2025/10

Innovations in Twin Screw Extruder Technology for Enhanced Compounding

Innovations in Twin Screw Extruder Technology for Enhanced Compounding Table of Contents Introduction to Twin Screw Extruder Technology What is Twin Screw Extrusion? Importance of Compounding in Plastic Manufacturing Recent Innovations in Twin Screw Extruders Advanced Materials in Twin Screw Extruders Smart Technology Integration Energy

2025/10

Exploring the Benefits and Applications of Twin Screw Compounders in Plastics Processing

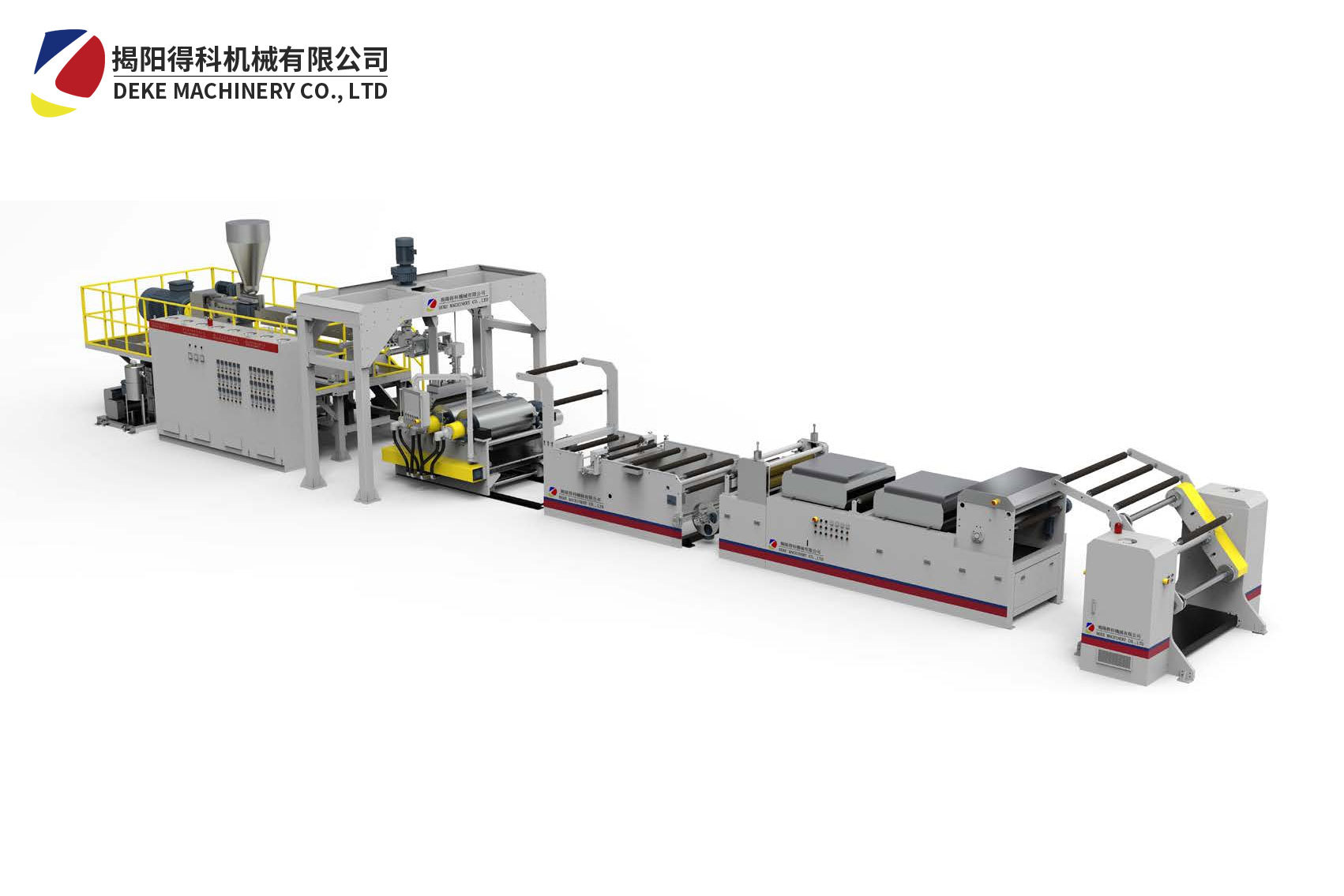

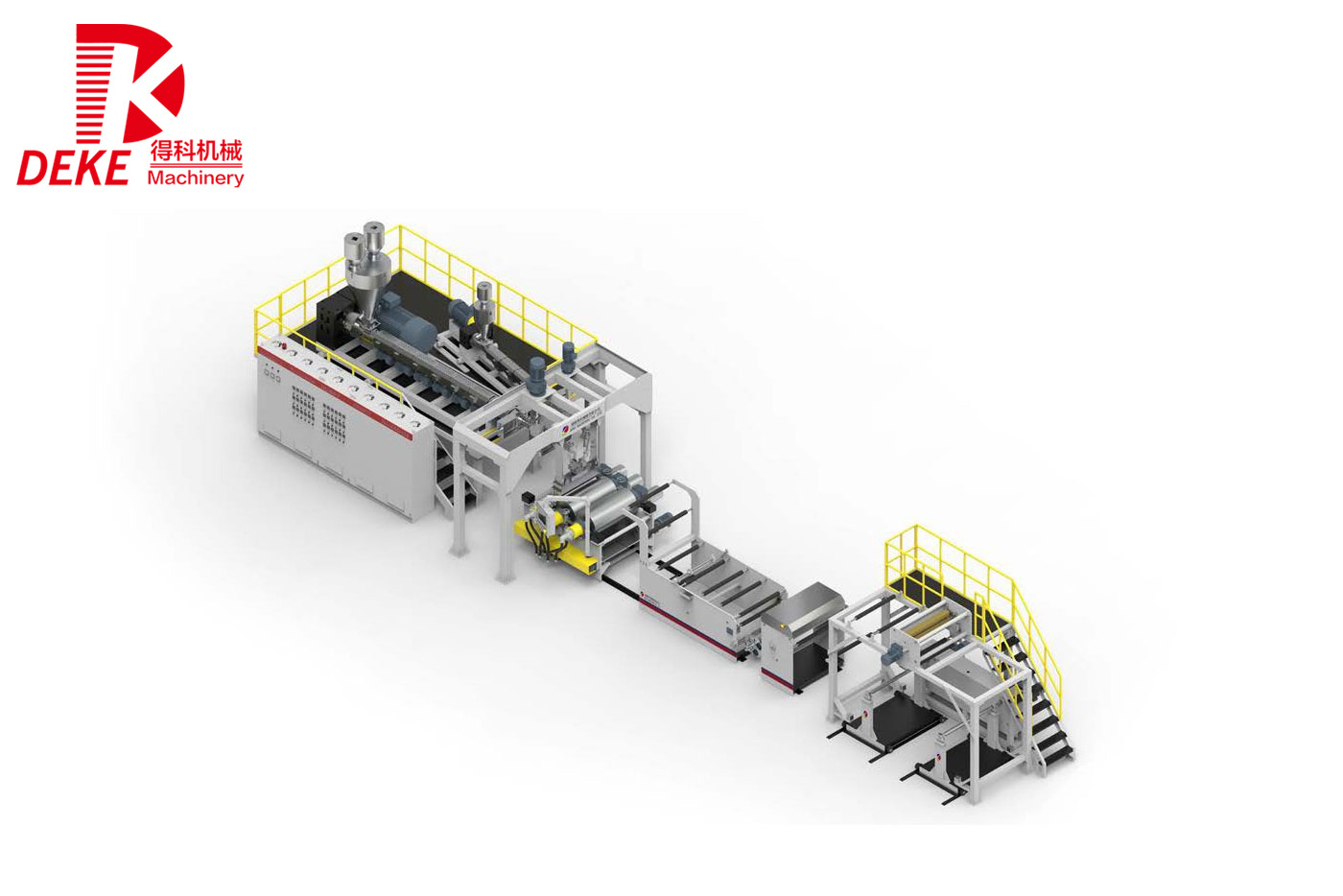

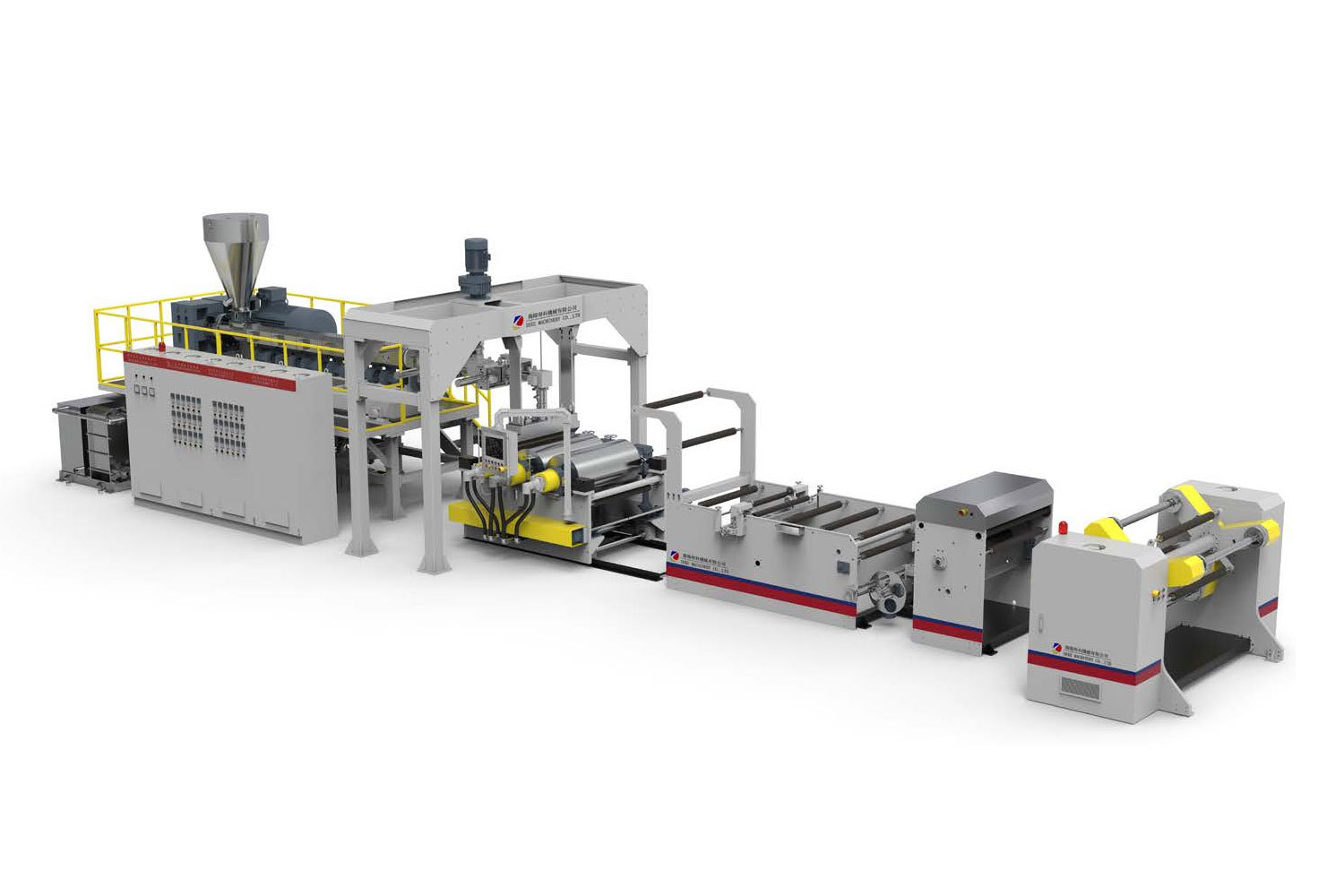

In the realm of manufacturing processing machinery, particularly within the plastics processing sector, twin screw compounders stand out as highly efficient and versatile machines. These systems consist of two intermeshing screws that rotate within a heated barrel, allowing for the precise mixing, compounding, and extrusion of various plastic materials. The unique design of twin screw compounders

2025/10

Understanding the Fundamentals of PET Extrusion Sheet Line Processes

Understanding the Fundamentals of PET Extrusion Sheet Line Processes Table of Contents Introduction to PET Extrusion What is PET Extrusion? The PET Extrusion Process Explained Material Preparation Melting and Extrusion Sheet Cooling Cutting and Finishing Types of PET Extrusion Machines

2025/10

Unlocking the Potential of PLA Sheet Extruder Series for Efficient Plastic Processing

The PLA Sheet Extruder Series represents a significant advancement in the field of plastic processing machinery, particularly for businesses focusing on sustainable materials. Polylactic acid, derived from renewable resources such as corn starch, is an eco-friendly alternative to traditional petroleum-based plastics. The extruder series is designed to efficiently process PLA, allowing manufacturer

2025/10

Exploring the Advantages of Conical Extruders in Plastic Production

Exploring the Advantages of Conical Extruders in Plastic Production Table of Contents Introduction to Conical Extruders What Are Conical Extruders? Operational Efficiency of Conical Extruders Key Advantages of Conical Extruders Superior Temperature Control Enhanced Material Mixing Capabilities Space-Saving Design Cost-Effect

2025/09

Understanding the Advantages of Compounding Twin Screw Extruders in Plastic Processing

Compounding twin screw extruders are advanced machines that play a crucial role in the plastic processing industry. These extruders are designed to blend, mix, and compound materials efficiently, enabling manufacturers to produce high-quality plastic products. Understanding the operational principles and advantages of compounding twin screw extruders can significantly enhance production processes

2025/09

The PLA sheet extrusion line is an advanced facility specifically designed for producing polylactic acid (PLA) sheet, playing a vital role in the processing of environmentally friendly materials.

2025/09

Counter Rotating Twin Screw Extruders: The Ultimate Guide for New Manufacturers

Counter Rotating Twin Screw Extruders: The Ultimate Guide for New Manufacturers Table of Contents 1. Introduction to Counter Rotating Twin Screw Extruders 2. Benefits of Counter Rotating Twin Screw Extruders 3. Working Principle of Counter Rotating Twin Screw Extruders 4. Applications of Counter Rotating Twin Screw Extruders 5. Key Components of Counter Rotating Twin Screw Extruders 6

2025/09

Understanding the Small Twin Screw Extruder: A Key Player in Plastic Processing

The small twin screw extruder is a specialized type of extrusion machine widely used in the manufacturing and processing of plastics. Unlike single screw extruders, which utilize a single helical screw for material transportation and melting, twin screw extruders feature two intermeshing screws that rotate synchronously. This design allows for enhanced mixing, compounding, and processing of materi

2025/09

A Comprehensive Guide to Twin Screw Extruder Operation and Maintenance Table of Contents 1. Introduction to Twin Screw Extruders 2. Understanding Twin Screw Extruders 2.1 Mechanical Design and Functionality 2.2 Types of Twin Screw Extruders 3. Operation of Twin Screw Extruders 3.1 Set Up and Startup Procedures

RELATED INFORMATION

Understanding the Mechanics of PET Single Screw Extruders: A Comprehensive Guide

Understanding the Mechanics of PET Single Screw Extruders Introduction to PET Single Screw Extruders PET single screw extruders are pivotal in the plastic manufacturing industry. These machines play a crucial role in converting raw PET pellets into a variety of products, ranging from bottles to fibers. Understanding their mechanics is essential for maximizing efficiency and output quality in man

Understanding Twin Screw Compounders: Enhancing Plastic Processing Efficiency

Twin screw compounders are essential machines in the plastic processing industry, particularly in the manufacturing of polymers and composites. These sophisticated devices are designed to melt, mix, and compound plastic materials efficiently. Their unique configuration, featuring two intermeshing screws, allows for improved material handling and processing capabilities compared to single screw ext