How a PET Sheet Extruder Machine Significantly Enhances Production Efficiency

2025-11

How a PET Sheet Extruder Machine Significantly Enhances Production Efficiency

Table of Contents

- Introduction to PET Sheet Extruder Machines

- Understanding PET Sheets and Their Applications

- The Mechanism of PET Sheet Extrusion

- Key Benefits of Using PET Sheet Extruder Machines

- Innovative Features of Modern PET Sheet Extruders

- Applications of PET Sheets in Various Industries

- Maintenance Practices and Sustainability Considerations

- The Future of PET Sheet Extrusion Technology

- Frequently Asked Questions

- Conclusion

Introduction to PET Sheet Extruder Machines

In recent years, the demand for high-quality plastic materials has surged, making **PET sheet extruder machines** a cornerstone in the manufacturing industry. These machines play a crucial role in producing polyethylene terephthalate (PET) sheets, which are widely used in various applications, including packaging, textiles, and automotive components. Understanding how these machines operate and their impact on production efficiency is essential for manufacturers looking to optimize their processes and stay competitive.

Understanding PET Sheets and Their Applications

**PET sheets** are versatile plastic materials made from the polymerization of ethylene glycol and terephthalic acid. Renowned for their clarity, strength, and durability, these sheets are suitable for numerous applications:

- **Packaging:** PET sheets are extensively used in food and beverage packaging due to their excellent barrier properties and recyclability.

- **Textiles:** In the textile industry, PET is used for manufacturing synthetic fibers, offering durability and wrinkle resistance.

- **Automotive Components:** PET sheets are also utilized in automotive parts, showcasing their resilience and lightweight nature.

This versatility highlights the importance of efficient production processes, directly linking to how a PET sheet extruder machine can enhance productivity.

The Mechanism of PET Sheet Extrusion

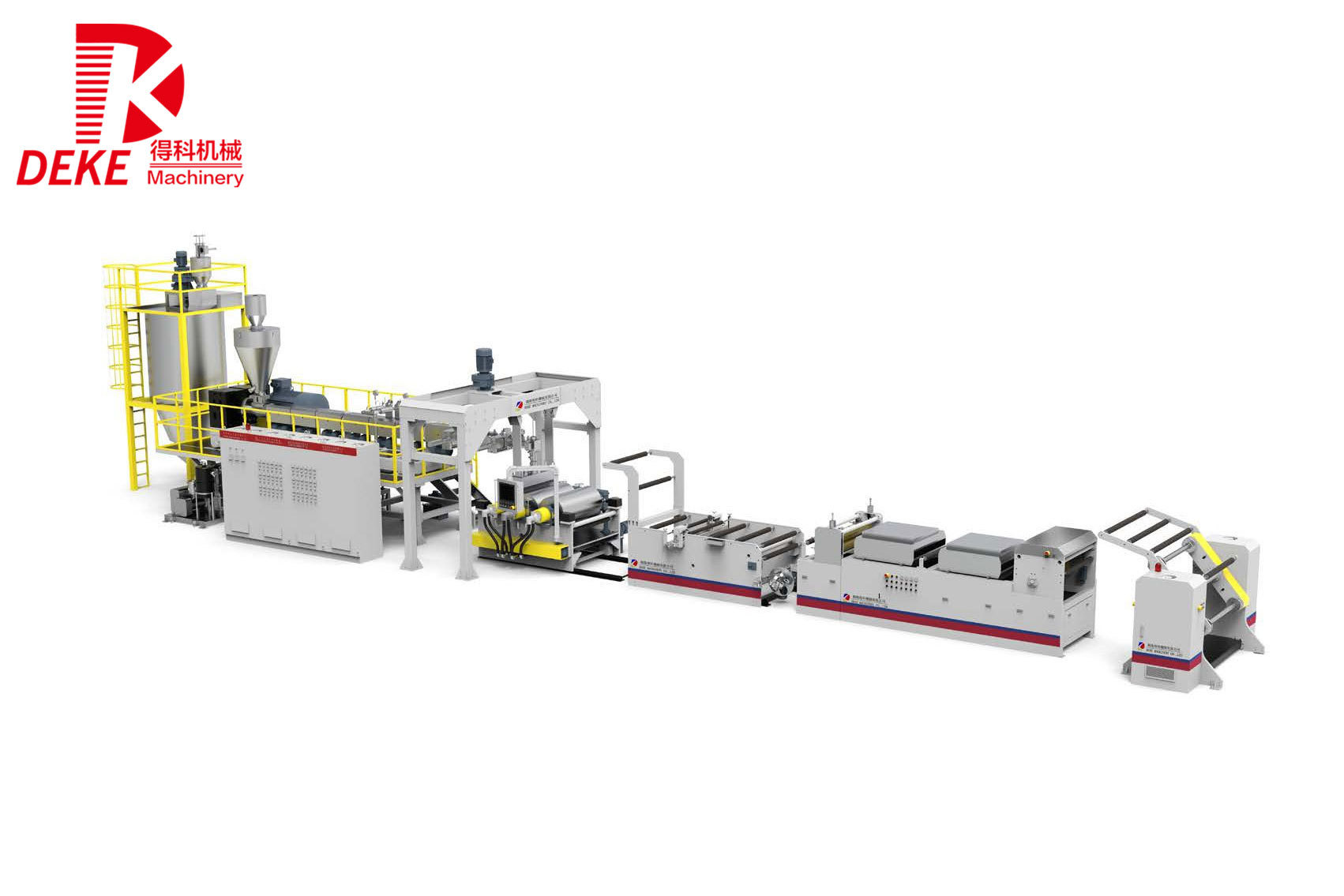

Understanding the operational mechanics of a PET sheet extruder is vital to appreciate its efficiency. The extrusion process involves several stages:

1. **Feeding:** Raw PET pellets are fed into the extruder's hopper.

2. **Melting:** The pellets are heated and melted within a barrel, where they are mixed thoroughly to achieve a uniform consistency.

3. **Extrusion:** The melted PET is forced through a flat die to form a continuous sheet.

4. **Cooling:** The extruded sheet is cooled, often using chill rolls, to stabilize its form.

5. **Cutting:** Finally, the cooled sheet is cut to the desired dimensions for subsequent applications.

This streamlined process enhances production efficiency by reducing waste and optimizing material usage.

Key Benefits of Using PET Sheet Extruder Machines

When considering investment in a PET sheet extruder machine, several key benefits come into play:

Enhanced Production Efficiency

**Production efficiency** is fundamentally improved through several mechanisms:

- **Higher Throughput:** Modern extruder machines can process large volumes of material quickly, allowing for higher output rates.

- **Consistent Quality:** Automated controls ensure uniformity in thickness and quality, reducing the need for rework.

- **Reduced Downtime:** Advanced technology minimizes breakdowns, keeping production lines running efficiently.

Cost-Effectiveness

Investing in a PET sheet extruder machine can lead to significant cost savings:

- **Material Savings:** Efficient use of raw materials reduces waste, lowering overall production costs.

- **Labor Efficiency:** Automation decreases the need for manual labor, leading to lower labor costs and higher efficiency.

- **Energy Efficiency:** Modern machines are designed to consume less energy, further contributing to cost savings.

Quality Improvement

**Quality is paramount** in manufacturing, and PET sheet extruders excel in this area:

- **Enhanced Product Quality:** The precise control over extrusion parameters ensures high-quality output.

- **Customization Capabilities:** Manufacturers can tailor the properties of the PET sheets to meet specific requirements, enhancing product value.

Innovative Features of Modern PET Sheet Extruders

Recent advancements in PET sheet extruder technology have introduced innovative features that further improve production efficiency:

- **Real-Time Monitoring:** Advanced sensors and software facilitate real-time monitoring of production parameters, allowing for immediate adjustments.

- **Energy Recovery Systems:** Some machines are now equipped with systems that recover and reuse energy, enhancing sustainability.

- **High-Performance Materials:** The use of advanced materials in the construction of extruders improves durability and reduces maintenance needs.

Applications of PET Sheets in Various Industries

The applications of PET sheets are extensive and varied, including:

- **Food Packaging:** The food industry relies on PET sheets for containers and trays, ensuring safety and freshness.

- **Medical Devices:** In the healthcare sector, PET sheets are used for packaging medical instruments and devices, where sterility is crucial.

- **Electronics:** PET sheets serve as protective covers for electronic devices, providing durability and clarity.

The versatility of PET sheets underscores the importance of efficient production processes facilitated by extruder machines.

Maintenance Practices and Sustainability Considerations

To maximize the efficiency and longevity of PET sheet extruder machines, regular maintenance is essential:

- **Routine Inspections:** Regular checks of the machine's components can prevent unexpected breakdowns and maintain performance.

- **Cleaning Protocols:** Implementing cleaning protocols ensures that the equipment operates efficiently and produces high-quality sheets.

- **Sustainability Practices:** Many manufacturers are adopting sustainable practices, such as recycling scrap PET and minimizing energy consumption.

The Future of PET Sheet Extrusion Technology

Looking ahead, the future of PET sheet extrusion technology appears promising:

- **Emerging Technologies:** Innovations such as 3D printing and biodegradable materials are likely to influence the development of PET sheet applications.

- **Industry 4.0 Integration:** The integration of IoT (Internet of Things) technologies will pave the way for smarter machines capable of predictive maintenance and automated quality control.

- **Sustainability Focus:** As environmental concerns grow, manufacturers are likely to prioritize sustainable production practices, leading to an evolution in PET sheet production methods.

Frequently Asked Questions

1. What is a PET sheet extruder machine?

A PET sheet extruder machine is specialized equipment used to produce polyethylene terephthalate (PET) sheets through an extrusion process, offering high efficiency and quality.

2. How does a PET sheet extruder improve production efficiency?

It enhances production efficiency by increasing throughput, ensuring consistent quality, and reducing material waste and downtime.

3. What industries benefit from PET sheet production?

Industries such as food packaging, healthcare, electronics, and textiles significantly benefit from PET sheet production due to its versatility.

4. What maintenance is required for PET sheet extruder machines?

Routine inspections, cleaning protocols, and timely repairs are essential for maintaining optimal performance and longevity of PET sheet extruders.

5. How can I ensure the quality of PET sheets produced?

Implementing automated controls and real-time monitoring systems can help maintain consistent quality throughout the production process.

Conclusion

The **PET sheet extruder machine** represents a leap forward in manufacturing efficiency, offering numerous benefits that can transform production processes. By understanding the mechanisms, advantages, and innovations associated with this technology, manufacturers can leverage it to enhance productivity, reduce costs, and improve product quality. As the industry evolves, staying informed about trends and practices will be crucial for maintaining a competitive edge. Embracing these advancements will not only improve production efficiency but also contribute to a more sustainable manufacturing landscape.

RELATED INFORMATION

How PET Sheet Extruders Revolutionize Plastic Processing Machinery

How PET Sheet Extruders Revolutionize Plastic Processing Machinery Table of Contents Introduction to PET Sheet Extruders Understanding Plastic Processing Machinery The Technology Behind PET Sheet Extruders Advantages of Using PET Sheet Extruders Sustainability in Plastic Manufacturing Applications of PET Sheets in Various Industries Future Trends in PET Sheet Extrusion

PET sheet extruder machines play a crucial role in the field of plastic processing, specifically in the production of polyethylene terephthalate (PET) sheets. These machines are designed to melt and extrude PET resin into sheets of varying thickness, which are then used in a variety of applications such as packaging, construction, and consumer goods. Understanding how these machines work and their