2025/01

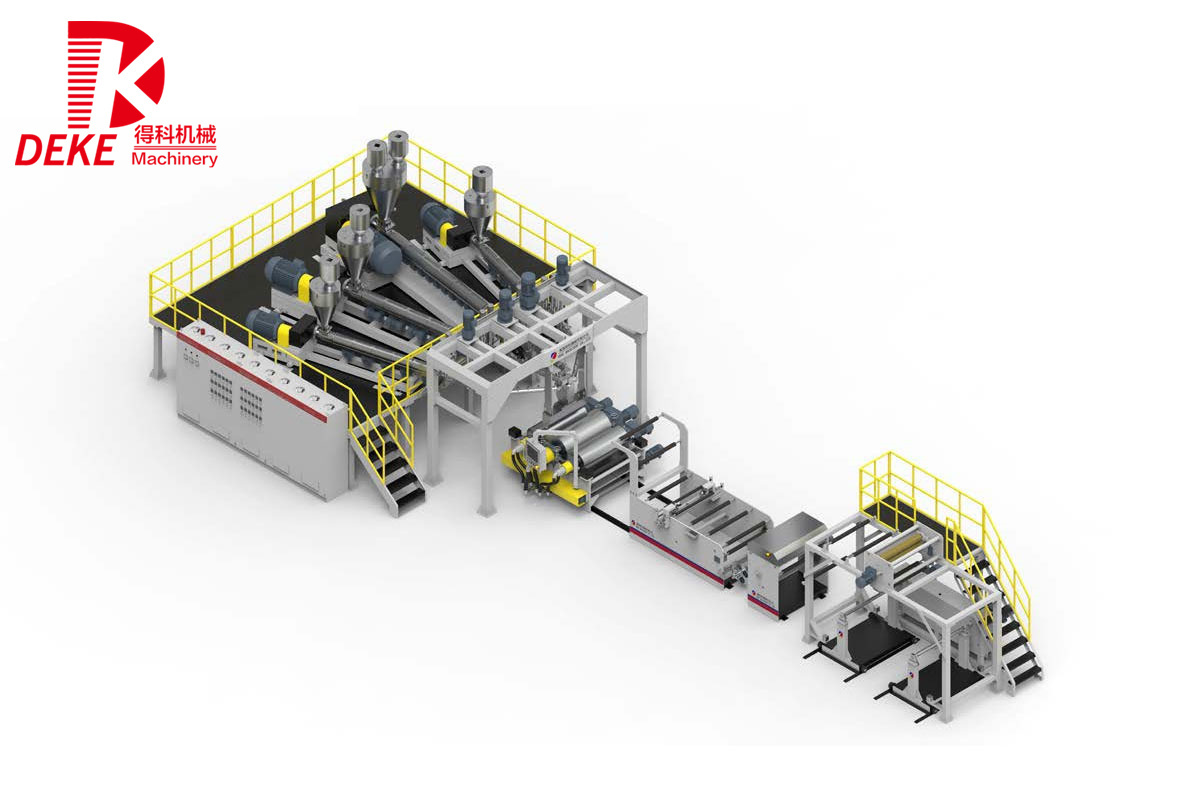

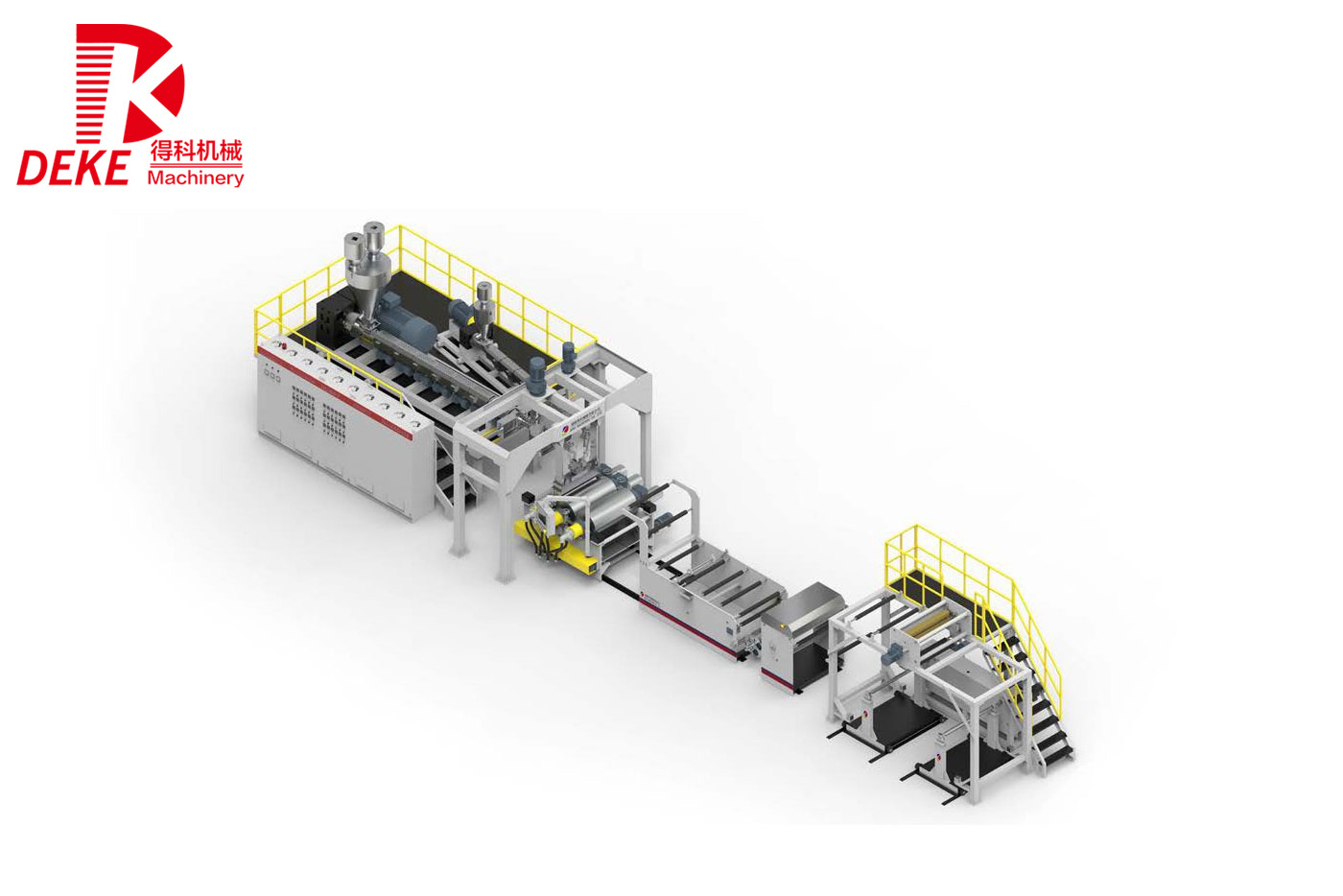

Understanding HIPS Sheet Extruders: A Key Component in Plastic Manufacturing

HIPS, or High Impact Polystyrene, is a versatile thermoplastic widely used in various applications, including packaging, consumer goods, and automotive components. The manufacturing of HIPS sheets involves a critical piece of equipment known as the HIPS sheet extruder. Understanding how these extruders work can provide valuable insights into the plastic processing industry and its implications for

2025/01

Exploring the Benefits of HIPS Sheet Extrusion for Plastic Processing: A Comprehensive Guide

Exploring the Benefits of HIPS Sheet Extrusion for Plastic Processing Table of Contents 1. Introduction to HIPS Sheet Extrusion 2. What is HIPS? 3. Advantages of HIPS Sheet Extrusion 3.1 Strength and Durability 3.2 Versatility in Applications 3.3 Cost-Effectiveness 3.4 Ease of Processing 3.5 Environmental Considerati

2025/01

Understanding HIPS Sheet Extruders: Key Insights for Professionals

High Impact Polystyrene (HIPS) is a widely used thermoplastic material known for its strength, durability, and versatility. HIPS sheet extruders are specialized machines designed to produce sheets of HIPS through a continuous extrusion process. Understanding the operation and benefits of HIPS sheet extruders can greatly enhance the efficiency and quality of your production line. The extrusion proc

2025/01

Maximizing Efficiency: The Crucial Role of HIPS Sheet Extruders in Modern Manufacturing

Maximizing Efficiency: The Crucial Role of HIPS Sheet Extruders in Modern Manufacturing Table of Contents Introduction to HIPS and Its Applications What Are HIPS Sheet Extruders? Benefits of Using HIPS Sheet Extruders How HIPS Sheet Extruders Work Applications of HIPS Sheets in Various Industries Choosing the Right HIPS Sheet Extruder for Your Needs Maintenance and Opt

2025/01

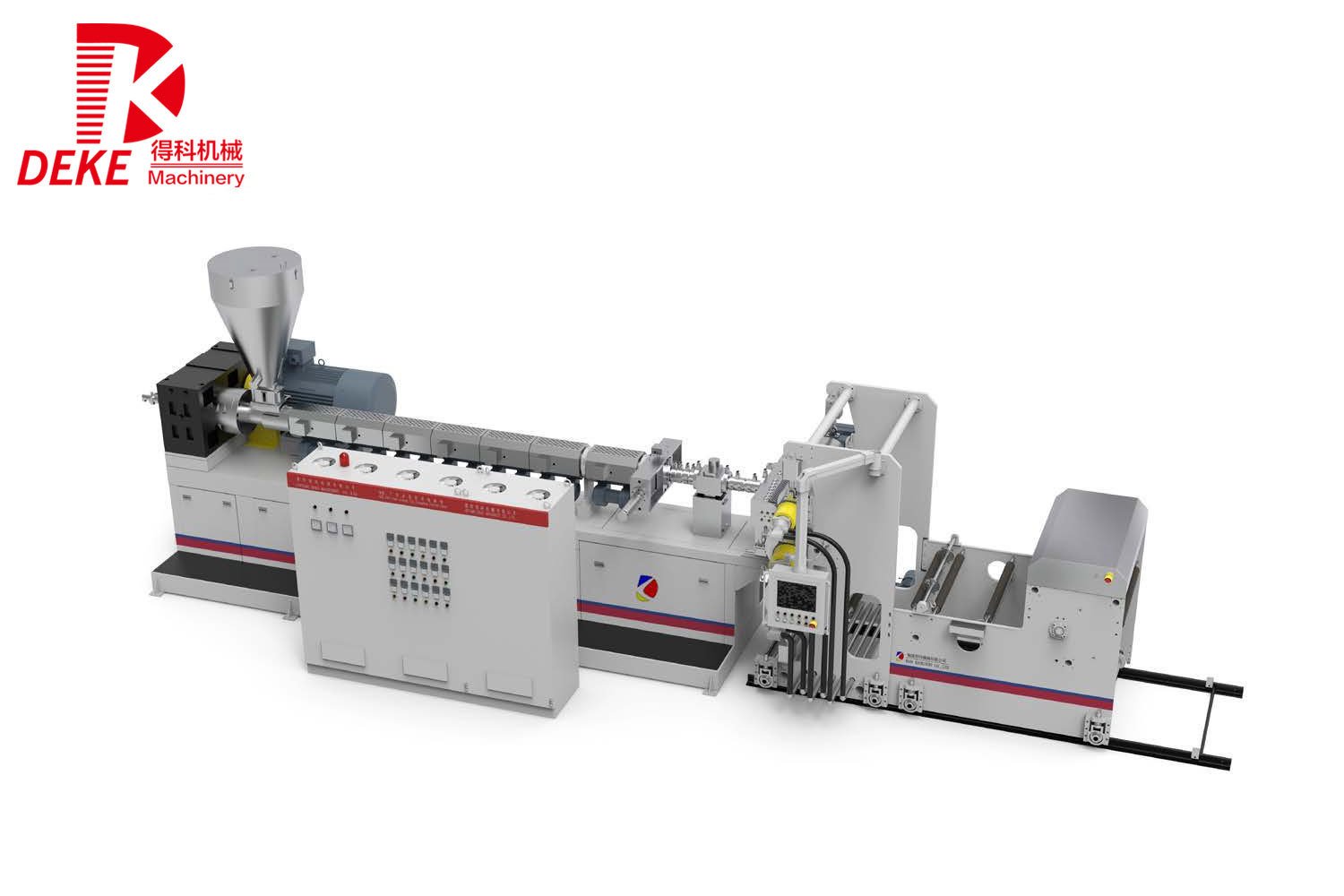

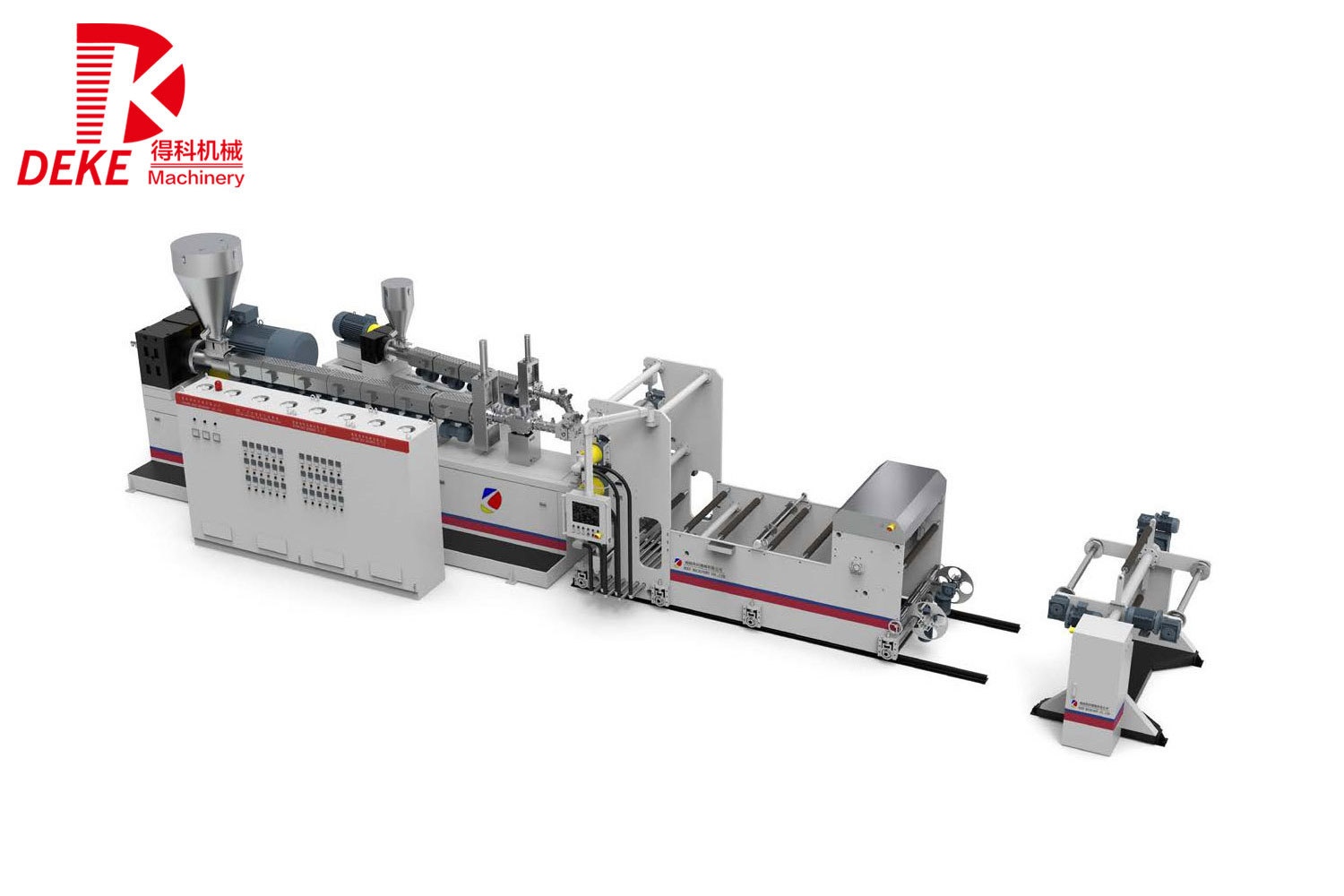

Understanding the Benefits and Applications of Counter Rotating Twin Screw Extruders

Counter rotating twin screw extruders are advanced machines designed to process various thermoplastic materials through a unique configuration of two screws that rotate in opposite directions. This innovative design allows for improved mixing, kneading, and conveying of materials, making these extruders an essential tool in the plastics industry. One of the primary advantages of counter rotating t

2025/01

Why Choose Counter Rotating Twin Screw Extruders for Your Manufacturing Needs?

Why Choose Counter Rotating Twin Screw Extruders for Your Manufacturing Needs? Table of Contents Introduction: The Importance of Extrusion in Manufacturing What Are Counter Rotating Twin Screw Extruders? Benefits of Counter Rotating Twin Screw Extruders Increased Efficiency Better Mixing and Compounding Enhanced Thermal Control

2025/01

Understanding the Mechanics and Advantages of Counter Rotating Twin Screw Extruders

Counter rotating twin screw extruders are sophisticated machines designed for the processing of a wide variety of plastic materials. Their unique configuration, where two screws rotate in opposite directions, allows for enhanced mixing, kneading, and conveying of materials. This design not only improves the efficiency of the extrusion process but also enhances the quality of the end product. One o

2025/01

Unlocking Efficiency: The Comprehensive Advantages of Counter Rotating Twin Screw Extruders

Unlocking Efficiency: The Comprehensive Advantages of Counter Rotating Twin Screw Extruders Table of Contents 1. Introduction to Counter Rotating Twin Screw Extruders 2. How Counter Rotating Twin Screw Extruders Work 3. Key Benefits of Counter Rotating Twin Screw Extruders 3.1 Enhanced Flexibility in Processing 3.2 Increased Processing Efficiency 3.3

2025/01

The Essential Guide to Intermeshing Twin Screw Extruders in Plastic Processing

Intermeshing twin screw extruders are a cornerstone technology in the plastic processing industry, renowned for their efficiency and versatility. Unlike single-screw extruders, which rely on a single screw to convey and process materials, intermeshing twin screw extruders utilize two interlocked screws that rotate in the same direction. This unique design allows for effective melting, mixing, and

2025/01

Why Choose Intermeshing Twin Screw Extruders for Your Manufacturing Needs?

Why Choose Intermeshing Twin Screw Extruders for Your Manufacturing Needs? Manufacturing industries are increasingly turning to modern machinery to enhance efficiency and reduce costs. One such innovative machine is the intermeshing twin screw extruder. This article delves into the numerous benefits of using these extruders, providing an extensive overview that positions them as the preferred choi

RELATED INFORMATION

Understanding the Mechanics of PET Single Screw Extruders: A Comprehensive Guide

Understanding the Mechanics of PET Single Screw Extruders Introduction to PET Single Screw Extruders PET single screw extruders are pivotal in the plastic manufacturing industry. These machines play a crucial role in converting raw PET pellets into a variety of products, ranging from bottles to fibers. Understanding their mechanics is essential for maximizing efficiency and output quality in man

Understanding Twin Screw Compounders: Enhancing Plastic Processing Efficiency

Twin screw compounders are essential machines in the plastic processing industry, particularly in the manufacturing of polymers and composites. These sophisticated devices are designed to melt, mix, and compound plastic materials efficiently. Their unique configuration, featuring two intermeshing screws, allows for improved material handling and processing capabilities compared to single screw ext