Understanding PET Sheet Extruders: Key Insights for Efficient Plastic Processing

2025-11

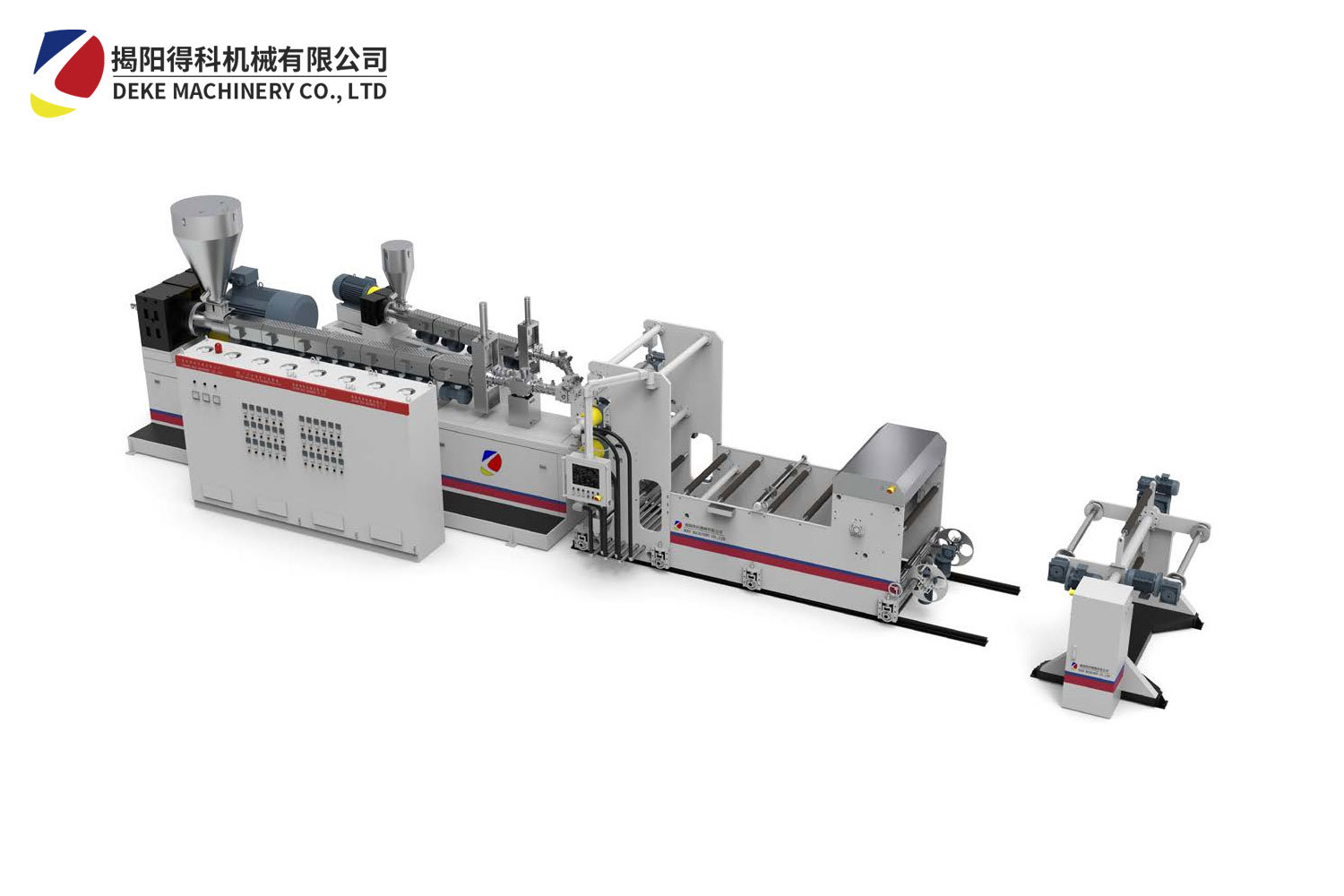

The fundamental operation of a PET sheet extruder involves melting PET resin pellets and forcing the molten material through a die to create a continuous sheet. This process requires precise temperature control, as the melting point of PET is relatively high. Maintaining optimal processing temperatures is crucial to prevent degradation of the material, ensuring that the final product retains its desirable properties.

One of the key advantages of using a PET sheet extruder is its ability to create sheets with a uniform thickness and smooth surface finish. This uniformity is essential in applications where visual aesthetics and structural integrity are paramount. Moreover, PET sheets produced via extrusion can be easily thermoformed into various shapes, making them versatile for a wide range of end-uses.

When selecting a PET sheet extruder, several technical specifications should be considered. The screw design plays a pivotal role in determining the efficiency of material melting and dispersion. A well-designed screw enhances the quality of the extrudate by ensuring consistent mixing and shear, which is vital for achieving optimal material properties. Additionally, the type of die used can influence the sheet's thickness and surface characteristics; therefore, careful selection is necessary based on the intended application.

The importance of process optimization in PET sheet extrusion cannot be overstated. Factors such as feed rate, cooling methods, and take-off speeds need to be meticulously managed for optimal production. Advanced control systems can facilitate real-time monitoring and adjustments, allowing manufacturers to enhance productivity and reduce waste.

Lastly, sustainability is becoming a crucial factor in the plastic processing industry. PET, being recyclable, presents an opportunity for manufacturers to embrace eco-friendly practices. Utilizing recycled PET in the extrusion process can lead to significant waste reduction and contribute positively to the environment.

In conclusion, understanding the nuances of PET sheet extruders can empower manufacturers to improve production efficiency, product quality, and sustainability. By focusing on key operational parameters and utilizing advanced technology, businesses can remain competitive in the evolving landscape of plastic processing.

Previous Page:

RELATED INFORMATION

How PET Sheet Extruders Revolutionize Plastic Processing Machinery

How PET Sheet Extruders Revolutionize Plastic Processing Machinery Table of Contents Introduction to PET Sheet Extruders Understanding Plastic Processing Machinery The Technology Behind PET Sheet Extruders Advantages of Using PET Sheet Extruders Sustainability in Plastic Manufacturing Applications of PET Sheets in Various Industries Future Trends in PET Sheet Extrusion

PET sheet extruder machines play a crucial role in the field of plastic processing, specifically in the production of polyethylene terephthalate (PET) sheets. These machines are designed to melt and extrude PET resin into sheets of varying thickness, which are then used in a variety of applications such as packaging, construction, and consumer goods. Understanding how these machines work and their