Understanding the PET Sheet Extruder: Key Features and Benefits

2025-11

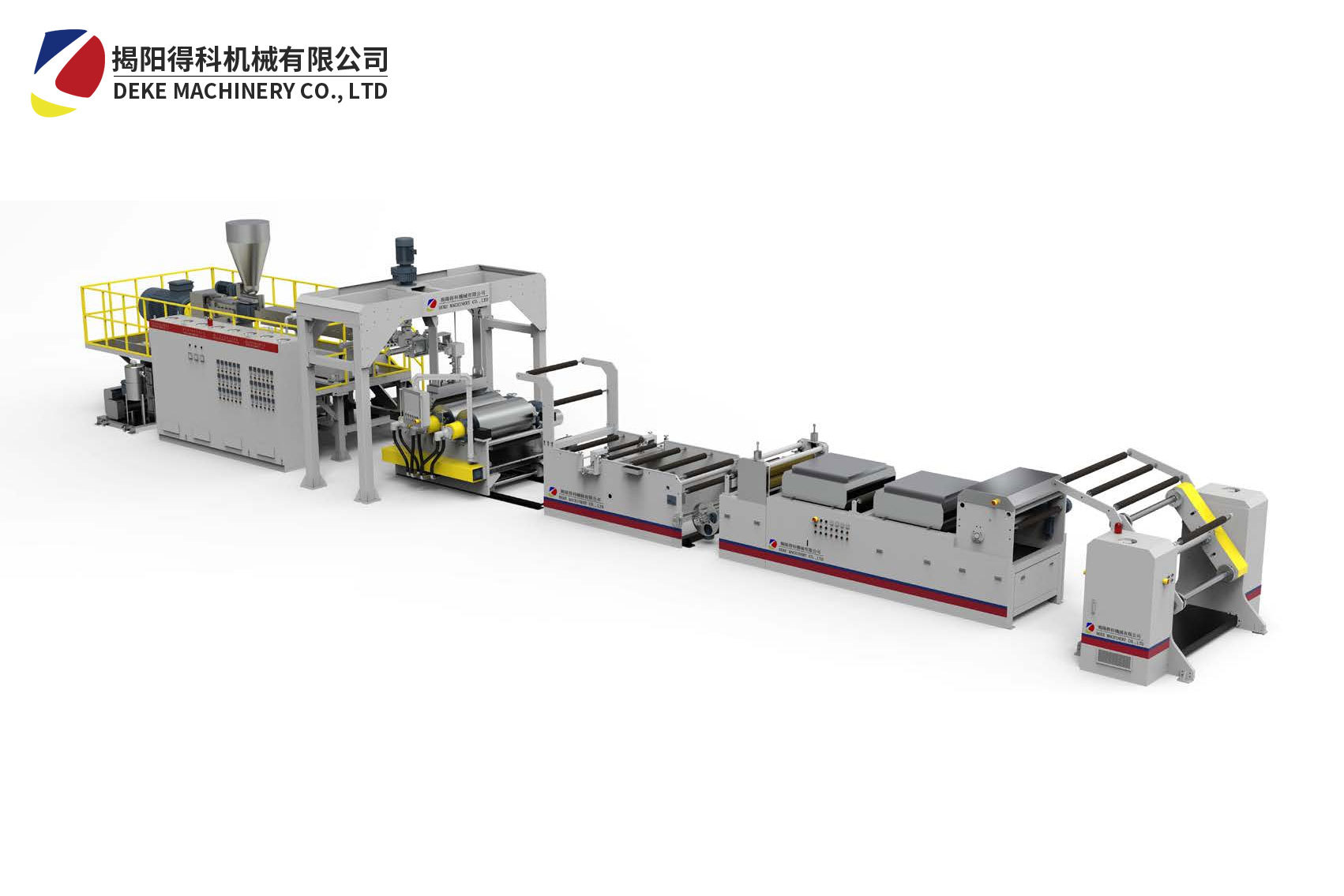

At the core of a PET sheet extruder is the extrusion process, which involves melting PET pellets and forcing the molten material through a die to form sheets of desired thickness and width. This process begins with the feeding of raw PET material into the extruder's hopper, where it is then transported through a heated screw. The screw not only melts the material but also ensures thorough mixing and homogenization, resulting in a consistent product.

One of the significant features of a PET sheet extruder is its ability to achieve high output rates while maintaining quality control. Advanced temperature control systems and precise screw design allow for efficient melting and shaping of the PET, reducing the risk of degradation and ensuring uniform thickness. Additionally, many PET sheet extruders are equipped with features such as adjustable die gaps and cooling systems, enabling manufacturers to customize their production according to specific requirements.

Another noteworthy advantage of using a PET sheet extruder is its energy efficiency. Modern extruders are designed with energy-saving technologies that reduce power consumption during the extrusion process. This not only lowers production costs but also contributes to a more sustainable manufacturing approach, which is increasingly important in today's eco-conscious market.

Moreover, PET sheets produced by these extruders boast excellent mechanical properties, making them suitable for a wide range of applications. They can be easily thermoformed, printed upon, and laminated, proving versatile for industries ranging from food and beverage packaging to electronic device enclosures.

In conclusion, investing in a PET sheet extruder can significantly enhance a manufacturer's capability to produce high-quality PET sheets efficiently and sustainably. By understanding the intricacies of this machinery, businesses can make informed decisions that support their production goals and environmental commitments. Whether you aim to improve product quality or streamline your operations, the PET sheet extruder stands out as an essential tool in the plastic processing industry.

RELATED INFORMATION

How PET Sheet Extruders Revolutionize Plastic Processing Machinery

How PET Sheet Extruders Revolutionize Plastic Processing Machinery Table of Contents Introduction to PET Sheet Extruders Understanding Plastic Processing Machinery The Technology Behind PET Sheet Extruders Advantages of Using PET Sheet Extruders Sustainability in Plastic Manufacturing Applications of PET Sheets in Various Industries Future Trends in PET Sheet Extrusion

PET sheet extruder machines play a crucial role in the field of plastic processing, specifically in the production of polyethylene terephthalate (PET) sheets. These machines are designed to melt and extrude PET resin into sheets of varying thickness, which are then used in a variety of applications such as packaging, construction, and consumer goods. Understanding how these machines work and their