Understanding PET Sheet Extruders: Key Insights for Industry Professionals

2025-11

The PET sheet extruder is a vital component in the realm of plastic processing machinery, specifically designed for the extrusion of polyethylene terephthalate (PET) sheets. These sheets are widely utilized across various industries, including packaging, construction, and automotive, due to their exceptional clarity, strength, and recyclability. Understanding the operational mechanics and benefits of using PET sheet extruders can significantly impact production efficiency and product quality.

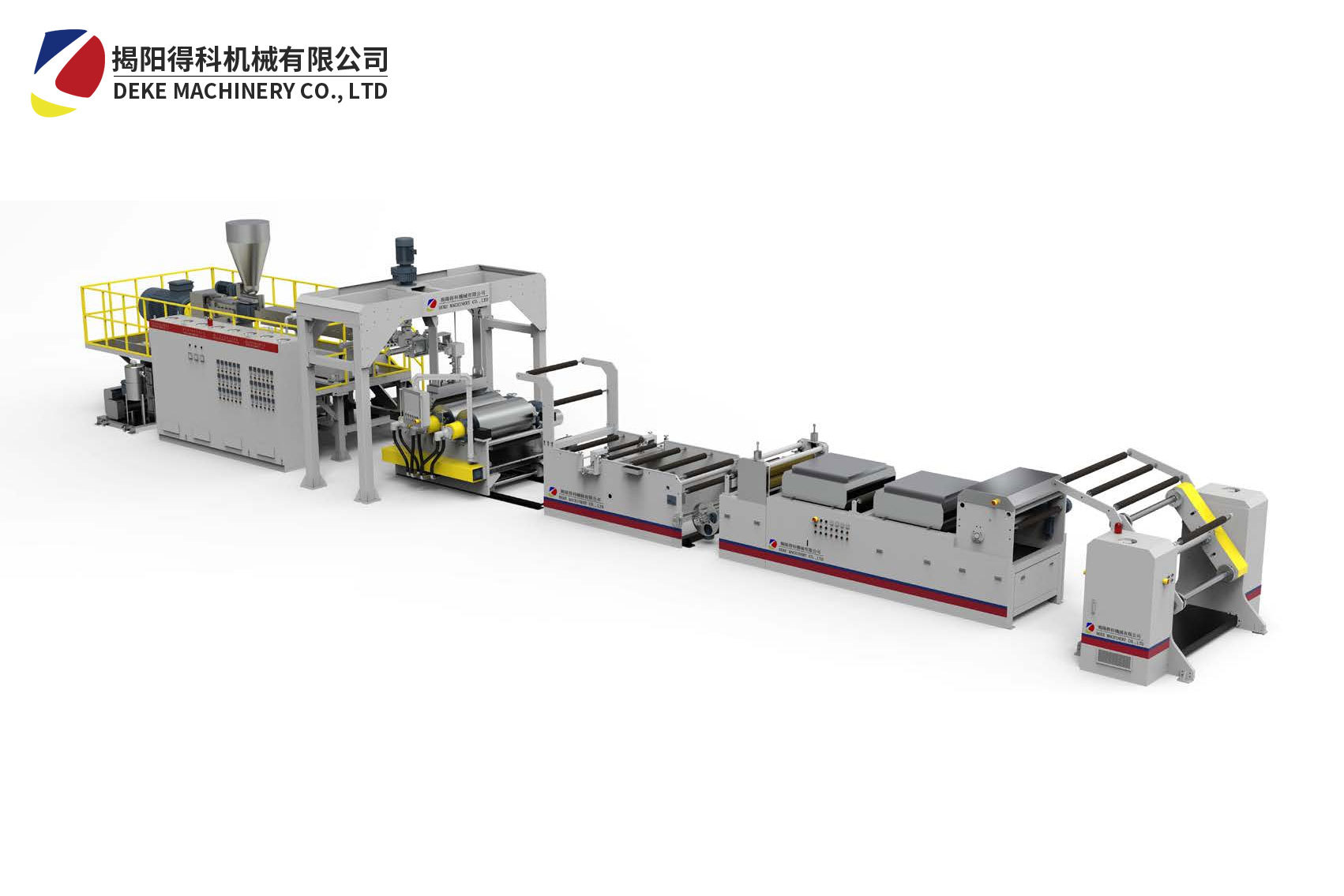

At its core, the PET sheet extruder operates by melting raw PET pellets and forcing the molten material through a die to create sheets of desired thickness. This process involves precise temperature control and consistent feed rates, ensuring that the properties of the PET material remain intact. The extruder typically comprises several critical components, including the hopper, barrel, screw, and die, each playing a significant role in the extrusion process.

One of the primary advantages of PET sheet extrusion is its ability to produce thin, lightweight sheets that maintain high mechanical strength and thermal stability. This makes them ideal for applications requiring transparency and durability, such as food packaging, where visibility of the product is crucial. Additionally, PET sheets are inherently recyclable, aligning with the growing demand for sustainable materials in the manufacturing sector.

To optimize the performance of PET sheet extruders, it is important to consider several factors. First, ensuring the correct temperature settings throughout the extrusion process is essential for achieving the desired quality. Inadequate temperature control can lead to improper melting, causing defects in the final product. Moreover, the choice of additives or modifications to the PET formulation can enhance the properties of the extruded sheets, such as improving UV resistance or enhancing flexibility.

Another critical factor is the maintenance of the extruder itself. Regular cleaning and inspection of the screw, barrel, and die can prevent material build-up and ensure smooth operation. Implementing a scheduled maintenance program is an effective way to minimize downtime and extend the lifespan of the equipment.

In conclusion, understanding the intricacies of PET sheet extruders and their operational parameters is crucial for professionals in the plastic processing industry. By optimizing the extrusion process and maintaining equipment effectively, manufacturers can produce high-quality PET sheets that meet the demands of various applications while contributing to sustainable practices in material use. Investing in knowledge about PET sheet extrusion can ultimately lead to improved production outcomes and greater market competitiveness.

RELATED INFORMATION

How PET Sheet Extruders Revolutionize Plastic Processing Machinery

How PET Sheet Extruders Revolutionize Plastic Processing Machinery Table of Contents Introduction to PET Sheet Extruders Understanding Plastic Processing Machinery The Technology Behind PET Sheet Extruders Advantages of Using PET Sheet Extruders Sustainability in Plastic Manufacturing Applications of PET Sheets in Various Industries Future Trends in PET Sheet Extrusion

PET sheet extruder machines play a crucial role in the field of plastic processing, specifically in the production of polyethylene terephthalate (PET) sheets. These machines are designed to melt and extrude PET resin into sheets of varying thickness, which are then used in a variety of applications such as packaging, construction, and consumer goods. Understanding how these machines work and their