2025/02

How a Conical Screw Extruder Can Enhance Your Manufacturing Efficiency

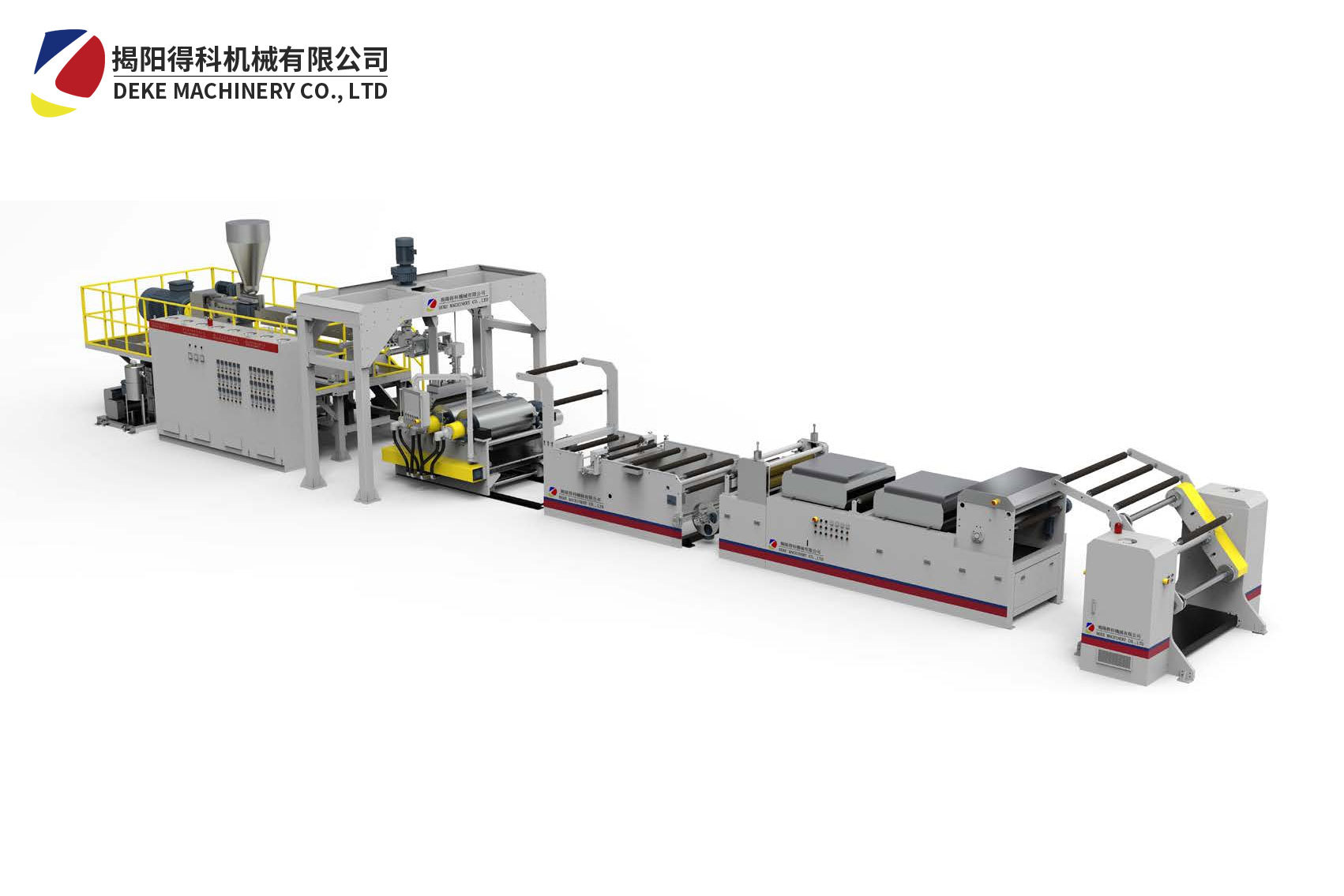

How a Conical Screw Extruder Can Enhance Your Manufacturing Efficiency Manufacturing efficiency is a crucial aspect of any production process, especially in the plastic processing industry. One of the most significant advancements in this field is the **conical screw extruder**. This sophisticated machine can transform the way manufacturers operate, boosting productivity and product quality while

2025/02

Understanding the Functionality and Benefits of Conical Screw Extruders in Plastic Processing

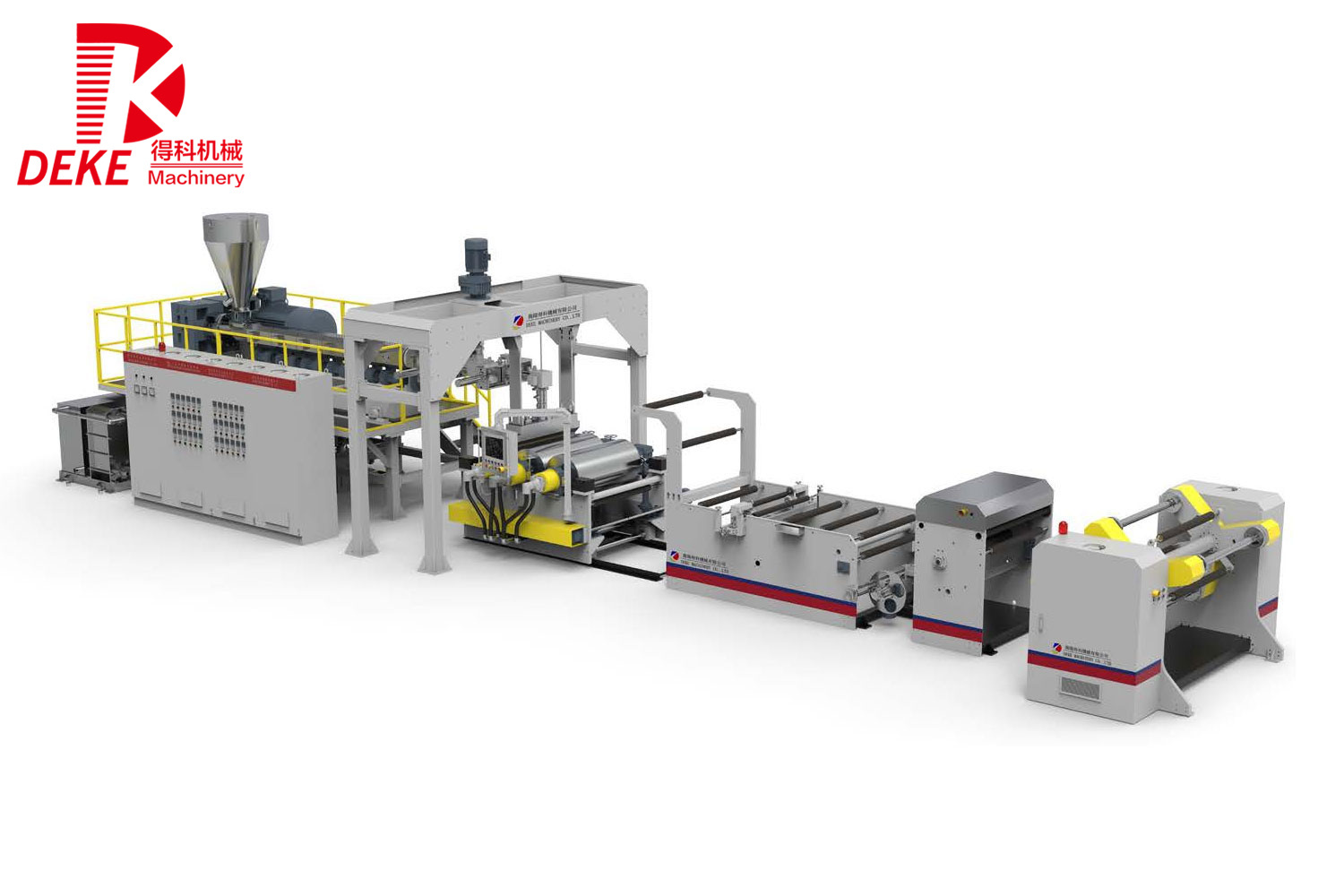

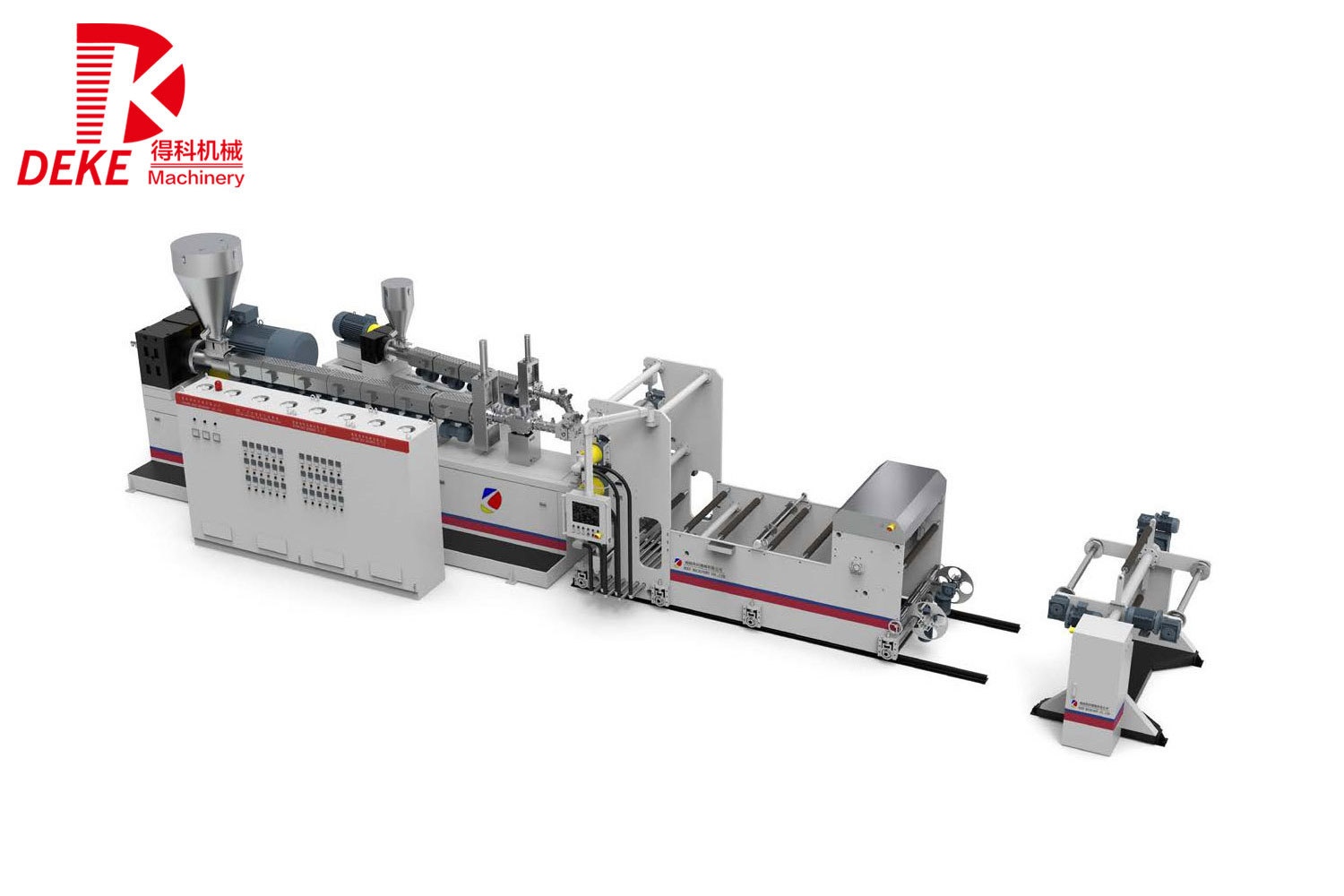

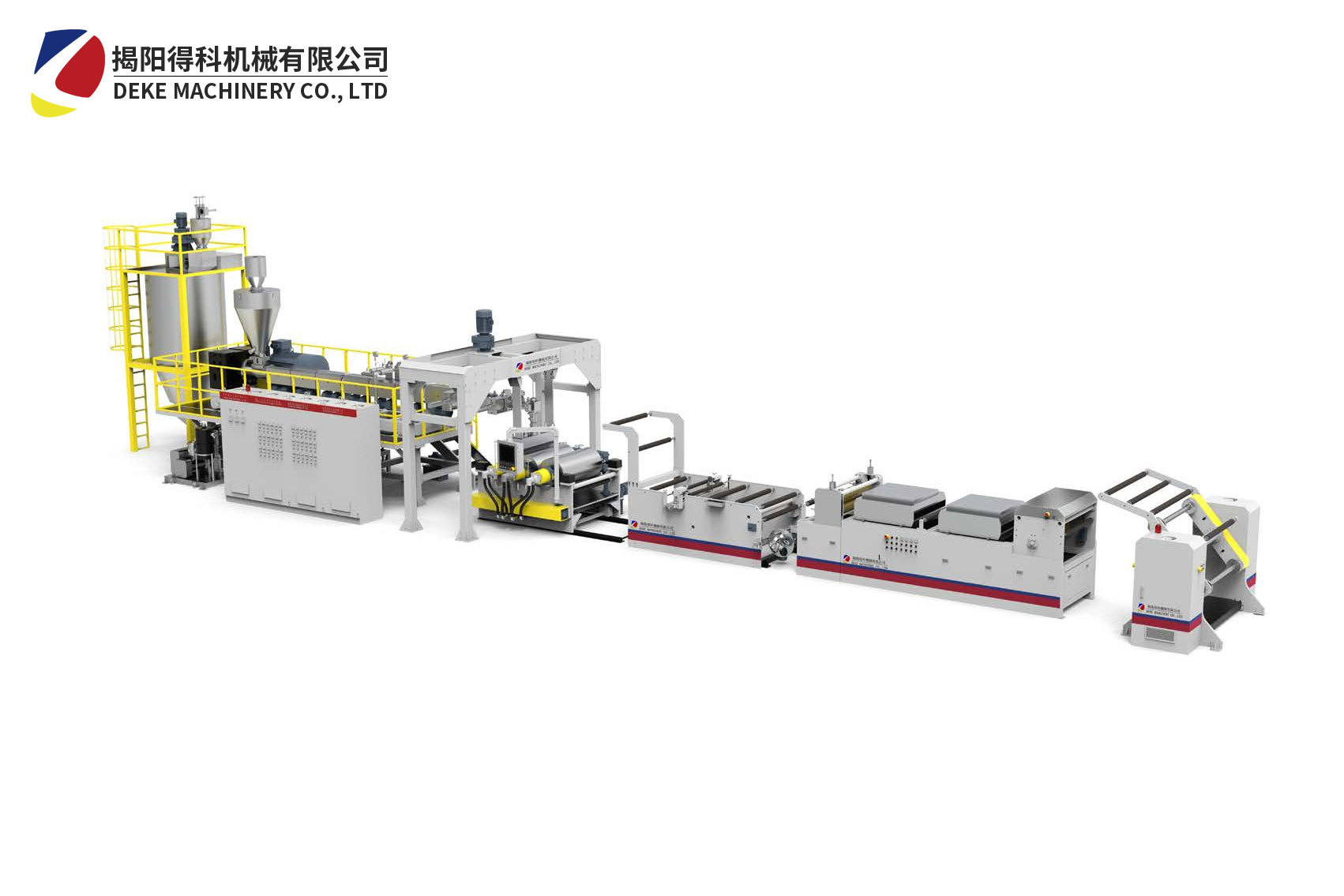

Conical screw extruders are specialized machines used in the plastic processing industry, particularly for the extrusion of various plastic materials. They consist of a conical screw, which is designed to convey, melt, and shape plastic resins into a continuous profile or sheet. Unlike traditional cylindrical screw extruders, the conical design allows for a more efficient melting and mixing proces

2025/02

Unlocking the Benefits of Using a Conical Screw Extruder in Plastic Processing

Unlocking the Benefits of Using a Conical Screw Extruder in Plastic Processing Table of Contents 1. Introduction to Conical Screw Extruders 2. Understanding the Design and Functionality 3. Key Benefits of Conical Screw Extruders 3.1 Enhanced Material Mixing and Homogenization 3.2 Improved Processing Efficiency 3.3 Increased Output Quality and Consistency 3.4 Flexibility in Material Processing 3.5

2025/02

Understanding Twin Screw Compounding Machines: A Key Component in Plastic Processing

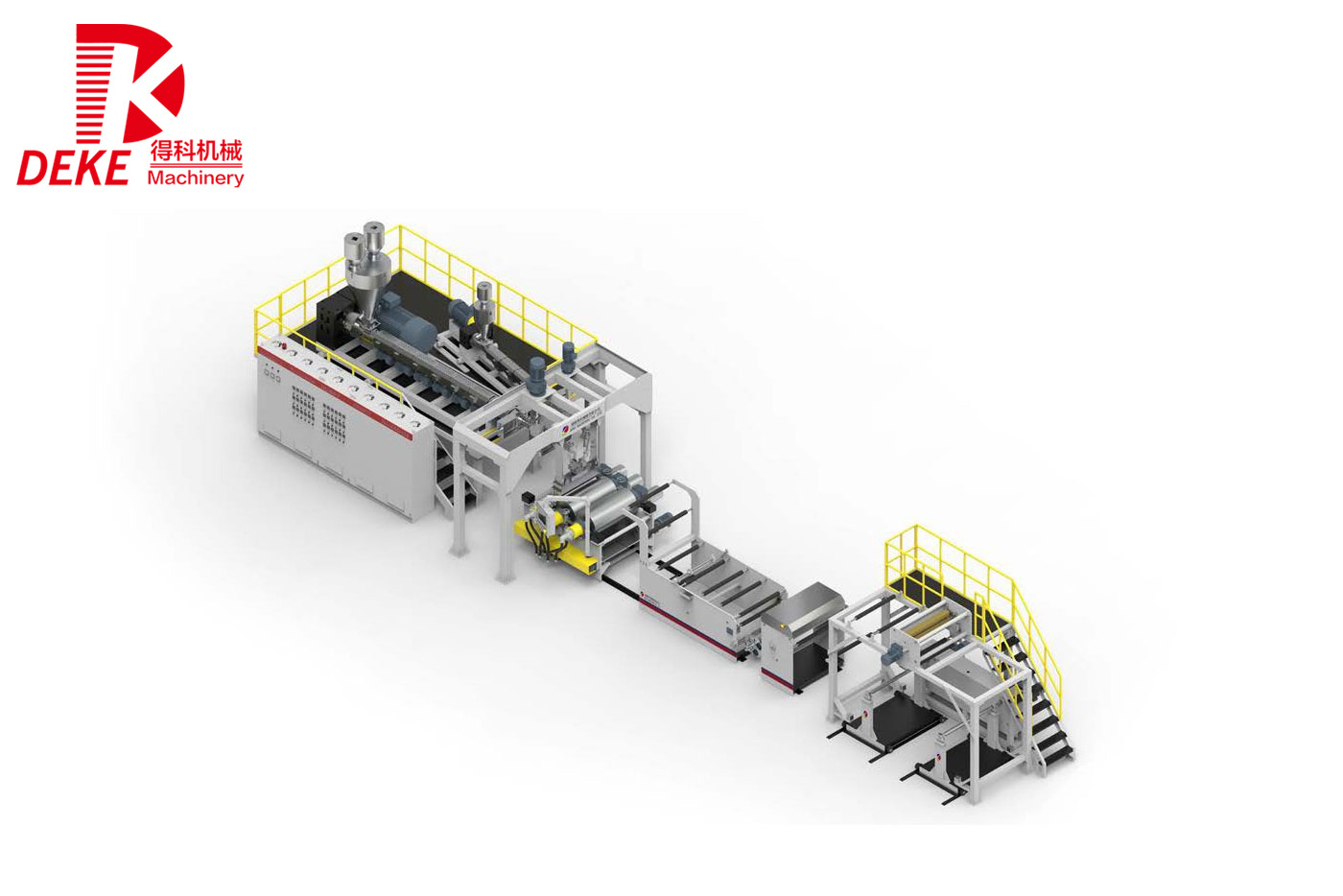

Twin screw compounding machines are critical equipment used in the plastic processing industry, particularly for the compounding and mixing of polymers. These machines utilize two intermeshing screws that rotate in a synchronized manner to effectively blend materials such as polymers, additives, and fillers. The design enhances the mixing process, resulting in a homogeneous product that meets spec

2025/02

Why Choose a Twin Screw Compounding Machine for Your Manufacturing Needs?

Why Choose a Twin Screw Compounding Machine for Your Manufacturing Needs? Understanding Twin Screw Compounding Machines Twin screw compounding machines play a pivotal role in the manufacturing of plastic products. These advanced machines are designed to mix, melt, and compound different materials effectively. They consist of two intermeshing screws that rotate simultaneously, ensuring a thorough b

2025/02

Understanding Twin Screw Compounding Machines: A Key Component in Plastic Processing

Twin screw compounding machines are essential tools within the plastic processing sector, particularly in the manufacturing of various plastic products. These machines operate using two intermeshing screws that rotate simultaneously, allowing for efficient mixing, compounding, and extrusion of plastic materials. The design and functionality of twin screw compounding machines provide a range of adv

2025/02

Unlocking the Potential of Twin Screw Compounding Machines in Plastic Processing

Unlocking the Potential of Twin Screw Compounding Machines in Plastic Processing Table of Contents 1. Introduction to Twin Screw Compounding Machines 2. What is a Twin Screw Compounding Machine? 3. Advantages of Twin Screw Compounding in Plastic Processing 4. Applications of Twin Screw Compounding Machines in the Industry 5. Working Principle of Twin Screw Compou

2025/02

Understanding Conical Twin Screw Extruders: A Key Component in Plastic Processing Machinery

Conical twin screw extruders are specialized machinery widely used in the plastic processing industry to transform raw plastic materials into extruded products. These machines are characterized by their unique conical screw design, which differentiates them from other types of extruders. The conical shape allows for better material mixing, melting, and shaping, making them ideal for various applic

2025/02

The Comprehensive Advantages of Automation in Conical Twin Screw Extruder Operations

The Comprehensive Advantages of Automation in Conical Twin Screw Extruder Operations Table of Contents 1. Introduction to Conical Twin Screw Extruders 2. The Transformative Benefits of Automation 3. Increased Efficiency and Throughput 4. Enhanced Quality Control 5. Reduction in Operating Costs 6. Decreased Labor Dependence 7. Flexibility and Adaptability in Production

2025/02

Understanding the Functionality and Benefits of Conical Twin Screw Extruders in Plastic Processing

Conical twin screw extruders are specialized machines widely used in the plastic processing industry. Their unique design features two intermeshing screws that are arranged in a conical shape. This configuration provides several advantages over traditional single screw extruders, making them particularly well-suited for processing a variety of thermoplastics. One of the primary benefits of conical

RELATED INFORMATION

Understanding the Advantages of PET Twin Screw Extruders in Plastic Manufacturing

The PET twin screw extruder is a vital piece of equipment in the plastic processing industry, particularly for those working with polyethylene terephthalate (PET). This type of extruder offers several advantages that can significantly improve manufacturing efficiency and product quality. One of the primary benefits of PET twin screw extruders is their high mixing capability. The design of twin scr

Understanding the Mechanics of PET Single Screw Extruders: A Comprehensive Guide

Understanding the Mechanics of PET Single Screw Extruders Introduction to PET Single Screw Extruders PET single screw extruders are pivotal in the plastic manufacturing industry. These machines play a crucial role in converting raw PET pellets into a variety of products, ranging from bottles to fibers. Understanding their mechanics is essential for maximizing efficiency and output quality in man