Understanding Twin Screw Compounders: Key Insights for Plastic Processing Professionals

2025-11

One of the primary benefits of twin screw compounders is their ability to efficiently process materials with varying viscosities and flow characteristics. This capability is crucial for applications that require precise control over the material properties. The intermeshing design of the screws allows for effective transport and mixing of additives, fillers, and other components. As a result, manufacturers can achieve homogeneous blends and tailored material properties that meet specific application requirements.

Moreover, twin screw compounders provide exceptional temperature control. The design enables uniform heat distribution, minimizing thermal degradation of sensitive materials. This is particularly vital when working with high-performance polymers or additives that require strict processing conditions. The ability to maintain consistent processing temperatures ensures product quality and reduces the risk of production waste.

In terms of scalability, twin screw compounders offer flexibility, allowing for the adjustment of operating parameters such as screw speed and feed rates. This adaptability is crucial for manufacturers aiming to optimize production processes and meet varying product demands. The modular design of some twin screw systems further enhances this flexibility, making it easier to adapt to different formulations or production volumes without significant downtime.

Furthermore, twin screw compounders are equipped with advanced control systems that enable real-time monitoring and adjustment of processing conditions. These systems enhance the precision of the compounding process and provide valuable data for quality assurance. Manufacturers can implement predictive maintenance strategies based on this data, reducing the likelihood of unexpected downtime and improving overall operational efficiency.

While twin screw compounders are highly advantageous, it is essential to consider the specific requirements of your application when selecting equipment. Factors such as material properties, production volume, and desired product characteristics should all play a critical role in the decision-making process.

In summary, twin screw compounders represent a cornerstone technology in the plastic processing industry. Their ability to handle diverse materials, maintain precise temperature control, and adapt to varying production needs makes them invaluable for modern manufacturing applications. By leveraging the unique capabilities of twin screw compounders, professionals in the plastic processing sector can enhance product quality and operational efficiency, paving the way for innovation and growth in their respective markets.

RELATED INFORMATION

How PET Sheet Extruders Revolutionize Plastic Processing Machinery

How PET Sheet Extruders Revolutionize Plastic Processing Machinery Table of Contents Introduction to PET Sheet Extruders Understanding Plastic Processing Machinery The Technology Behind PET Sheet Extruders Advantages of Using PET Sheet Extruders Sustainability in Plastic Manufacturing Applications of PET Sheets in Various Industries Future Trends in PET Sheet Extrusion

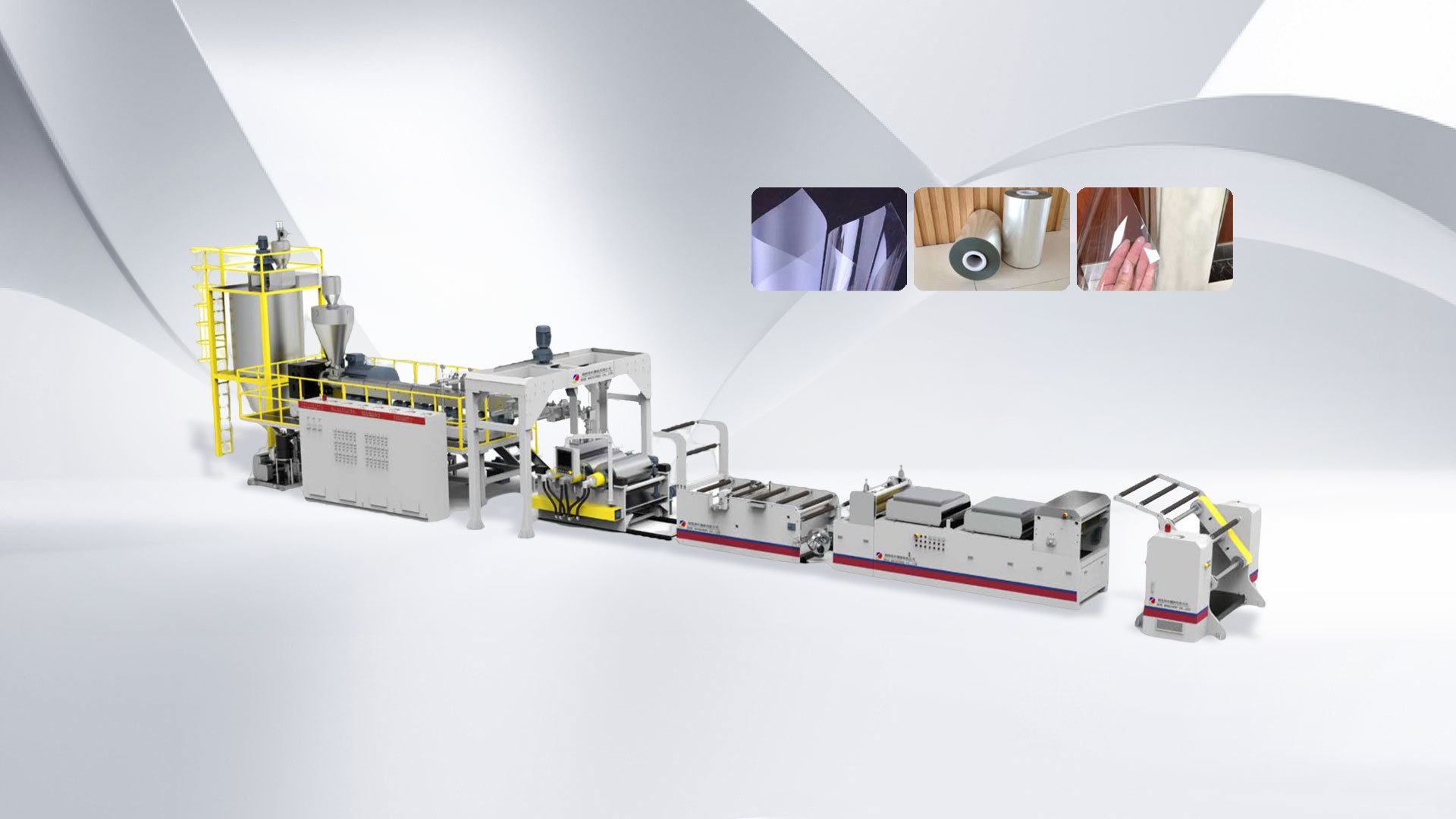

PET sheet extruder machines play a crucial role in the field of plastic processing, specifically in the production of polyethylene terephthalate (PET) sheets. These machines are designed to melt and extrude PET resin into sheets of varying thickness, which are then used in a variety of applications such as packaging, construction, and consumer goods. Understanding how these machines work and their