion Technology

Continuous improvements in extrusion machinery and processes have enabled manufacturers to produce high-quality PET sheets more efficiently. Innovations such as **co-extrusion technology** allow for multi-layer sheets that combine the benefits of different materials, enhancing performance and functionality.

Enhanced Process Control

Modern extrusion lines are equipped with advanced process control systems, ensuring consistent quality and reducing waste. Real-time monitoring and automation streamline production, enhancing efficiency and reducing downtime.

2. Eco-Friendly Production Practices

As sustainability becomes a priority, manufacturers are adopting eco-friendly practices in PET sheet production. This includes utilizing recycled PET (rPET) and minimizing energy consumption during manufacturing.

The Role of Recycled PET (rPET)

The incorporation of rPET not only supports sustainability efforts but also meets consumer demand for environmentally friendly products. The ability to produce high-quality sheets from recycled materials is a game-changer in the industry.

3. Customization and Versatility

The ability to customize PET sheets for specific applications has become increasingly important. Manufacturers are offering tailored solutions, such as varying thicknesses, finishes, and coatings, catering to diverse industry needs.

Applications Across Industries

From packaging and electronics to automotive and construction, the versatility of PET sheets allows them to adapt to numerous applications, enhancing their market appeal.

4. Innovations in Coating Technologies

The development of advanced coating technologies is expanding the functionality of PET sheets. Anti-fog, anti-scratch, and UV-resistant coatings enhance performance in specific applications, boosting durability and usability.

Industry Applications of PET Sheets

The application of PET sheets spans various industries, showcasing their adaptability and functionality. Here are some prominent sectors leveraging PET sheet technology:

1. Packaging Industry

PET sheets play a pivotal role in the packaging sector, used in products such as blister packs, containers, and food packaging. Their clarity and strength make them ideal for preserving product integrity while enhancing visual appeal.

2. Construction and Building

In construction, PET sheets are utilized for glazing, skylights, and protective barriers. Their lightweight nature and resistance to weather conditions make them a preferable choice for various building applications.

3. Electronics and Displays

The electronics industry benefits from PET sheets in the production of displays, touchscreens, and insulation materials. The optical clarity and durability of PET contribute to better performance in electronic devices.

4. Automotive Sector

In the automotive industry, PET sheets are employed in interior and exterior applications, including dashboards, window glazing, and protective covers. Their lightweight and high-strength properties contribute to improved vehicle efficiency.

Challenges Facing PET Sheet Technology

Despite the advancements, several challenges must be addressed to fully harness the potential of PET sheet technology.

1. Cost of Production

While advancements are being made, the cost of producing high-quality PET sheets can still be significant. Manufacturers are continually seeking ways to optimize production processes to reduce costs.

2. Recycling and Sustainability Concerns

While PET is recyclable, the effectiveness of recycling efforts varies. Ensuring a robust recycling infrastructure and consumer awareness is crucial for maximizing the environmental benefits of PET sheets.

3. Competition from Alternative Materials

The rise of alternative materials such as bio-based plastics and composites poses competition for PET sheets. Manufacturers must continue innovating to remain competitive.

Future Directions for PET Sheet Technology

As we look ahead, several future directions for PET sheet technology emerge.

1. Integration of Smart Technologies

The integration of smart technologies, such as sensors and IoT capabilities, into PET sheets may offer enhanced functionality for applications requiring real-time data monitoring.

2. Advances in Biodegradable Options

The development of biodegradable PET alternatives could pave the way for a new era in sustainability, addressing environmental concerns while maintaining the desirable properties of traditional PET.

3. Expanding Global Markets

As global demand for PET sheets grows, emerging markets present significant opportunities for expansion. Manufacturers must adapt to local market needs and preferences to capitalize on these prospects.

Conclusion

In summary, the rise of PET sheet technology represents a significant trend in the plastic extrusion industry. With advancements in production processes, a focus on sustainability, and diverse applications across multiple sectors, PET sheets are set to play an essential role in shaping the future of plastic manufacturing. By staying informed on these trends and innovations, companies can position themselves competitively in the evolving landscape of plastic processing.

FAQs

1. What are the primary benefits of using PET sheets in manufacturing?

PET sheets offer advantages such as chemical resistance, durability, clarity, and recyclability, making them ideal for various applications.

2. How are PET sheets produced?

PET sheets are produced through a process called extrusion, where melted PET is shaped into sheets through a die and then cooled.

3. Can PET sheets be recycled?

Yes, PET sheets are recyclable and can be reprocessed into new products, contributing to a circular economy.

4. What industries utilize PET sheet technology?

PET sheets are widely used in industries such as packaging, construction, electronics, and automotive.

5. What challenges exist in PET sheet production?

Challenges include production costs, recycling effectiveness, and competition from alternative materials.

Previous Page:

RELATED INFORMATION

Top Trends in Plastic Extrusion: The Rise of PET Sheet Technology

Top Trends in Plastic Extrusion: The Rise of PET Sheet Technology Introduction to Plastic Extrusion and PET Sheets Plastic extrusion has become a cornerstone of modern manufacturing, enabling the production of diverse plastic products with high efficiency. Among the various materials processed, **Polyethylene Terephthalate** (PET) has gained significant traction, especially in the form of sheets.

Unlocking the Potential of PET Twin Screw Extruders in Plastic Processing

The PET twin screw extruder is a critical machine in the field of plastic processing, particularly known for its ability to handle a variety of polymer materials with precision and efficiency. This advanced piece of equipment utilizes two intermeshing screws to facilitate the melting, mixing, and pumping of thermoplastic materials. The design and operational capabilities of twin screw extruders ha