The Science Behind Twin Screw Extruder Performance in Plastic Processing

2025-11

The Science Behind Twin Screw Extruder Performance in Plastic Processing

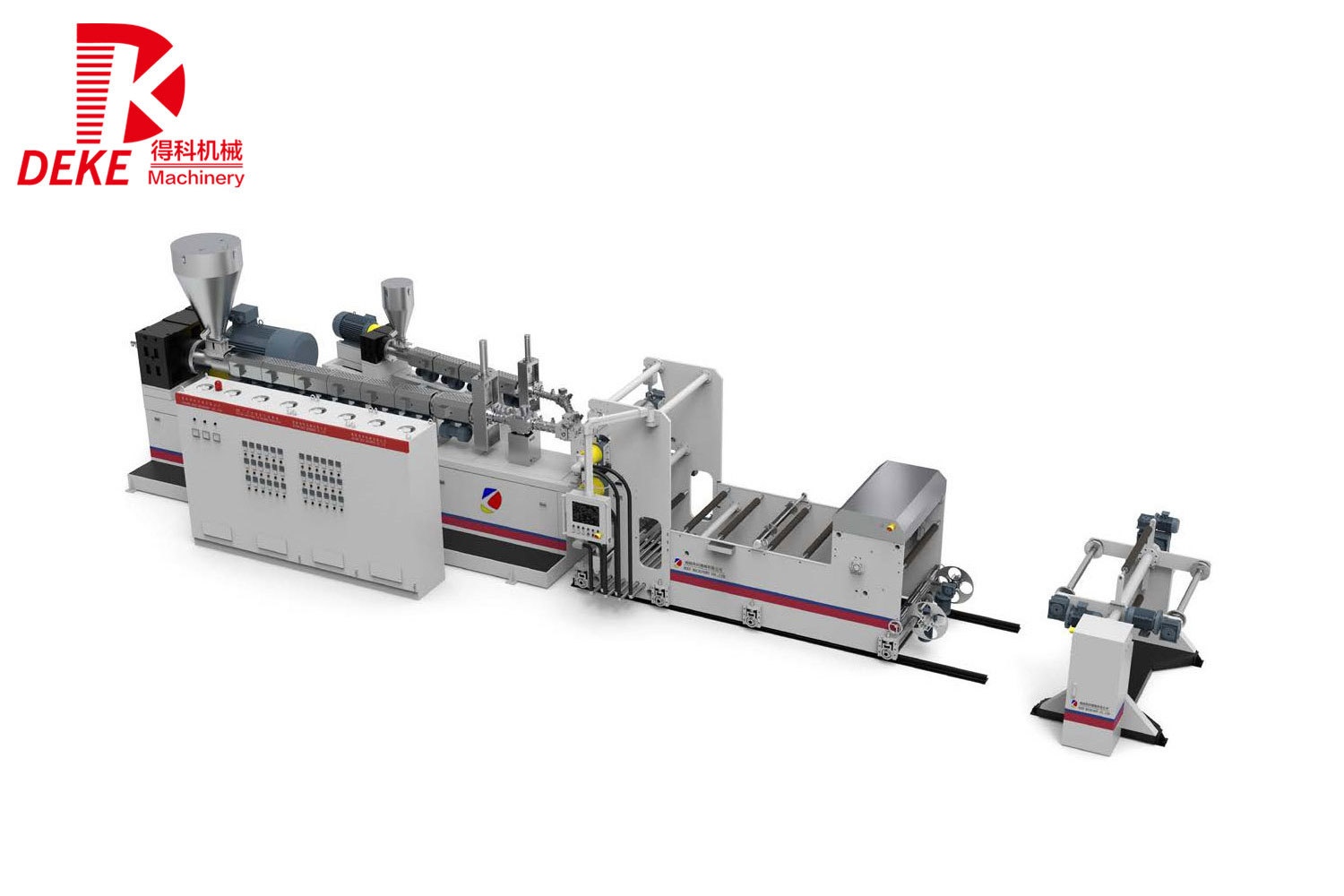

In the realm of plastic processing, twin screw extruders play a pivotal role in the manufacturing of a wide variety of plastic products. Their intricate design and operational mechanics make them indispensable in achieving high-performance plastic processing. This article will delve deep into the science behind twin screw extruder performance, examining the factors that influence their efficiency and effectiveness in transforming raw materials into finished products.

Table of Contents

- Introduction to Twin Screw Extruders

- Working Principle of Twin Screw Extruders

- Key Components of Twin Screw Extruders

- Performance Factors Influencing Twin Screw Extruder Efficiency

- Applications of Twin Screw Extruders in Plastic Processing

- Advantages of Twin Screw Extruders Over Single Screw Extruders

- Maintenance and Troubleshooting for Optimal Performance

- Future Trends in Twin Screw Extrusion Technology

- Conclusion

- FAQs

Introduction to Twin Screw Extruders

Twin screw extruders are sophisticated machines designed to melt, mix, and shape thermoplastics and other materials. Their unique configuration, featuring two intermeshing screws, allows for enhanced mixing and homogenization of materials during processing. This technology is crucial for producing a range of plastic products, from simple profiles to complex composite materials.

Working Principle of Twin Screw Extruders

The fundamental operation of a twin screw extruder involves the continuous feeding of raw materials into the extruder's hopper. As the screws rotate, they convey the materials through various zones of the extruder, each carefully engineered to perform specific functions such as melting, mixing, and shaping. The screws' intermeshing design ensures that materials are thoroughly mixed and heated, resulting in a homogeneous melt that can be formed into desired shapes.

Feeding Zone

The feeding zone is where the initial material is introduced. The design of this zone is critical, as it determines how effectively the materials are fed into the extruder and influences the overall throughput.

Melting Zone

In the melting zone, the temperature is carefully regulated to ensure that the materials reach their melting point without degrading. This involves a combination of mechanical shear and thermal energy, which is crucial for achieving optimal material properties.

Mixing Zone

The mixing zone is where the magic happens. The design of the screws, the temperature, and the material flow rates all contribute to the effectiveness of the mixing process. This area may include various elements such as kneading blocks and mixing sections to achieve the desired material consistency.

Extrusion and Cooling Zone

Finally, the material is shaped and cooled in the extrusion zone. This is where the melted plastic is forced through a die to create specific profiles, followed by rapid cooling to solidify the product.

Key Components of Twin Screw Extruders

Understanding the components of twin screw extruders is essential for optimizing their performance. Key elements include:

Screws

The screws are the heart of the extruder, where the primary processing occurs. Their design, including pitch, depth, and length, dictates the flow characteristics and mixing efficiency.

Barrel

The barrel houses the screws and is equipped with heating and cooling capabilities to control the processing temperature. Its design can significantly affect the material's flow and processing efficiency.

Drive System

The drive system provides the necessary power to rotate the screws. The choice of motor and gearbox can impact the torque and speed, influencing the extruder's overall performance.

Die

The die shapes the melted plastic into the desired form. Its design varies based on the end-product specifications and directly affects the product's quality.

Performance Factors Influencing Twin Screw Extruder Efficiency

Several factors can influence the performance of twin screw extruders, including:

Material Properties

The characteristics of the materials being processed, such as viscosity, thermal stability, and flow behavior, play a significant role in extruder performance. Understanding these properties can help in adjusting processing parameters for optimal results.

Processing Conditions

Parameters such as temperature, pressure, and screw speed need to be carefully controlled. Variations can lead to inconsistencies in the product and affect overall efficiency.

Design Configuration

The configuration of the screws and barrel can be tailored to specific applications, which can enhance mixing and processing efficiency. Custom designs are often necessary for specialized applications.

Maintenance Practices

Regular maintenance is crucial for ensuring optimal performance. Wear and tear on screws and barrels can lead to reduced efficiency and product quality.

Applications of Twin Screw Extruders in Plastic Processing

Twin screw extruders are versatile machines used across various sectors within the plastic industry. Key applications include:

Compounding

The compounding process involves mixing various additives with the base polymer to enhance properties such as color, strength, and durability. Twin screw extruders provide superior mixing capabilities for this application.

Recycling

In the recycling industry, twin screw extruders are used to process recycled plastics. They help ensure that the recycled material is adequately melted and mixed, allowing for high-quality end products.

Filament Production

In 3D printing, twin screw extruders are utilized to produce filaments. Their ability to control temperature and mixing is essential for creating high-quality printing materials.

Food and Pharmaceutical Applications

Twin screw extruders are also used in the food and pharmaceutical industries for producing granular products and pharmaceuticals, respectively. Their ability to handle sensitive materials makes them ideal for these applications.

Advantages of Twin Screw Extruders Over Single Screw Extruders

When comparing twin screw extruders to single screw extruders, several advantages emerge:

Enhanced Mixing and Homogenization

The intermeshing design of twin screws allows for superior mixing and homogenization compared to single screws, resulting in more consistent product quality.

Greater Process Flexibility

Twin screw extruders can accommodate a wider range of materials and processing conditions, making them more versatile for various applications.

Improved Efficiency

With better control over processing parameters, twin screw extruders often demonstrate higher efficiency and throughput, ultimately leading to reduced production costs.

Better Material Handling

The design of twin screw extruders allows for better handling of materials with varying viscosities, making them suitable for a broader spectrum of products.

Maintenance and Troubleshooting for Optimal Performance

To ensure twin screw extruders function at peak performance, regular maintenance is essential. Key practices include:

Regular Inspections

Conducting routine inspections of screws, barrels, and other critical components can help detect wear and prevent unexpected breakdowns.

Cleaning Procedures

Implementing effective cleaning procedures after each production run minimizes contamination and ensures the quality of subsequent batches.

Calibration and Testing

Regular calibration of temperature and pressure settings is crucial for maintaining consistent product quality. Testing material samples can provide insights into the performance of the extruder.

Future Trends in Twin Screw Extrusion Technology

The future of twin screw extrusion technology looks promising, with several trends emerging:

Increased Automation

Automation is expected to enhance the efficiency and precision of twin screw extrusion processes, allowing for real-time monitoring and adjustments.

Advanced Material Science

As new materials are developed, twin screw extruders will adapt to accommodate these innovations, expanding their applications across various industries.

Sustainability Practices

The push for sustainable manufacturing practices will drive the development of twin screw extruders that can efficiently process recycled materials and reduce waste.

Conclusion

Twin screw extruders are a cornerstone of modern plastic processing, offering unparalleled efficiency, versatility, and performance. Understanding the science behind their operation and the factors that influence their efficiency is essential for anyone involved in the plastic manufacturing industry. As technology advances and new materials are introduced, twin screw extruders will continue to evolve, maintaining their critical role in producing high-quality plastic products.

FAQs

1. What materials can be processed with twin screw extruders?

Twin screw extruders can process a wide variety of thermoplastics, thermosets, and composite materials, making them versatile for many applications.

2. How do twin screw extruders enhance mixing efficiency?

The intermeshing design of the screws allows for comprehensive contact between materials, leading to improved mixing and homogenization.

3. What is the typical maintenance schedule for twin screw extruders?

Maintenance should be conducted regularly, including daily checks for wear, cleaning between production runs, and thorough inspections at scheduled intervals.

4. How do I choose the right twin screw extruder for my application?

Choosing the right extruder depends on factors such as the type of materials you will be processing, desired throughput, and specific product requirements.

5. Can twin screw extruders be used for recycling plastic?

Yes, twin screw extruders are highly effective for recycling plastic, enabling the production of quality recycled materials through careful processing.

RELATED INFORMATION

Why Choose Conical Twin Screw for Your Next Extrusion Project?

Why Choose Conical Twin Screw for Your Next Extrusion Project? Understanding Extrusion Technology In the realm of **plastic processing**, extrusion is an essential manufacturing technique that transforms raw plastic materials into usable products. The **extrusion process** involves forcing molten plastic through a die to create continuous shapes like sheets, films, and profiles. With advancements

Understanding the Advantages of Counter Rotating Twin Screw Extruders for Plastic Processing

Counter rotating twin screw extruders are pivotal in the plastic processing industry, recognized for their versatility and efficiency. Unlike single screw extruders, twin screw extruders feature two intermeshing screws that rotate in opposite directions. This design allows for enhanced material handling and processing capabilities, making them suitable for a wide array of applications. One of the