An In-Depth Look at the Technical Specifications of PET Sheet Extruder Machines

2025-11

An In-Depth Look at the Technical Specifications of PET Sheet Extruder Machines

Table of Contents

- Introduction to PET Sheet Extruder Machines

- Understanding PET: Properties and Applications

- The Extrusion Process: A Step-by-Step Guide

- Key Technical Specifications of PET Sheet Extruder Machines

- Performance Metrics: What to Look For

- Energy Efficiency and Sustainability Considerations

- Maintenance Tips for Optimal Performance

- Future Trends in PET Sheet Extrusion Technology

- Conclusion

- Frequently Asked Questions

Introduction to PET Sheet Extruder Machines

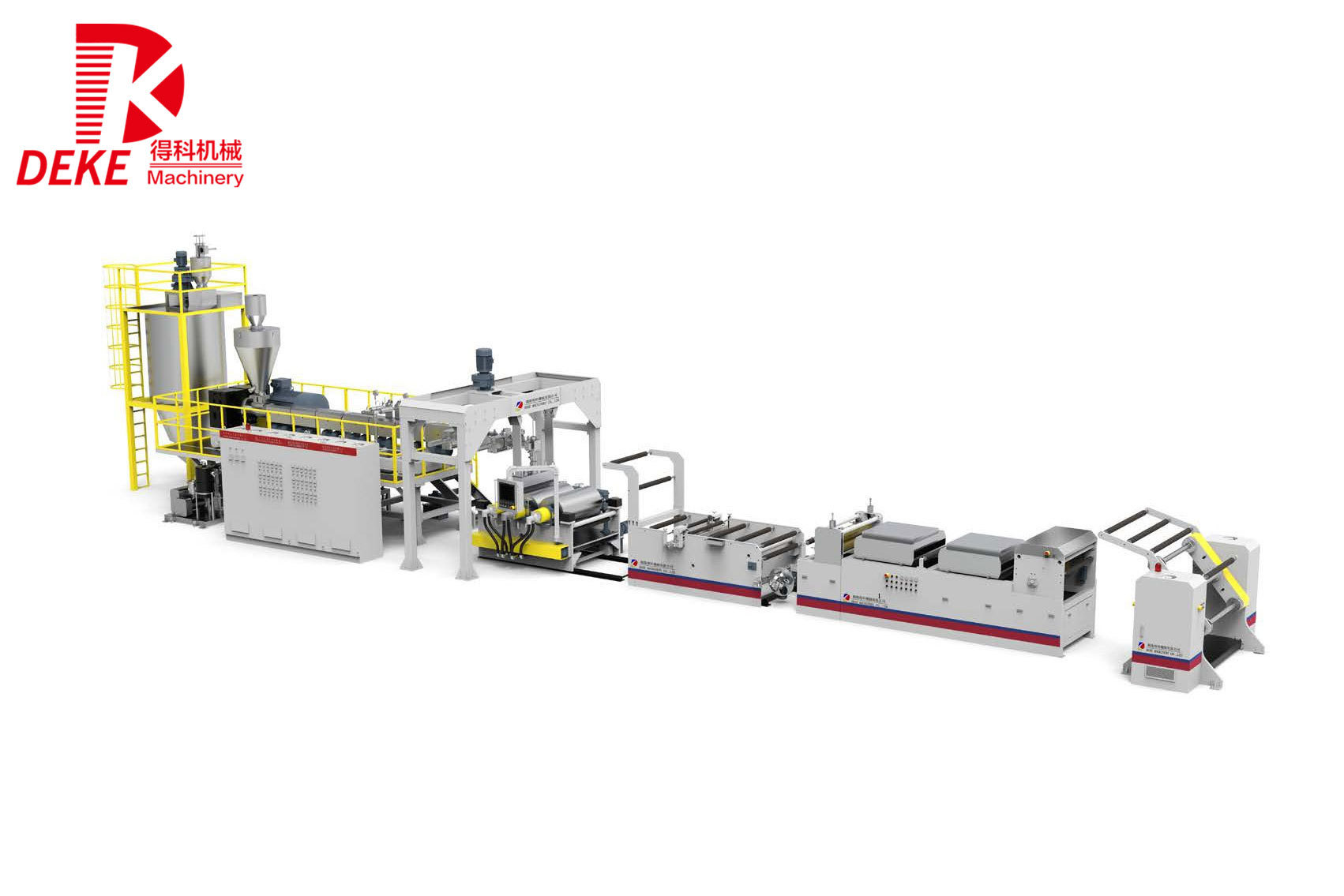

In the realm of plastic manufacturing, **PET sheet extruder machines** play a pivotal role. These machines are designed to produce high-quality sheets of polyethylene terephthalate (PET), a versatile material widely used in packaging, automotive, and consumer goods industries. Understanding the technical specifications of these machines is crucial for manufacturers aiming to optimize production efficiency and product quality.

Understanding PET: Properties and Applications

**Polyethylene Terephthalate (PET)** is a thermoplastic polymer that exhibits excellent mechanical properties, chemical resistance, and dimensional stability. Its transparency and gloss make it an ideal choice for various applications, including:

- **Food packaging**: PET is commonly used in beverage bottles and food containers due to its safety and barrier properties.

- **Thermal insulation**: Its low thermal conductivity makes PET sheets suitable for insulation applications.

- **Consumer goods**: Products like electronics and automotive parts often utilize PET sheets for their durability and aesthetic appeal.

By recognizing the diverse applications of PET, one can appreciate the significance of **high-performance PET sheet extruder machines** that meet industry demands.

The Extrusion Process: A Step-by-Step Guide

The extrusion process for producing PET sheets involves several key stages:

1. **Material Feeding**: PET resin pellets are fed into a hopper and then into the extruder.

2. **Melting**: The pellets are heated to their melting point, allowing them to transform into a viscous liquid.

3. **Extrusion**: The molten PET is forced through a die to form a continuous sheet.

4. **Cooling**: The extruded sheet is rapidly cooled using air or water to solidify its structure.

5. **Cutting and Winding**: Finally, the cooled sheets are cut to size and wound onto rolls for further processing.

Understanding this process helps manufacturers pinpoint areas for improvement and efficiency.

Key Technical Specifications of PET Sheet Extruder Machines

When evaluating PET sheet extruder machines, several **technical specifications** must be considered:

- **Screw Design**: The design of the screw influences the melting and mixing process. A high-quality, multi-stage screw ensures uniform melting and optimal output.

- **Barrel Length-to-Diameter Ratio (L/D Ratio)**: A higher L/D ratio typically indicates better mixing and more efficient processing.

- **Temperature Zones**: Modern machines feature multiple heating zones to ensure precise temperature control throughout the extrusion process.

- **Die Design**: The design of the die is critical for determining the thickness and width of the PET sheets produced.

- **Output Rate**: Measured in kilograms per hour (kg/h), the output rate indicates the machine's efficiency and productivity.

- **Drive System**: The type of drive system (electric, hydraulic, or hybrid) can impact energy consumption and operational costs.

By examining these specifications, manufacturers can select machines that align with their production requirements.

Performance Metrics: What to Look For

To ensure the best performance from PET sheet extruder machines, consider the following metrics:

- **Production Speed**: The ability to produce sheets quickly without compromising quality is essential for maintaining competitiveness.

- **Sheet Thickness Consistency**: Variability in sheet thickness can lead to waste and increased costs. Machines should maintain strict tolerances.

- **Energy Consumption**: Efficient machines minimize energy usage while maximizing output, contributing to lower operational costs.

- **Downtime**: Machines with lower downtime rates enhance productivity and profitability.

- **Maintenance Requirements**: Easy-to-maintain machines reduce operational interruptions and improve longevity.

Energy Efficiency and Sustainability Considerations

In today’s environmentally conscious market, **energy efficiency** is a significant factor in selecting PET sheet extruder machines. Manufacturers are increasingly seeking machines that not only reduce energy consumption but also incorporate sustainable practices. This includes:

- **Variable Frequency Drives (VFDs)**: VFDs can optimize motor speed according to the workload, significantly cutting down energy use.

- **Heat Recovery Systems**: Utilizing waste heat from the machine for pre-heating materials can improve overall energy efficiency.

- **Sustainable Materials**: Some machines can process recycled PET, contributing to a circular economy.

Investing in energy-efficient machines not only lowers production costs but also enhances corporate responsibility.

Maintenance Tips for Optimal Performance

Regular maintenance is crucial for ensuring the longevity and efficiency of PET sheet extruder machines. Here are some essential maintenance tips:

- **Routine Checks**: Regularly inspect critical components such as the screw, barrel, and die for wear and tear.

- **Cleaning**: Keep the machine clean to prevent contamination of PET sheets and ensure consistent product quality.

- **Lubrication**: Proper lubrication of moving parts is vital for minimizing friction and wear.

- **Calibration**: Regularly calibrate temperature and pressure settings to ensure optimal performance.

- **Operator Training**: Invest in training for operators to ensure they can identify potential issues before they escalate.

Future Trends in PET Sheet Extrusion Technology

As technology advances, PET sheet extruder machines continue to evolve. Some future trends include:

- **Smart Manufacturing**: The integration of IoT (Internet of Things) technologies allows for real-time monitoring and predictive maintenance, enhancing efficiency.

- **Automation**: Increased automation in the extrusion process can minimize human error and boost productivity.

- **Bio-based PET**: The development of bio-based PET materials is gaining traction, opening new avenues for eco-friendly production.

- **Customization**: Machines that allow for easy customization of sheet properties will become more prevalent, catering to niche applications.

Conclusion

Understanding the technical specifications and performance metrics of PET sheet extruder machines is vital for manufacturers aiming to enhance productivity and product quality. By selecting the right machines and implementing best practices in maintenance and energy efficiency, businesses can not only meet current market demands but also prepare for future advancements in technology. This comprehensive knowledge ultimately supports sustainable growth in the plastic manufacturing industry.

Frequently Asked Questions

1. What is a PET sheet extruder machine?

A PET sheet extruder machine is a specialized piece of equipment designed to produce sheets made from polyethylene terephthalate (PET) through an extrusion process.

2. What are the key benefits of using PET sheets?

PET sheets offer excellent clarity, chemical resistance, and strength, making them ideal for a wide range of applications, including packaging and automotive parts.

3. How does the extrusion process work?

The extrusion process involves feeding PET resin into the machine, melting it, forcing it through a die to form sheets, and then cooling and cutting the sheets to size.

4. What factors influence the output rate of a PET sheet extruder machine?

Factors such as screw design, temperature control, and the machine's overall efficiency significantly affect the output rate.

5. How can I ensure the energy efficiency of my PET sheet extruder machine?

To enhance energy efficiency, consider incorporating variable frequency drives, heat recovery systems, and regularly maintaining the machine to minimize energy waste.

Incorporating these strategies can help manufacturers not only achieve better production outcomes but also align with sustainability goals in the plastic processing industry.

Previous Page:

RELATED INFORMATION

How PET Sheet Extruders Revolutionize Plastic Processing Machinery

How PET Sheet Extruders Revolutionize Plastic Processing Machinery Table of Contents Introduction to PET Sheet Extruders Understanding Plastic Processing Machinery The Technology Behind PET Sheet Extruders Advantages of Using PET Sheet Extruders Sustainability in Plastic Manufacturing Applications of PET Sheets in Various Industries Future Trends in PET Sheet Extrusion

PET sheet extruder machines play a crucial role in the field of plastic processing, specifically in the production of polyethylene terephthalate (PET) sheets. These machines are designed to melt and extrude PET resin into sheets of varying thickness, which are then used in a variety of applications such as packaging, construction, and consumer goods. Understanding how these machines work and their