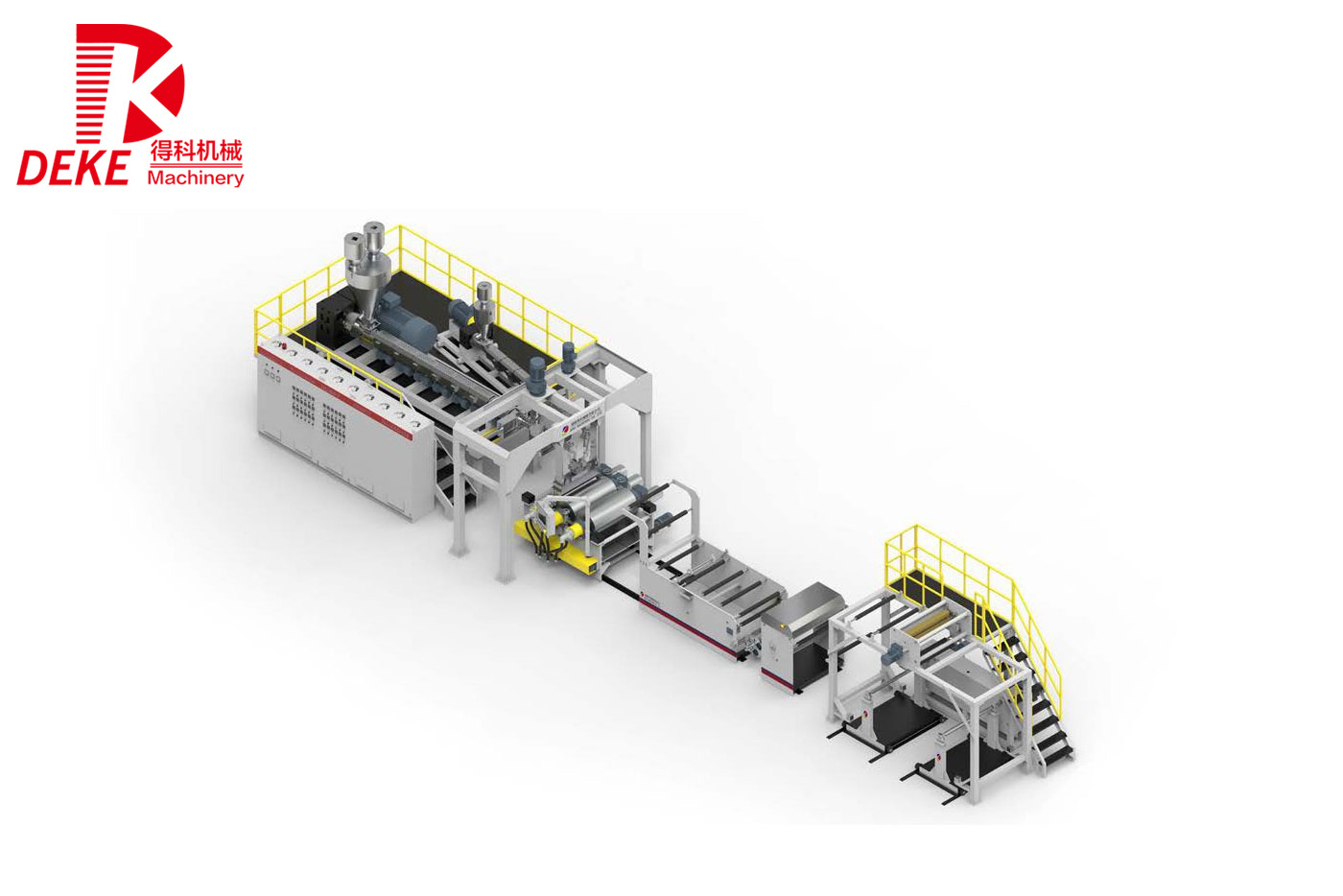

Understanding the Benefits and Applications of Counter Rotating Twin Screw Extruders

2025-11

One of the primary benefits of counter rotating twin screw extruders is their superior mixing capabilities. The opposing motion of the screws facilitates a more uniform distribution of additives, colorants, and other materials within the base polymer. This is particularly important in applications requiring high-quality end products, such as engineered plastics and thermoplastics, where consistent material properties are crucial. The ability to achieve uniformity in mixing can significantly improve the performance characteristics of the final product.

Additionally, the design of counter rotating twin screw extruders allows for better control over the processing environment. The individual screws can be engineered to create different flow patterns and shear rates, which is vital for processing various types of polymers. This flexibility enables manufacturers to tailor the extrusion process to specific requirements, leading to optimized material formulations and reduced waste.

Another significant advantage of these extruders is their ability to handle a wide range of materials. From thermoplastics to thermosets, the counter rotating twin screw extruder can accommodate various formulations, including filled and reinforced materials. This versatility makes them an attractive choice for manufacturers looking to expand their product offerings without the need for extensive machinery investments.

Moreover, counter rotating twin screw extruders are particularly effective in the production of high-viscosity materials and compounds. Their design can effectively manage the challenges associated with processing thicker materials, ensuring a smooth flow through the extruder and reducing the risk of blockages or inconsistencies.

The maintenance and operational efficiency of counter rotating twin screw extruders further enhance their appeal. Many modern models are designed with user-friendly features that simplify cleaning and maintenance processes, ensuring minimal downtime and improved productivity.

In summary, counter rotating twin screw extruders stand out due to their innovative design and operational benefits. By enabling superior mixing, providing control over processing, and accommodating a broad spectrum of materials, they play a crucial role in the advancement of plastic processing technology. For manufacturers aiming to achieve high-quality products and optimized processing conditions, investing in counter rotating twin screw extruders can be a pivotal step forward in their production capabilities.

Previous Page:

RELATED INFORMATION

Why Choose Conical Twin Screw for Your Next Extrusion Project?

Why Choose Conical Twin Screw for Your Next Extrusion Project? Understanding Extrusion Technology In the realm of **plastic processing**, extrusion is an essential manufacturing technique that transforms raw plastic materials into usable products. The **extrusion process** involves forcing molten plastic through a die to create continuous shapes like sheets, films, and profiles. With advancements

Understanding the Advantages of Counter Rotating Twin Screw Extruders for Plastic Processing

Counter rotating twin screw extruders are pivotal in the plastic processing industry, recognized for their versatility and efficiency. Unlike single screw extruders, twin screw extruders feature two intermeshing screws that rotate in opposite directions. This design allows for enhanced material handling and processing capabilities, making them suitable for a wide array of applications. One of the