Understanding the Benefits and Applications of PET Single Screw Extruders

2025-12

One of the primary advantages of PET single screw extruders is their ability to achieve high throughputs while maintaining consistent melt quality. The single screw design allows for efficient material transport and mixing, which is essential for processing PET, a material that can be challenging due to its high viscosity. The design optimizes the melting and homogenization processes, ensuring a uniform output that meets stringent quality standards.

Another benefit of using PET single screw extruders is their adaptability to various formulations. Whether working with recycled PET or adding additives to enhance performance, these extruders can be easily adjusted to accommodate different material properties. This flexibility helps manufacturers respond quickly to market demands and innovate new product offerings without significant downtime or investment in new machinery.

Additionally, PET single screw extruders are often equipped with advanced control systems that facilitate precise monitoring of temperature and pressure during the extrusion process. Such features are critical for processing PET, as they help prevent thermal degradation, which can compromise the material's properties. By maintaining optimal processing conditions, manufacturers can ensure high-quality end products that meet customer expectations.

Furthermore, energy efficiency is an important aspect of PET single screw extruders. Many modern machines are designed with energy-saving technologies that reduce power consumption without sacrificing performance. This not only lowers operational costs but also aligns with the growing demand for sustainable manufacturing practices in the plastic industry.

In conclusion, PET single screw extruders offer a range of advantages that can significantly enhance production efficiency and product quality in plastic processing. Their ability to handle various formulations, maintain consistent output, and operate with energy efficiency makes them an invaluable asset for manufacturers looking to innovate and remain competitive in the market. Understanding these machines' functionalities and benefits can empower businesses to make informed decisions regarding their plastic manufacturing processes.

Previous Page:

RELATED INFORMATION

Understanding the Benefits and Applications of PET Single Screw Extruders

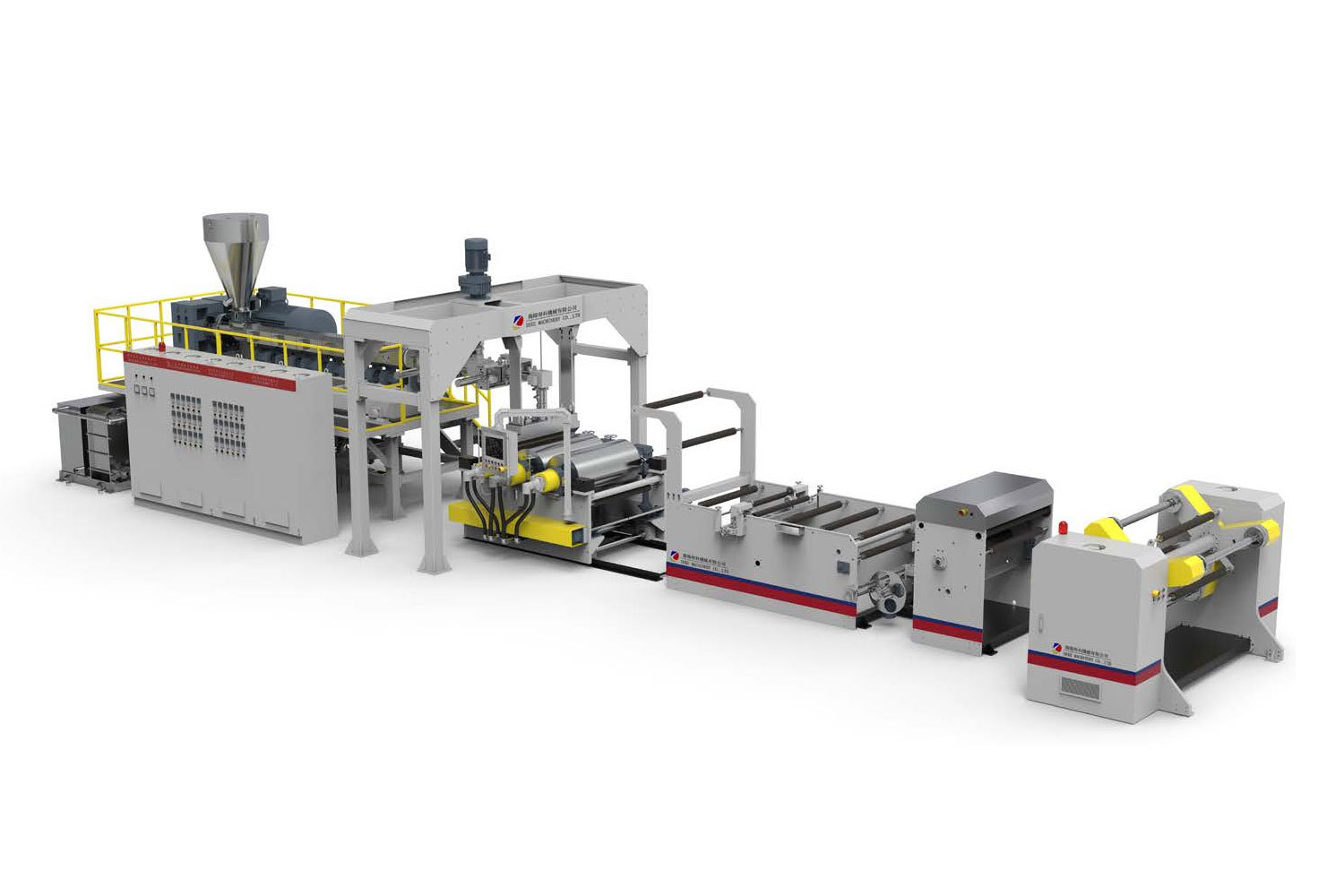

In the realm of plastic processing machinery, PET single screw extruders have gained significant traction due to their efficiency and versatility. These machines are specifically designed to process Polyethylene Terephthalate (PET), a widely used thermoplastic polymer known for its excellent mechanical properties and recyclability. Understanding the key features and benefits of PET single screw ex

Top Trends in Plastic Extrusion: The Rise of PET Sheet Technology

Top Trends in Plastic Extrusion: The Rise of PET Sheet Technology Introduction to Plastic Extrusion and PET Sheets Plastic extrusion has become a cornerstone of modern manufacturing, enabling the production of diverse plastic products with high efficiency. Among the various materials processed, **Polyethylene Terephthalate** (PET) has gained significant traction, especially in the form of sheets.