Understanding the Mechanics of PET Single Screw Extruders: A Comprehensive Guide

2025-12

Understanding the Mechanics of PET Single Screw Extruders

Introduction to PET Single Screw Extruders

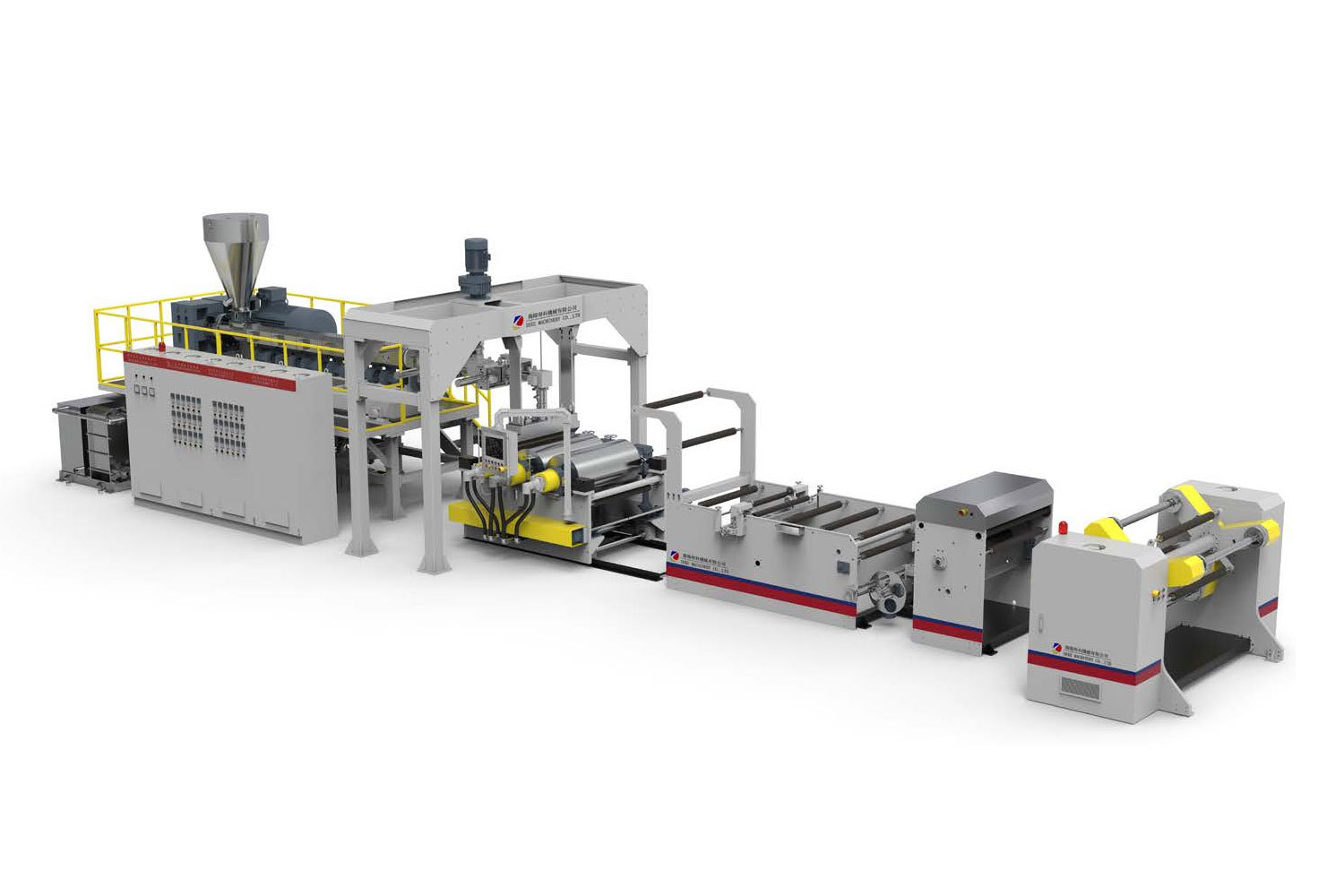

PET single screw extruders are pivotal in the plastic manufacturing industry. These machines play a crucial role in converting raw PET pellets into a variety of products, ranging from bottles to fibers. Understanding their mechanics is essential for maximizing efficiency and output quality in manufacturing processes.

What is a PET Single Screw Extruder?

A PET single screw extruder is a type of machinery designed to melt and shape plastic materials, specifically PET. The single screw configuration allows for continuous processing, making it ideal for high-volume applications. These machines utilize a rotating screw housed within a heated barrel to melt and convey the plastic material.

The Role of PET in Manufacturing

Polyethylene Terephthalate, commonly known as PET, is a thermoplastic polymer widely used due to its excellent mechanical properties and versatility. It can be found in numerous applications, including beverage containers, food packaging, and textile fibers. Understanding the functionalities of PET in the extrusion process is vital for manufacturers seeking to enhance product quality.

Key Components of a PET Single Screw Extruder

To grasp the mechanics of PET single screw extruders fully, one must understand their main components:

1. The Screw

The heart of the extruder, the screw, is designed to transport, melt, and mix the PET pellets. Its geometry, including flight depth and pitch, significantly influences the material's flow and heating.

2. The Barrel

The barrel encases the screw and provides the necessary heating zones to melt the PET. Typically, it is equipped with temperature control units to maintain optimal processing temperatures throughout the extrusion process.

3. The Hopper

The hopper feeds the PET pellets into the extruder. Its design ensures a steady and consistent supply of materials to the screw for uninterrupted operation.

4. The Die

The die shapes the melted PET into the desired form, whether sheets, films, or other profiles. The die design is critical as it directly impacts the final product's dimensions and characteristics.

5. The Cooling System

After shaping, a cooling system is integrated to solidify the PET product, ensuring it maintains its shape and structural integrity.

The Extrusion Process of PET Single Screw Extruders

Understanding the steps involved in the extrusion process can enhance operational efficiency:

1. Feeding the Material

Initially, PET pellets are gravity-fed from the hopper into the screw channel. The design of the hopper is crucial for preventing bridging and ensuring a smooth flow of materials.

2. Melting and Mixing

As the screw rotates, the PET pellets are subjected to increasing temperatures due to the heated barrel. This heat melts the pellets, while the screw's design promotes thorough mixing, enhancing homogeneity in the melt.

3. Conveying the Melt

The melted PET is then conveyed towards the die through the screw's forward section. The pressure built up in this phase is essential for pushing the melt through the die.

4. Shaping the Product

Once the melt reaches the die, it is forced through the die openings, where it takes on the desired shape. This step is crucial, as the die design dictates the final product's thickness and width.

5. Cooling and Solidifying

After exiting the die, the newly formed PET product is subjected to a cooling process, solidifying its shape. This can be achieved through air cooling, water baths, or other cooling methods depending on the specific application.

Advantages of Using PET Single Screw Extruders

Implementing PET single screw extruders offers numerous advantages for manufacturers, including:

1. High Throughput Rates

Single screw extruders are designed for continuous operation, allowing for high production rates, which is crucial in meeting consumer demands.

2. Versatility in Product Design

The ability to customize die designs enables manufacturers to produce a wide range of products, making PET single screw extruders versatile in application.

3. Energy Efficiency

Modern PET single screw extruders are designed for energy efficiency, reducing operational costs while maintaining high performance.

4. Enhanced Product Quality

With precise temperature control and effective mixing capabilities, these extruders ensure high-quality outputs with minimal defects.

5. Cost-Effective Maintenance

The simplicity of the design allows for easier maintenance, reducing downtime and associated costs, which is essential for maximizing productivity.

Applications of PET Single Screw Extruders

PET single screw extruders find wide-ranging applications in various industries:

1. Beverage Industry

They produce containers and bottles for soft drinks, water, and other beverages, making them essential in the food and beverage sector.

2. Textile Manufacturing

In the textile industry, PET is used to create fibers and yarns, benefiting from the high tensile strength and durability of the polymer.

3. Packaging Solutions

PET single screw extruders are widely utilized in the production of packaging films and sheets, enhancing product protection and shelf life.

4. Automotive Parts

In the automotive sector, PET is used to manufacture components that require lightweight and strong materials, contributing to fuel efficiency.

5. Consumer Goods

From household products to electronics, PET is a preferred choice owing to its versatility and recyclability.

Maintenance Tips for PET Single Screw Extruders

To ensure longevity and optimal performance of PET single screw extruders, regular maintenance is essential:

1. Regular Inspections

Conduct routine inspections to identify wear and tear, particularly on the screw and barrel. Early detection can prevent costly repairs.

2. Cleaning Protocols

Establish a cleaning protocol to remove residual materials and contaminants that may affect subsequent production runs.

3. Lubrication

Ensure all moving parts are adequately lubricated to reduce friction and wear, thereby extending the lifespan of the equipment.

4. Temperature Monitoring

Regularly monitor the temperature settings to maintain optimal processing conditions. Variations can lead to product inconsistencies.

5. Professional Servicing

Engage professional services for thorough maintenance checks and to address any technical issues that may arise during operation.

FAQs About PET Single Screw Extruders

1. What is the main advantage of a single screw extruder over a twin screw extruder?

Single screw extruders are generally simpler in design, making them easier to maintain and operate, while still offering high throughput rates for many applications.

2. Can PET be recycled after extrusion?

Yes, PET is highly recyclable, and products made from PET can be reprocessed using single screw extruders to create new items.

3. What is the typical temperature range for PET extrusion?

The typical temperature range for PET extrusion is between 220°C and 260°C, depending on the specific formulation and application requirements.

4. How does screw design affect PET processing?

Screw design affects the material flow, mixing efficiency, and heat transfer, which are critical for producing high-quality PET products.

5. What are some common issues faced when operating PET single screw extruders?

Common issues include material degradation, inconsistent melting, and die blockages, often stemming from improper temperature settings or material feed rates.

Conclusion

Understanding the mechanics of PET single screw extruders is crucial for manufacturers aiming to optimize their production processes. By grasping the intricate components and operation of these machines, professionals can enhance product quality, boost efficiency, and reduce operational costs. As the demand for PET products continues to grow, mastering the nuances of single screw extruders will undoubtedly position companies for success in the competitive manufacturing landscape.

RELATED INFORMATION

Why Choose Conical Twin Screw for Your Next Extrusion Project?

Why Choose Conical Twin Screw for Your Next Extrusion Project? Understanding Extrusion Technology In the realm of **plastic processing**, extrusion is an essential manufacturing technique that transforms raw plastic materials into usable products. The **extrusion process** involves forcing molten plastic through a die to create continuous shapes like sheets, films, and profiles. With advancements

Understanding the Advantages of Counter Rotating Twin Screw Extruders for Plastic Processing

Counter rotating twin screw extruders are pivotal in the plastic processing industry, recognized for their versatility and efficiency. Unlike single screw extruders, twin screw extruders feature two intermeshing screws that rotate in opposite directions. This design allows for enhanced material handling and processing capabilities, making them suitable for a wide array of applications. One of the