From Raw Material to Product: The Crucial Role of PET Single Screw Extruders in Manufacturing

2025-11

From Raw Material to Product: The Crucial Role of PET Single Screw Extruders in Manufacturing

Table of Contents

- 1. Introduction to PET and Its Importance in Manufacturing

- 2. Understanding the Extrusion Process

- 3. What is PET? A Deep Dive into Polyethylene Terephthalate

- 4. Single Screw Extruders: The Heart of PET Processing

- 5. Advantages of Using Single Screw Extruders for PET

- 6. Applications of PET Extrusion in Various Industries

- 7. The Future of PET Extrusion Technology

- 8. Conclusion

- 9. FAQs About PET Single Screw Extrusion

1. Introduction to PET and Its Importance in Manufacturing

The manufacturing industry relies heavily on polymers, with polyethylene terephthalate (PET) being one of the most widely used plastics. PET is known for its excellent strength-to-weight ratio, barrier properties, and resistance to moisture and chemicals. As the demand for sustainable materials increases, PET has emerged as a frontrunner in recycling initiatives, making it a vital component in various sectors, including packaging, textiles, and automotive components.

2. Understanding the Extrusion Process

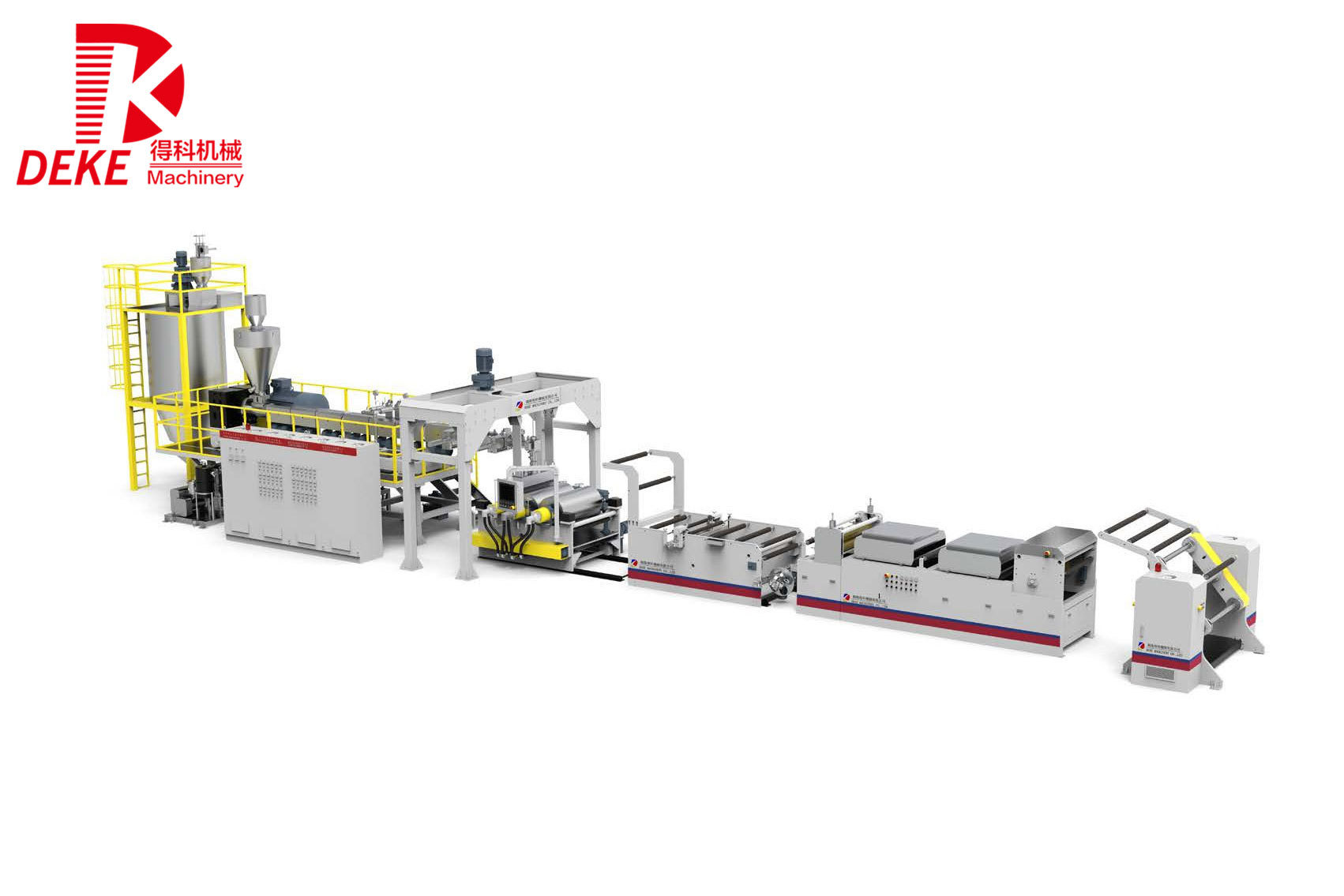

Extrusion is a manufacturing process that transforms raw materials into semi-finished or finished products. This continuous process involves forcing material through a shaped die to create long shapes or sheets. In the case of PET, single screw extruders play a pivotal role in converting solid PET pellets into usable forms. Understanding the intricacies of this process can illuminate the advantages and challenges faced by manufacturers.

3. What is PET? A Deep Dive into Polyethylene Terephthalate

Polyethylene terephthalate, commonly referred to as PET, is a thermoplastic polymer that is part of the polyester family. This versatile material is produced through a polymerization process involving terephthalic acid and ethylene glycol. Its characteristics, such as durability, lightweight nature, and recyclability, make it suitable for a wide range of applications. From beverage bottles to food containers, PET is integral to modern packaging solutions.

4. Single Screw Extruders: The Heart of PET Processing

Single screw extruders are essential in the manufacturing of PET products. The mechanism involves a single rotating screw within a heated barrel, which facilitates the melting and mixing of PET pellets. The process can be broken down into several stages, including feeding, melting, mixing, and cooling. Each of these stages is crucial for producing high-quality PET products.

4.1 The Feeding Stage

In the feeding stage, PET pellets are introduced into the extruder. A hopper regulates the flow of material into the barrel, ensuring a consistent feed rate. This stage is critical as it influences the overall production efficiency and quality.

4.2 The Melting Stage

Once the pellets enter the heated barrel, they begin to melt. The temperature is carefully controlled to activate the rheological properties of the PET, allowing for proper flow and processing. Achieving the ideal melting temperature is vital to prevent degradation of the material.

4.3 The Mixing Stage

During mixing, additives may be incorporated to enhance the properties of the PET. This could include colorants, stabilizers, or other functional additives. The single screw design ensures thorough mixing, which is essential for achieving uniform product characteristics.

4.4 The Cooling Stage

After the PET has been extruded through the die, it enters the cooling stage. Rapid cooling is essential to solidify the material into the desired shape, ensuring dimensional accuracy and mechanical strength.

5. Advantages of Using Single Screw Extruders for PET

Utilizing single screw extruders offers numerous benefits for PET processing. These advantages include:

5.1 Cost-Effectiveness

Single screw extruders are generally more affordable than their twin-screw counterparts. This cost-effectiveness makes them an attractive option for many manufacturers, particularly those producing lower volumes of PET products.

5.2 Simplicity and Reliability

The design of single screw extruders is straightforward, resulting in fewer mechanical components. This simplicity contributes to higher reliability and easier maintenance, reducing downtime and associated costs.

5.3 Flexibility in Production

Single screw extruders can easily accommodate a variety of PET formulations and additives. This flexibility allows manufacturers to respond quickly to changing market demands and product specifications.

6. Applications of PET Extrusion in Various Industries

The applications of PET extrusion are vast and diverse. Some notable uses include:

6.1 Packaging Industry

PET is extensively used in the packaging industry, particularly for beverage bottles, food containers, and packaging films. Its ability to provide excellent moisture and oxygen barriers makes it ideal for preserving product freshness.

6.2 Textile Industry

In textiles, PET is employed in the production of fibers for clothing and upholstery. Its durability and resistance to wrinkles and shrinking make it a preferred choice for many textile applications.

6.3 Automotive Industry

In the automotive sector, PET is utilized for manufacturing various components, such as interior trim and exterior parts. Its lightweight nature contributes to fuel efficiency and reduces overall vehicle weight.

7. The Future of PET Extrusion Technology

As the demand for sustainable materials continues to grow, the future of PET extrusion technology looks promising. Innovations in recycling technologies, such as chemical recycling, are paving the way for more sustainable PET processing. Additionally, advancements in extrusion machinery are enhancing production efficiency and product quality.

8. Conclusion

PET single screw extruders play a critical role in the transition of raw materials to finished products. Their efficiency, reliability, and adaptability make them indispensable in various industries. As technology continues to evolve, the potential for PET extrusion will only expand, driving innovation and sustainability in manufacturing.

9. FAQs About PET Single Screw Extrusion

1. What is the primary function of a single screw extruder?

The primary function of a single screw extruder is to melt, mix, and shape thermoplastic materials, such as PET, into usable forms through a continuous process.

2. How does PET compare to other plastics in terms of recyclability?

PET is one of the most recyclable plastics available, making it a preferred choice for environmentally conscious manufacturers. It can be recycled multiple times without significant degradation of its properties.

3. What are the typical processing temperatures for PET in extrusion?

The processing temperatures for PET can range from 200°C to 280°C, depending on the specific formulation and desired properties.

4. Can single screw extruders handle different types of polymer materials?

Yes, single screw extruders can process various polymer materials, although adjustments may be required in terms of temperature, feed rate, and screw design for optimal performance.

5. What are some common challenges faced during PET extrusion?

Common challenges include material degradation, inconsistent melting, and the need for precise temperature control. Addressing these issues is crucial for maintaining product quality and production efficiency.

RELATED INFORMATION

How PET Sheet Extruders Revolutionize Plastic Processing Machinery

How PET Sheet Extruders Revolutionize Plastic Processing Machinery Table of Contents Introduction to PET Sheet Extruders Understanding Plastic Processing Machinery The Technology Behind PET Sheet Extruders Advantages of Using PET Sheet Extruders Sustainability in Plastic Manufacturing Applications of PET Sheets in Various Industries Future Trends in PET Sheet Extrusion

PET sheet extruder machines play a crucial role in the field of plastic processing, specifically in the production of polyethylene terephthalate (PET) sheets. These machines are designed to melt and extrude PET resin into sheets of varying thickness, which are then used in a variety of applications such as packaging, construction, and consumer goods. Understanding how these machines work and their