2025/02

How Advanced Control Systems Enhance the Performance of Conical Twin Screw Extruders

How Advanced Control Systems Enhance the Performance of Conical Twin Screw Extruders Introduction In the continuously evolving world of plastic manufacturing, optimizing machinery performance is crucial for achieving high efficiency and quality outputs. One of the pivotal machines in this domain is the conical twin screw extruder. This article delves into how **advanced control systems** play a si

2025/02

Understanding Twin Screw Extruders for Compounding: Key Insights for Manufacturing Professionals

Twin screw extruders are pivotal in the compounding process, particularly within the plastics industry. These machines are designed to mix, melt, and process various materials, ensuring a homogeneous blend that is vital for producing high-quality plastic products. The unique design of twin screw extruders allows for improved material handling and processing capabilities compared to single screw ex

2025/02

Why Choose a Twin Screw Extruder for Your Plastic Compounding Needs?

Why Choose a Twin Screw Extruder for Your Plastic Compounding Needs? Introduction to Twin Screw Extruders in Plastic Compounding The realm of **plastic processing** continues to evolve, leading to increased demand for methods that ensure quality, efficiency, and versatility in manufacturing. At the forefront of these advancements is the **twin screw extruder**, a machine celebrated for its unique

2025/02

Understanding Twin Screw Extruders for Compounding: An Essential Guide

Twin screw extruders are integral machines in the realm of plastic processing, especially when it comes to compounding. Unlike single screw extruders, twin screw extruders utilize two parallel screws that rotate in the same or opposite directions. This design allows for superior mixing, kneading, and shearing of materials, which is essential in producing high-quality compounded products. One of th

2025/02

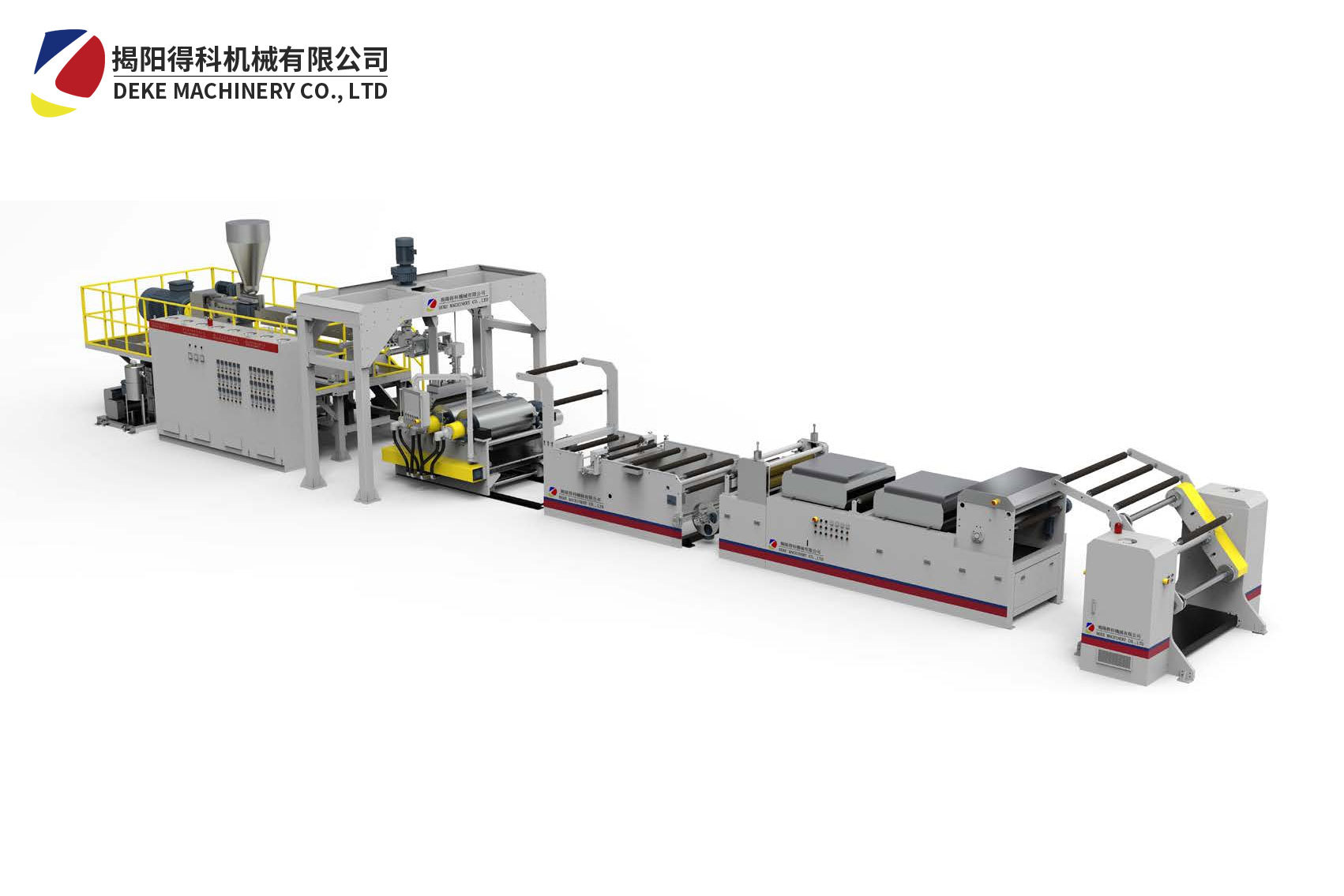

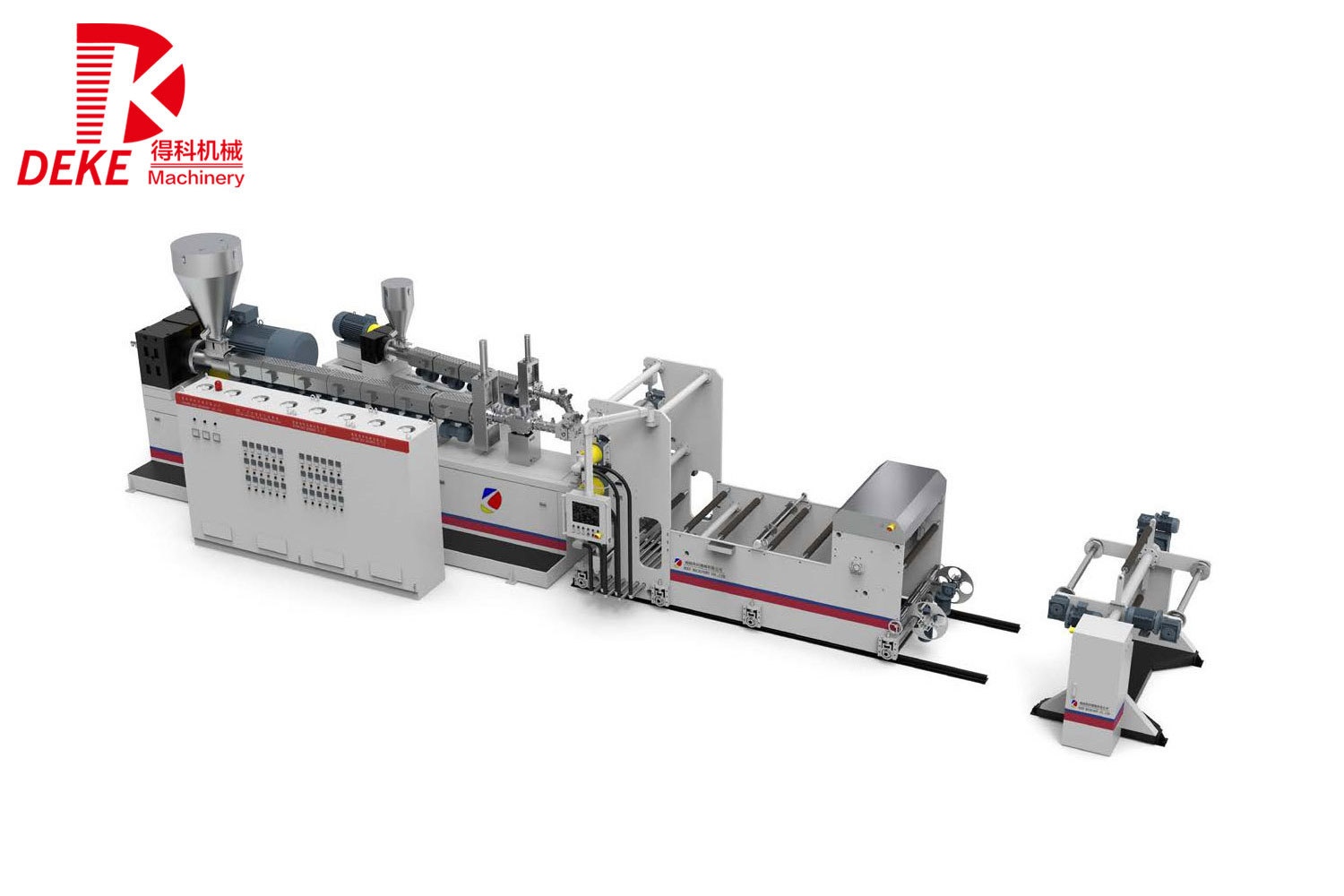

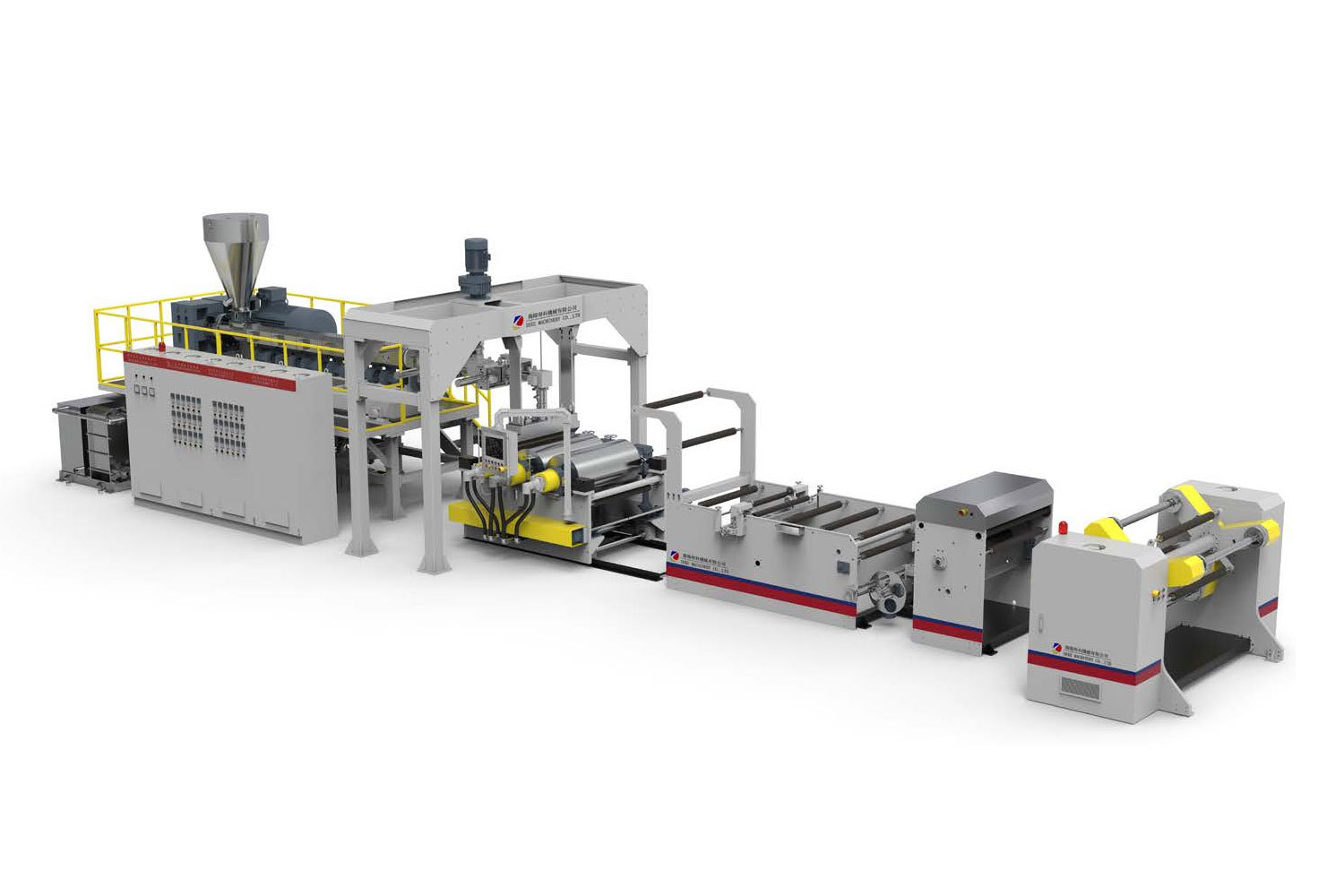

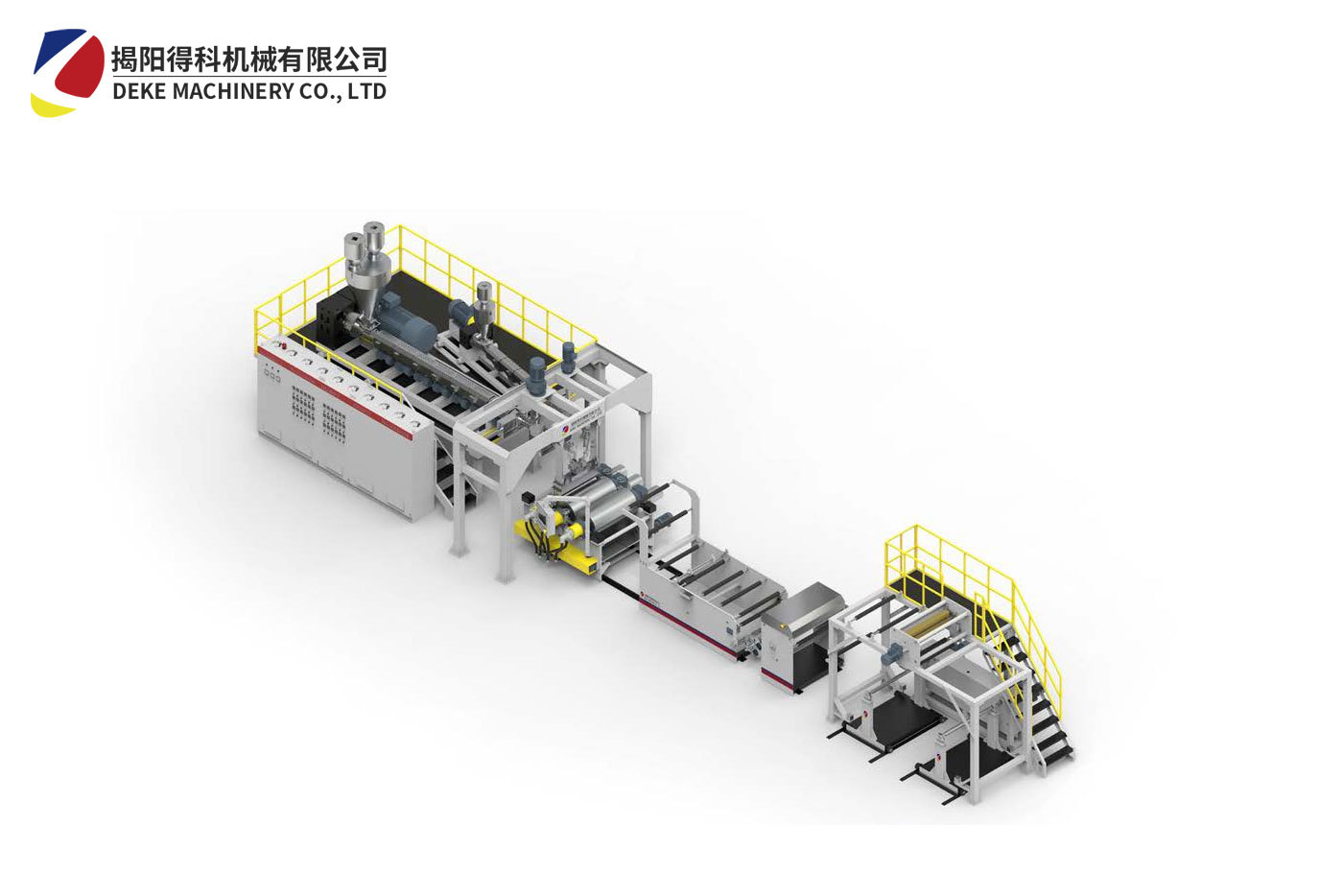

EVOH High Barrier Sheet Extruder

EVOH High Barrier Sheet Extruder is an advanced equipment specially used for producing EVOH high barrier sheet. In many fields such as modern packaging, food preservation, and medicine, the barrier properties of materials are extremely high, and the EVOH sheets produced by this extruder can effectively meet these requirements.

2025/02

Understanding the Role of Twin Screw Extruders in Modern Compounding: A Comprehensive Insight

Understanding the Role of Twin Screw Extruders in Modern Compounding In the manufacturing and processing of plastics, the importance of high-quality machinery cannot be overstated. Among these machines, **twin screw extruders** have emerged as a pivotal technology, particularly in modern compounding processes. This article delves into their functionality, advantages, and the various applications t

2025/02

Understanding the Role of Compounding Twin Screw Extruders in Plastic Processing

Compounding twin screw extruders play a pivotal role in the plastic processing industry, particularly in the manufacturing of high-quality plastic materials. These machines are designed for the compounding of various materials, which involves mixing, melting, and homogenizing polymers with additives. The twin screw design provides several advantages over single screw extruders, making it a preferr

2025/02

How a Compounding Twin Screw Extruder Revolutionizes Plastic Manufacturing

How a Compounding Twin Screw Extruder Revolutionizes Plastic Manufacturing Table of Contents 1. Introduction to Compounding Twin Screw Extruders 2. What is a Twin Screw Extruder? 3. Benefits of Compounding Twin Screw Extruders 4. Applications in Plastic Manufacturing 5. How Compounding Twin Screw Extruders Work 6. Innovations and Technologies in Twin Screw Extrusion 7. Maintenance a

2025/02

Unlocking the Potential of Compounding Twin Screw Extruders in Plastic Processing

In the realm of plastic processing machinery, the compounding twin screw extruder stands out as a versatile and efficient tool. Designed for the compounding of polymers, these extruders utilize two intermeshing screws that rotate in the same direction. This unique configuration allows for exceptional mixing and melting capabilities, making them ideal for producing high-performance materials. One o

2025/02

Understanding the Benefits of a Compounding Twin Screw Extruder in Plastic Processing

Understanding the Benefits of a Compounding Twin Screw Extruder in Plastic Processing Table of Contents 1. Introduction to Compounding Twin Screw Extruders 2. What is a Twin Screw Extruder? 3. Key Components of a Compounding Twin Screw Extruder 4. Benefits of Compounding Twin Screw Extruders 4.1 Enhanced Mixing Capabilities 4.2 Increased Production Efficiency 4.3 Versatility in Material Processing

RELATED INFORMATION

Understanding the Advantages of PET Twin Screw Extruders in Plastic Manufacturing

The PET twin screw extruder is a vital piece of equipment in the plastic processing industry, particularly for those working with polyethylene terephthalate (PET). This type of extruder offers several advantages that can significantly improve manufacturing efficiency and product quality. One of the primary benefits of PET twin screw extruders is their high mixing capability. The design of twin scr

Understanding the Mechanics of PET Single Screw Extruders: A Comprehensive Guide

Understanding the Mechanics of PET Single Screw Extruders Introduction to PET Single Screw Extruders PET single screw extruders are pivotal in the plastic manufacturing industry. These machines play a crucial role in converting raw PET pellets into a variety of products, ranging from bottles to fibers. Understanding their mechanics is essential for maximizing efficiency and output quality in man