Exploring the Versatility of PET Extrusion Sheet Lines Across Industries

2025-12

Exploring the Versatility of PET Extrusion Sheet Lines Across Industries

Introduction to PET Extrusion Technology

In the rapidly evolving landscape of manufacturing, the focus has shifted towards materials that provide durability, flexibility, and sustainability. **Polyethylene Terephthalate (PET)** has emerged as a frontrunner in this regard, particularly through its application in **extrusion sheet lines**. These lines not only streamline production processes but also cater to a diverse range of industries. In this article, we will delve into the various applications and advantages of PET extrusion sheets, providing a comprehensive understanding of their transformative impact.

The Production Process of PET Extrusion Sheets

Understanding the Extrusion Process

The extrusion of PET sheets involves a meticulous process where **plastic pellets** are heated and melted to create a continuous sheet. The process starts with the **feeding system**, where raw PET pellets are introduced into the extruder. This is followed by several key stages:

- Melting: The pellets are heated to a specific temperature, causing them to melt and become a homogeneous material.

- Extrusion: The melted PET is forced through a die to shape it into a sheet. The die can be customized to produce various thicknesses and widths.

- Cooling and Calibration: The newly formed sheet is cooled using air or water, ensuring it retains its shape. It's then calibrated to meet specific industry standards.

- Cutting and Finishing: After cooling, the sheets are cut to the required dimensions and undergo additional finishing processes, such as surface treatment or coating.

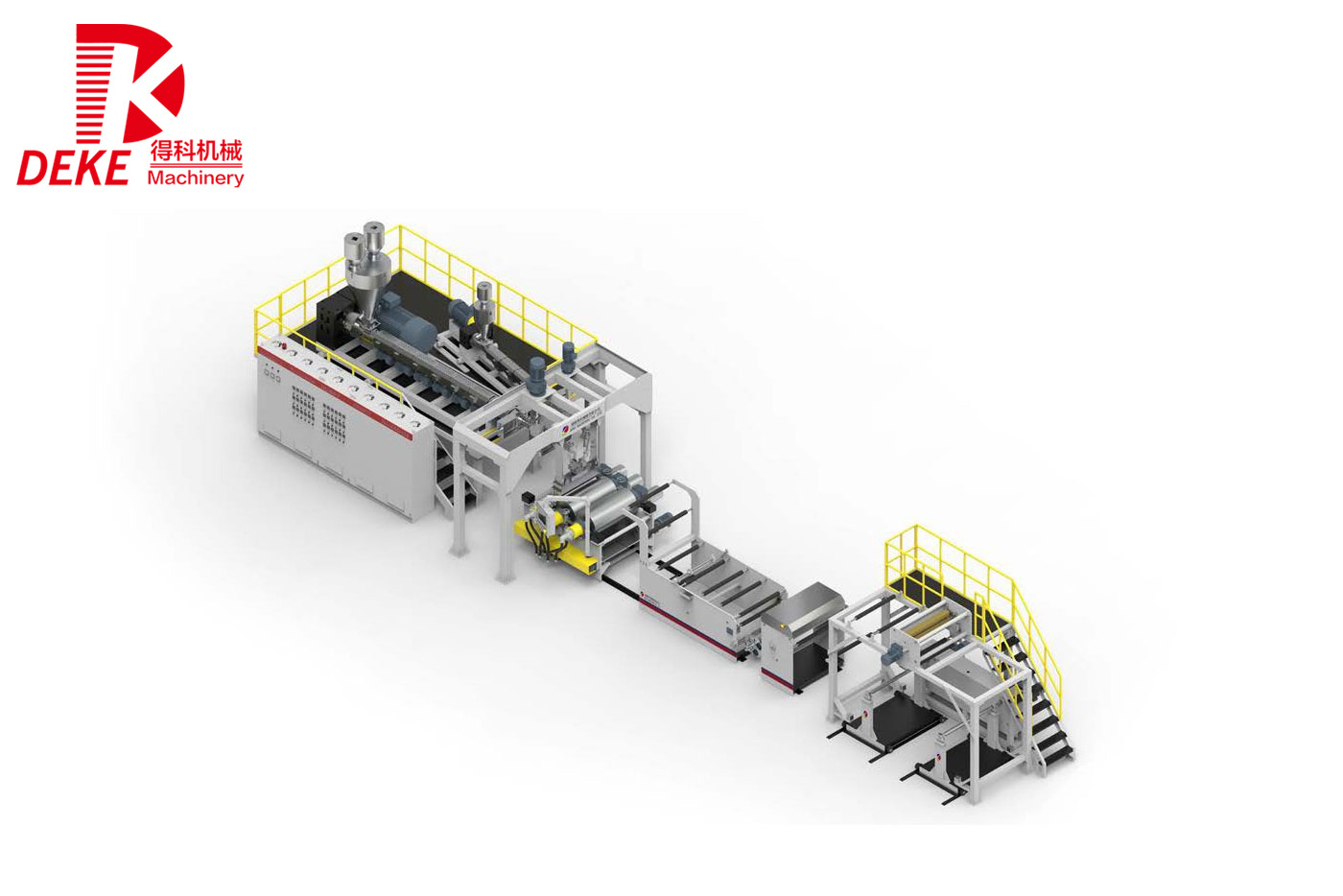

Key Equipment Used in PET Extrusion

The efficiency of PET extrusion relies heavily on the machinery involved. Key equipment includes:

- Single and Twin-Screw Extruders: These are crucial for melting and mixing the PET pellets.

- Cooling Units: Essential for maintaining the integrity of the sheets post-extrusion.

- Die Heads: Customized die heads enable the production of sheets in various shapes and sizes.

Applications of PET Extrusion Sheets Across Industries

1. Packaging Industry

The packaging industry is one of the most significant beneficiaries of PET extrusion technology. **PET sheets** are extensively used in the production of containers, trays, and blister packs. Their lightweight nature, coupled with excellent barrier properties against moisture and gases, makes them ideal for food packaging.

Advantages in Packaging

- Recyclability: PET sheets are 100% recyclable, aligning with global sustainability goals.

- Cost-Effectiveness: Their lightweight properties contribute to lower shipping costs.

- Printability: The surface of PET sheets allows for high-quality printing, enhancing branding opportunities.

2. Construction Industry

In construction, PET extrusion sheets serve as reliable alternatives to traditional materials. They are used in applications such as **roofing, wall cladding, and glazing**. The durability and weather resistance of PET sheets ensure longevity and reduce maintenance costs.

Benefits in Construction

- Energy Efficiency: Reflective PET sheets can help in reducing energy consumption for temperature regulation.

- Lightweight Design: Their reduced weight simplifies handling and installation.

- Design Flexibility: PET sheets can be customized to achieve various aesthetic outcomes.

3. Automotive Industry

In the automotive sector, PET extrusion sheets are increasingly utilized for **interior and exterior components**. From dashboard panels to light lenses, the versatility of PET allows for innovative design solutions that enhance vehicle aesthetics and functionality.

Prospects in Automotive Applications

- Impact Resistance: PET sheets provide enhanced durability against impacts and scratches.

- Weight Reduction: Using PET helps in reducing the overall weight of vehicles, improving fuel efficiency.

- Safety Features: PET’s ability to withstand high temperatures makes it suitable for various automotive applications.

4. Electronics Industry

The electronics industry benefits from PET extrusion sheets for insulation and protective coverings. Their electrical insulation properties make them essential for **circuit boards** and other electronic components.

Key Advantages in Electronics

- Thermal Stability: PET sheets maintain performance under varying temperature conditions.

- Moisture Resistance: They protect sensitive electronic components from moisture damage.

- Customization: PET sheets can be tailored to specific electronic needs, such as thickness and surface finish.

The Environmental Impact of PET Sheets

Recycling and Sustainability

One of the most compelling advantages of PET extrusion sheets is their **environmental friendliness**. The recycling process for PET is well-established; recycled PET (rPET) can be transformed back into pellets for manufacturing new sheets, significantly reducing carbon footprints.

Innovative Recycling Techniques

The recycling of PET involves several innovative techniques, including **mechanical recycling, chemical recycling**, and **upcycling**. These methods not only preserve the quality of the material but also contribute to a closed-loop system that minimizes waste.

Future Trends in PET Extrusion Technology

As industries continue to pivot towards sustainability, the future of PET extrusion technology looks promising. Innovations such as **bio-based PET**, which uses renewable resources, and advancements in **additive manufacturing** will likely play significant roles in the evolution of PET applications.

Emerging Technologies

Future trends suggest a growing emphasis on **smart PET sheets** equipped with sensors and IoT capabilities to monitor conditions in real-time. These advancements could revolutionize industries by providing data-driven insights for performance optimization.

Challenges and Considerations

Market Competition and Cost Factors

Despite the numerous advantages of PET extrusion sheets, challenges such as **market competition** and **raw material costs** persist. Manufacturers must navigate fluctuating prices and a competitive landscape to maintain profitability.

Quality Control and Standards

Ensuring consistent quality and adhering to industry standards is crucial for manufacturers. Implementing rigorous quality control measures throughout the production process can help mitigate defects and enhance product reliability.

FAQs about PET Extrusion Sheet Lines

1. What are the primary benefits of using PET extrusion sheets in packaging?

PET extrusion sheets offer excellent barrier properties, are lightweight, and are 100% recyclable, making them an ideal choice for sustainable packaging solutions.

2. How does the PET extrusion process differ from other plastic extrusion processes?

The PET extrusion process involves specific temperatures and equipment tailored for melting and shaping PET pellets, distinguishing it from other plastics that may require different temperatures or additives.

3. Are PET sheets suitable for food contact applications?

Yes, PET sheets are FDA-approved for food contact applications, making them safe for food packaging and storage.

4. How can PET sheets contribute to sustainability in construction?

PET sheets are recyclable and can reduce the need for traditional materials, thereby lowering the overall environmental impact of construction projects.

5. What innovations are driving the future of PET extrusion technology?

Innovations such as bio-based PET and smart PET sheets with integrated sensors are set to enhance the functionality and sustainability of PET products in various industries.

Conclusion

**PET extrusion sheets** stand at the forefront of modern manufacturing, demonstrating versatility across industries such as packaging, construction, automotive, and electronics. Their unique properties, coupled with ongoing innovations, position them as a sustainable alternative to traditional materials. As we continue to explore and harness the capabilities of PET technology, the future holds immense potential for further advancements and applications, paving the way for a more sustainable and efficient manufacturing landscape.

Previous Page:

RELATED INFORMATION

Exploring the Versatility of PET Extrusion Sheet Lines Across Industries

Exploring the Versatility of PET Extrusion Sheet Lines Across Industries Introduction to PET Extrusion Technology In the rapidly evolving landscape of manufacturing, the focus has shifted towards materials that provide durability, flexibility, and sustainability. **Polyethylene Terephthalate (PET)** has emerged as a frontrunner in this regard, particularly through its application in **extrusion sh

Understanding the Benefits and Applications of PET Single Screw Extruders

In the realm of plastic processing machinery, PET single screw extruders have gained significant traction due to their efficiency and versatility. These machines are specifically designed to process Polyethylene Terephthalate (PET), a widely used thermoplastic polymer known for its excellent mechanical properties and recyclability. Understanding the key features and benefits of PET single screw ex