The Comprehensive Guide to PET Sheet Extruder Machines: Understanding Their Role in Plastic Processing

2025-12

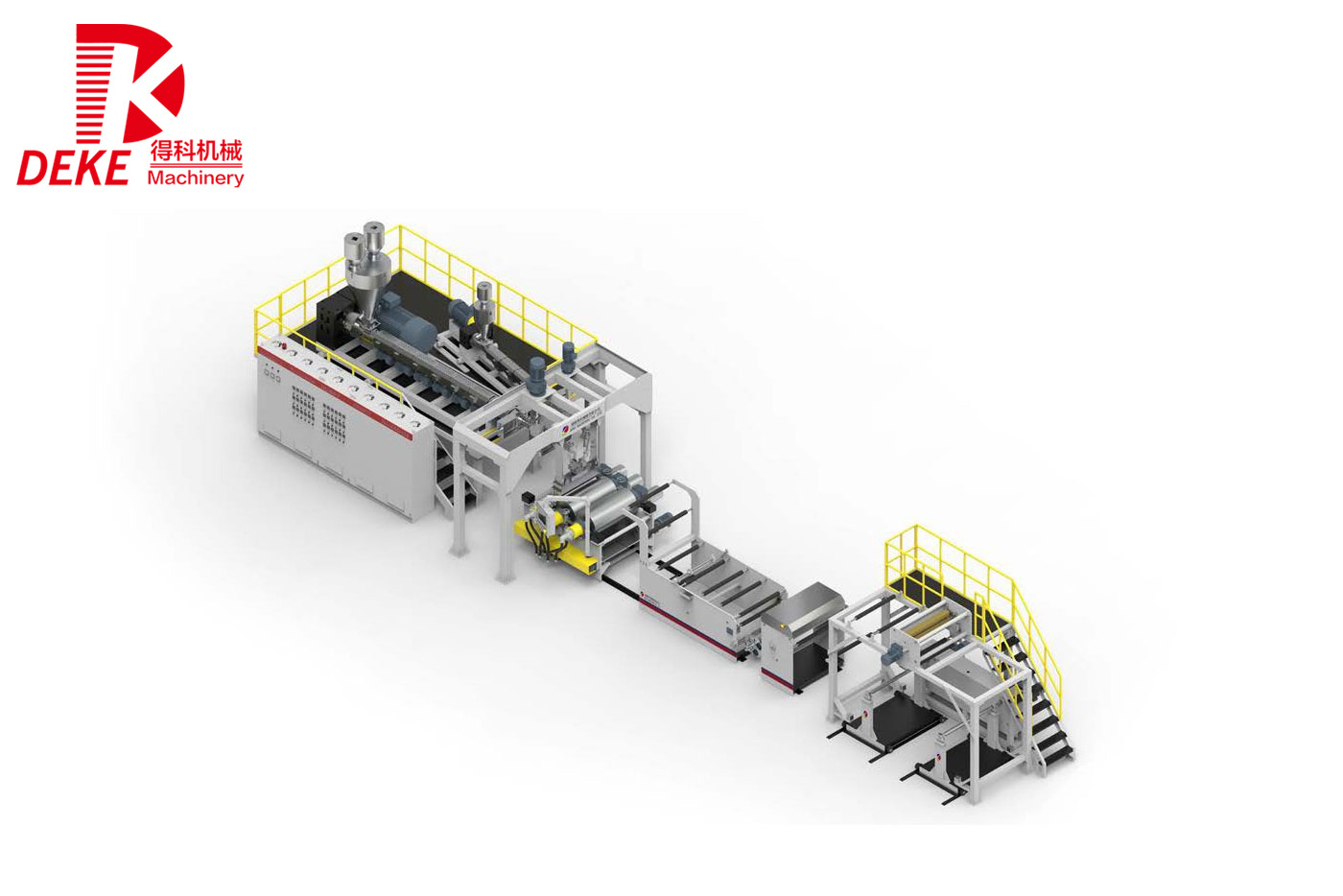

The operation of a PET sheet extruder machine involves several key components, including the extruder itself, a die, and a cooling system. The process begins with feeding PET pellets into the extruder, where they are heated to a specific temperature to achieve the melting point. As the melted PET is pushed through the screw of the extruder, it is shaped by a die that determines the thickness and width of the sheet. After exiting the die, the sheet is cooled and solidified, typically using a set of rollers or a cooling system.

One of the primary advantages of using PET sheet extruder machines is the versatility they offer. PET sheets produced from these machines can be customized to meet specific requirements, including varying thicknesses, colors, and surface finishes. This adaptability makes PET sheets suitable for a wide range of applications, from food packaging that requires high barrier properties to durable construction materials that can withstand environmental stresses.

Another benefit of PET sheet extruder machines is their efficiency and sustainability. PET is a recyclable material, and the use of PET sheets can contribute to environmentally friendly practices. Additionally, advancements in technology have led to the development of energy-efficient machines that reduce production costs while maintaining high-quality output. This is particularly important in today's market, where sustainability and cost-effectiveness are paramount.

Furthermore, the market for PET sheets is expanding rapidly due to the growing demand for sustainable packaging solutions. As consumers become more environmentally conscious, manufacturers are seeking materials that align with these values. PET sheets, being lightweight yet strong, offer an excellent alternative to traditional packaging materials, providing both durability and recyclability.

In conclusion, PET sheet extruder machines are integral to the plastic processing industry, offering numerous advantages in terms of versatility, efficiency, and sustainability. As the demand for PET sheets continues to rise, understanding the technology and processes behind these machines is essential for manufacturers looking to innovate and stay competitive in the marketplace. By harnessing the capabilities of PET sheet extruder machines, businesses can contribute to a more sustainable future while meeting the needs of a diverse range of industries.

RELATED INFORMATION

How PET Sheet Extruders Revolutionize Plastic Processing Machinery

How PET Sheet Extruders Revolutionize Plastic Processing Machinery Table of Contents Introduction to PET Sheet Extruders Understanding Plastic Processing Machinery The Technology Behind PET Sheet Extruders Advantages of Using PET Sheet Extruders Sustainability in Plastic Manufacturing Applications of PET Sheets in Various Industries Future Trends in PET Sheet Extrusion

PET sheet extruder machines play a crucial role in the field of plastic processing, specifically in the production of polyethylene terephthalate (PET) sheets. These machines are designed to melt and extrude PET resin into sheets of varying thickness, which are then used in a variety of applications such as packaging, construction, and consumer goods. Understanding how these machines work and their