How PET Twin Screw Extruders Can Revolutionize Your Production Line

2025-11

How PET Twin Screw Extruders Can Revolutionize Your Production Line

Table of Contents

- Introduction to PET Twin Screw Extruders

- Understanding the Technology Behind Twin Screw Extruders

- Advantages of PET Twin Screw Extruders

- Key Applications of PET Twin Screw Extruders

- Energy Efficiency and Sustainability in Production

- Choosing the Right PET Twin Screw Extruder for Your Needs

- Future Trends in Extrusion Technology

- Frequently Asked Questions

- Conclusion

Introduction to PET Twin Screw Extruders

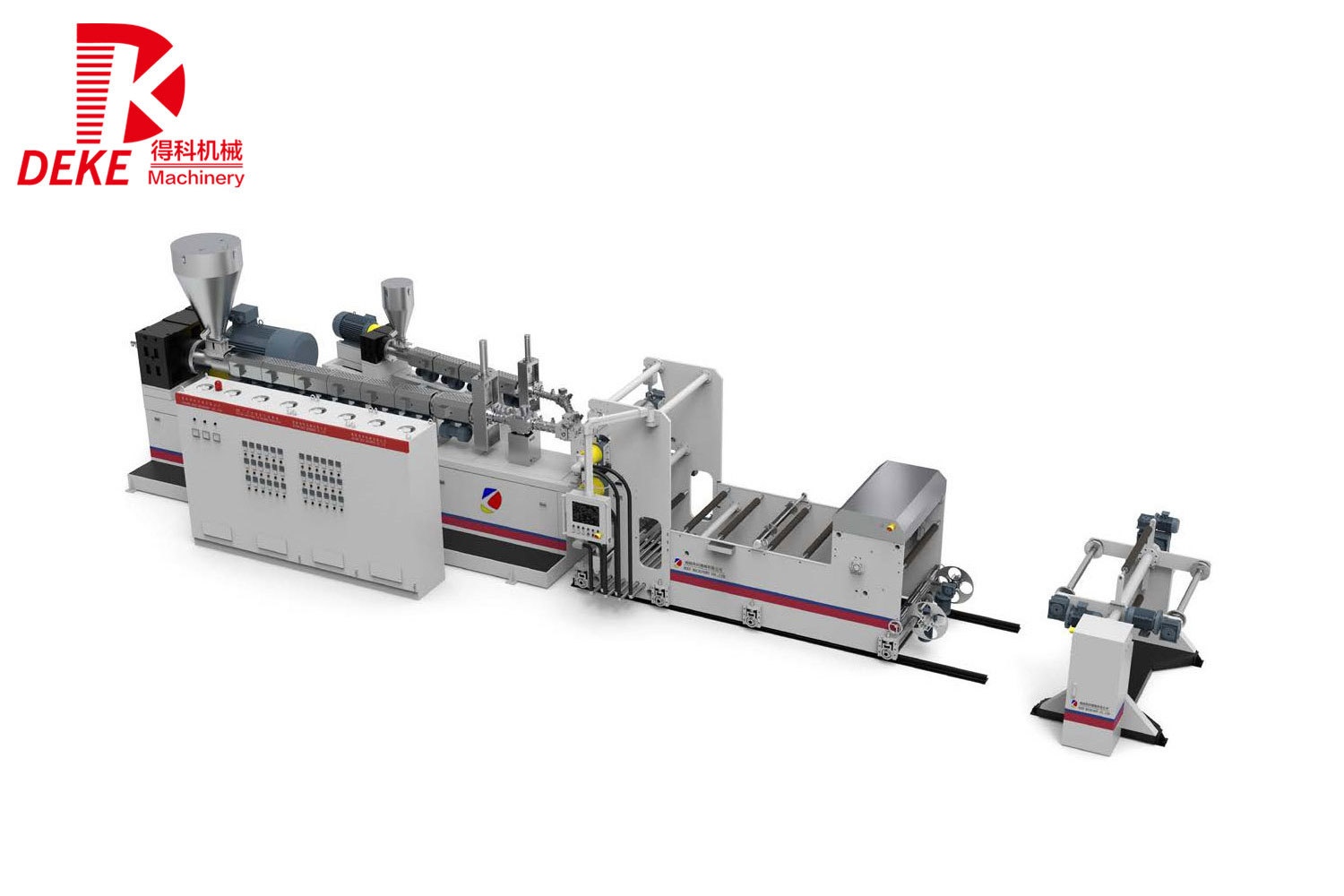

In today’s competitive manufacturing landscape, companies are constantly seeking innovative ways to enhance their production processes. One technology that has gained prominence is the **PET twin screw extruder**. This advanced machinery not only optimizes the production line but also integrates seamlessly with other systems, resulting in **higher efficiency**, **lower costs**, and **better product quality**. In this article, we delve deep into how PET twin screw extruders can revolutionize your manufacturing operations.

Understanding the Technology Behind Twin Screw Extruders

PET twin screw extruders consist of two intermeshing screws that operate in a synchronized manner. This unique design allows for better mixing, kneading, and conveying of materials compared to single-screw extruders. The key components of a twin screw extruder include:

1. Screw Design

The screws in twin screw extruders are typically designed with varying geometries to optimize the processing of PET. The design can impact the shear rate, mixing efficiency, and thermal distribution, making it critical for producing high-quality outputs.

2. Barrel Configuration

The barrel housing the screws can be configured with temperature control zones, allowing for precise thermal management during the extrusion process. This feature is particularly important when processing thermoplastic materials like PET.

3. Feed Systems

Efficient feeding systems ensure a consistent input of raw materials into the extruder, leading to uniform material properties in the final products. The feed system can be customized based on the type of PET and additives being used.

4. Control Systems

Modern PET twin screw extruders are equipped with advanced control systems that allow for real-time monitoring and adjustments. This capability ensures optimal processing conditions and can minimize downtime due to equipment malfunctions.

Advantages of PET Twin Screw Extruders

Investing in PET twin screw extruders can yield numerous benefits for manufacturers. Some of the primary advantages include:

1. Enhanced Mixing and Compounding

The intermeshing design of twin screws provides superior mixing capabilities, enabling the incorporation of additives, colorants, and fillers into PET with exceptional uniformity. This leads to products with consistent quality and performance.

2. Greater Processing Flexibility

Twin screw extruders are capable of handling a wide range of materials, including virgin PET, recycled PET, and various additives. This flexibility allows manufacturers to adapt quickly to market changes and customer demands.

3. Improved Energy Efficiency

Due to their design, twin screw extruders can achieve higher throughput rates with lower energy consumption compared to single-screw extruders. This energy efficiency translates to cost savings and a reduced environmental footprint.

4. Superior Thermal Management

The ability to control temperature zones in the barrel helps maintain optimal processing conditions. This feature is crucial for PET, as improper thermal management can lead to degradation and loss of material properties.

5. Reduced Cycle Times

The efficient mixing and processing capabilities of PET twin screw extruders contribute to faster cycle times, allowing manufacturers to increase output without compromising quality.

Key Applications of PET Twin Screw Extruders

The versatility of PET twin screw extruders makes them suitable for a variety of applications in the plastics industry. Some notable applications include:

1. Production of PET Sheets and Films

PET twin screw extruders can produce high-quality sheets and films used in packaging, consumer goods, and automotive components. The excellent mixing capabilities ensure consistent color and material properties.

2. Manufacturing of PET Bottles

Extrusion blow molding techniques utilizing twin screw extruders allow for the efficient production of PET bottles. The precise control over the extrusion process leads to lightweight yet strong bottles.

3. Compounding with Recycled PET

With the increasing demand for sustainability, PET twin screw extruders play a crucial role in compounding recycled PET. The superior mixing capabilities ensure that recycled materials maintain high performance and quality.

4. Production of Masterbatches

Masterbatches are concentrated mixtures of pigments and additives that enhance the properties of PET. Twin screw extruders provide the necessary shear and mixing to create high-quality masterbatches for various applications.

Energy Efficiency and Sustainability in Production

In the era of sustainability, energy efficiency is paramount for manufacturers. PET twin screw extruders contribute to greener production processes through:

1. Lower Energy Consumption

The efficient design of twin screw extruders can result in significant energy savings compared to traditional extruders. This reduction in energy consumption not only lowers operational costs but also reduces the carbon footprint of production.

2. Reduced Waste Generation

The precision of twin screw extruders minimizes material waste during production. This efficiency aligns with the lean manufacturing principles aimed at reducing excess and improving resource utilization.

3. Recycling and Reusing Materials

With the ability to process recycled materials, PET twin screw extruders support the circular economy. By efficiently utilizing recycled PET, manufacturers can help reduce the demand for virgin resources.

Choosing the Right PET Twin Screw Extruder for Your Needs

Selecting the appropriate PET twin screw extruder for your operation involves several considerations:

1. Production Volume

Assess your production volume requirements to determine the necessary size and configuration of the extruder. Higher volumes may require larger, more robust machines.

2. Material Compatibility

Ensure that the chosen extruder can handle the specific types of PET and any additives you intend to use. Compatibility is crucial for maintaining product quality.

3. Customization Options

Look for manufacturers that offer customization options, allowing you to tailor the extruder to your unique production requirements, including screw design and barrel configuration.

4. Technical Support and Maintenance

Choose a supplier that provides comprehensive technical support and maintenance services. Proper upkeep is essential for ensuring the longevity and efficiency of your equipment.

Future Trends in Extrusion Technology

As technology evolves, the extrusion industry is witnessing several exciting trends that will shape the future of PET twin screw extruders:

1. Industry 4.0 Integration

The integration of Industry 4.0 technologies, such as IoT and AI, will enable smart manufacturing processes. This advancement will allow for predictive maintenance, real-time monitoring, and enhanced data analysis.

2. Increased Focus on Sustainability

With growing environmental concerns, manufacturers will continue to prioritize sustainable practices. This shift will drive the adoption of PET twin screw extruders capable of utilizing renewable materials and minimizing waste.

3. Advanced Materials Processing

Research into new materials and additives will expand the capabilities of twin screw extruders. Future developments may include the processing of bio-based PET and other innovative materials.

4. Enhanced Automation

Automation will play a significant role in improving production efficiency. Automated systems integrated with twin screw extruders will streamline operations, reduce labor costs, and enhance overall productivity.

Frequently Asked Questions

1. What is a PET twin screw extruder?

A PET twin screw extruder is a type of machinery used in the plastics industry that features two intermeshing screws for mixing, kneading, and extruding polyethylene terephthalate (PET) materials.

2. How does a twin screw extruder differ from a single screw extruder?

Twin screw extruders provide superior mixing and thermal management compared to single screw extruders, allowing for more efficient processing of various materials, including PET.

3. What are the benefits of using PET twin screw extruders?

The benefits include enhanced mixing, greater processing flexibility, improved energy efficiency, better thermal management, and reduced cycle times, leading to higher quality products.

4. Can PET twin screw extruders process recycled materials?

Yes, PET twin screw extruders are capable of processing recycled PET, making them an excellent choice for manufacturers looking to incorporate sustainable practices.

5. How do I choose the right PET twin screw extruder for my production line?

Consider factors such as production volume, material compatibility, customization options, and the availability of technical support and maintenance when selecting a PET twin screw extruder.

Conclusion

PET twin screw extruders represent a significant advancement in the field of plastics manufacturing, offering numerous benefits that can revolutionize production lines. Their ability to improve mixing, enhance efficiency, and support sustainability positions them as a vital component for manufacturers seeking to stay competitive in an evolving market. By investing in this technology, businesses can optimize their operations, produce high-quality products, and contribute to a more sustainable future in the plastics industry.

RELATED INFORMATION

How PET Sheet Extruders Revolutionize Plastic Processing Machinery

How PET Sheet Extruders Revolutionize Plastic Processing Machinery Table of Contents Introduction to PET Sheet Extruders Understanding Plastic Processing Machinery The Technology Behind PET Sheet Extruders Advantages of Using PET Sheet Extruders Sustainability in Plastic Manufacturing Applications of PET Sheets in Various Industries Future Trends in PET Sheet Extrusion

PET sheet extruder machines play a crucial role in the field of plastic processing, specifically in the production of polyethylene terephthalate (PET) sheets. These machines are designed to melt and extrude PET resin into sheets of varying thickness, which are then used in a variety of applications such as packaging, construction, and consumer goods. Understanding how these machines work and their