2025/09

Why Efficiency Matters in PET Extrusion Sheet Line Operations

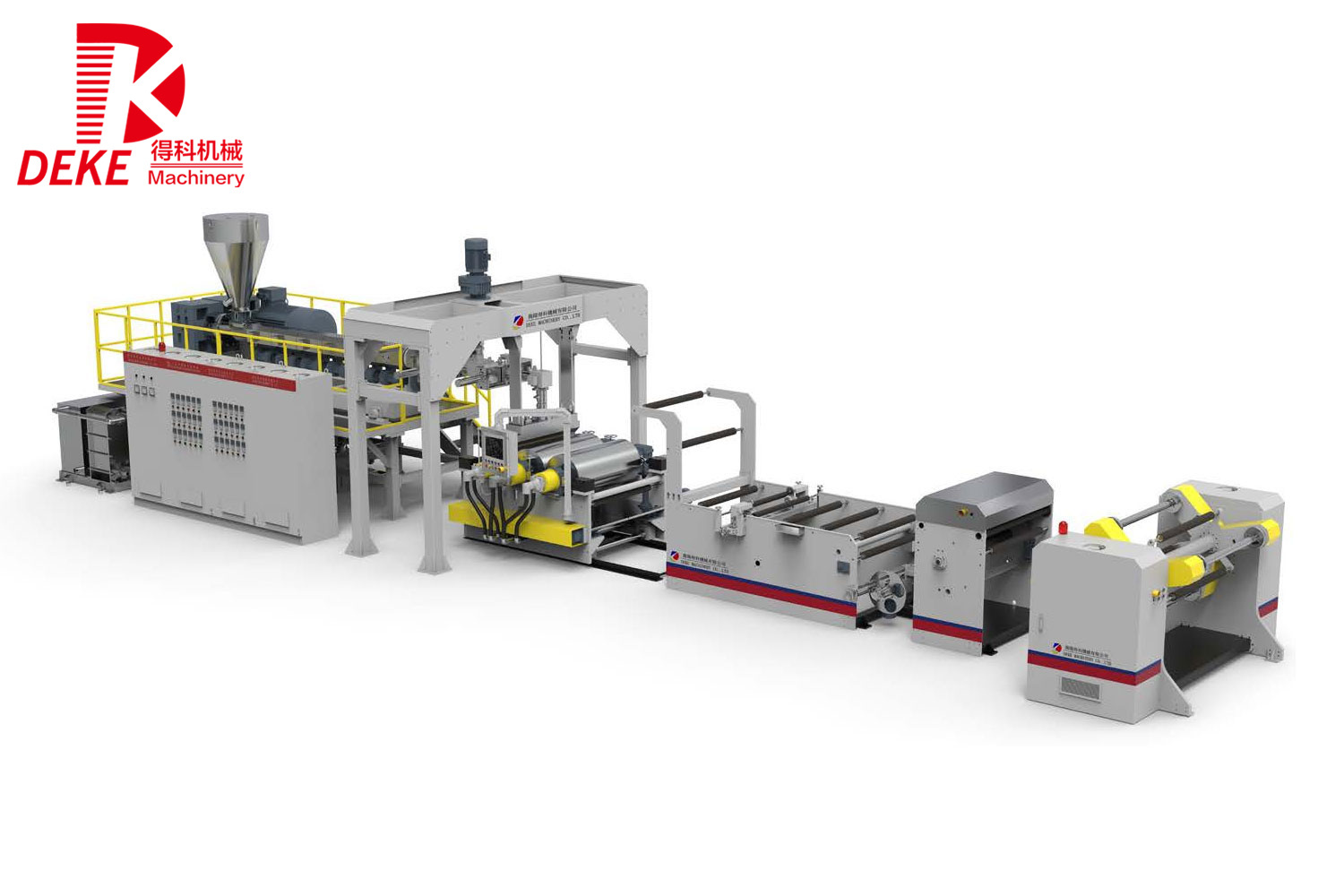

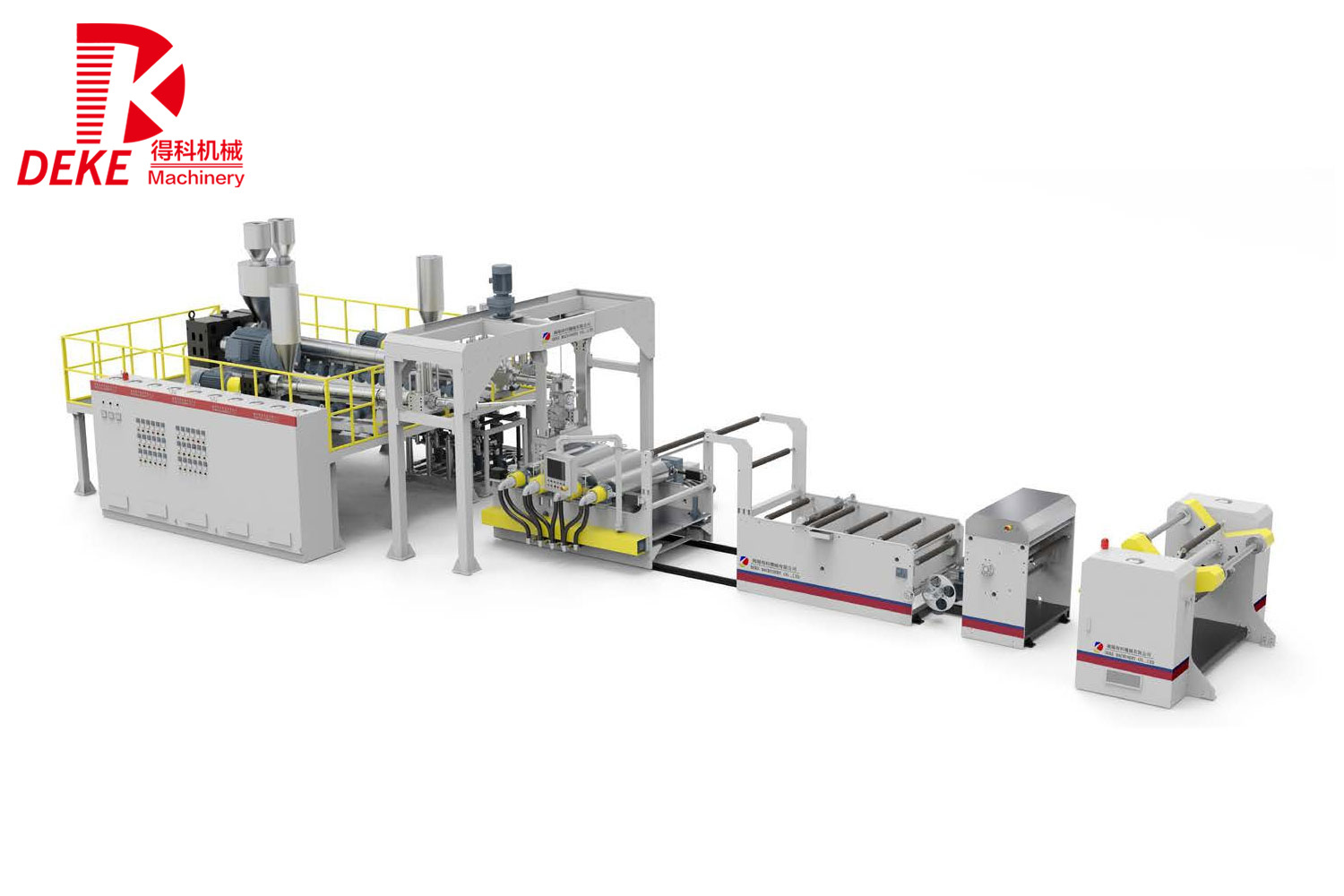

Why Efficiency Matters in PET Extrusion Sheet Line Operations Understanding PET Extrusion: An Overview The production of polyethylene terephthalate (PET) sheets has become increasingly important in various industries, including packaging, automotive, and construction. PET extrusion is a process that converts raw PET resin into usable sheets through a series of steps involving heat, pressure, and m

2025/09

Understanding the PLA Sheet Extruder Series: Key Insights for Professionals in Plastic Processing

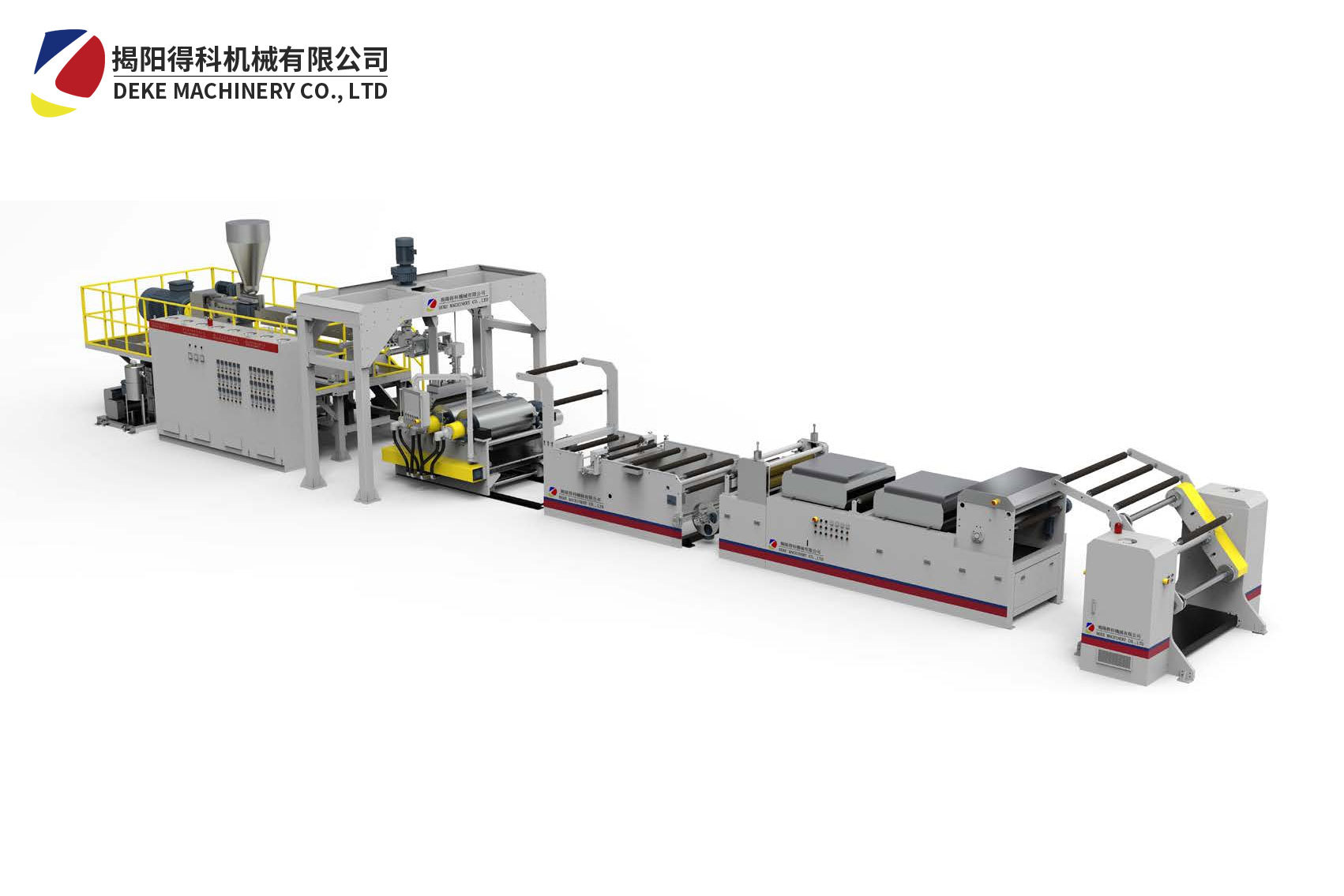

The PLA (Polylactic Acid) Sheet Extruder Series represents a significant advancement in the field of plastic processing machinery, tailored specifically for producing sheets from bioplastics. PLA is derived from renewable resources, making it a popular choice for manufacturers aiming to reduce their environmental footprint. Understanding the workings and benefits of the PLA Sheet Extruder Series i

2025/09

Unlocking Efficiency: The Role of Conical Extruders in Plastic Processing

Unlocking Efficiency: The Role of Conical Extruders in Plastic Processing Table of Contents 1. Introduction to Conical Extruders 2. Understanding Conical Extruders 3. Benefits of Conical Extruders in Plastic Processing 4. Applications of Conical Extruders 5. Conical Extruders vs. Parallel Extruders 6. Key Design Features of Conical Extruders 7. Maintenance Tips for Con

2025/09

Understanding Twin Screw Compounding Machines: Enhancing Plastic Processing Efficiency

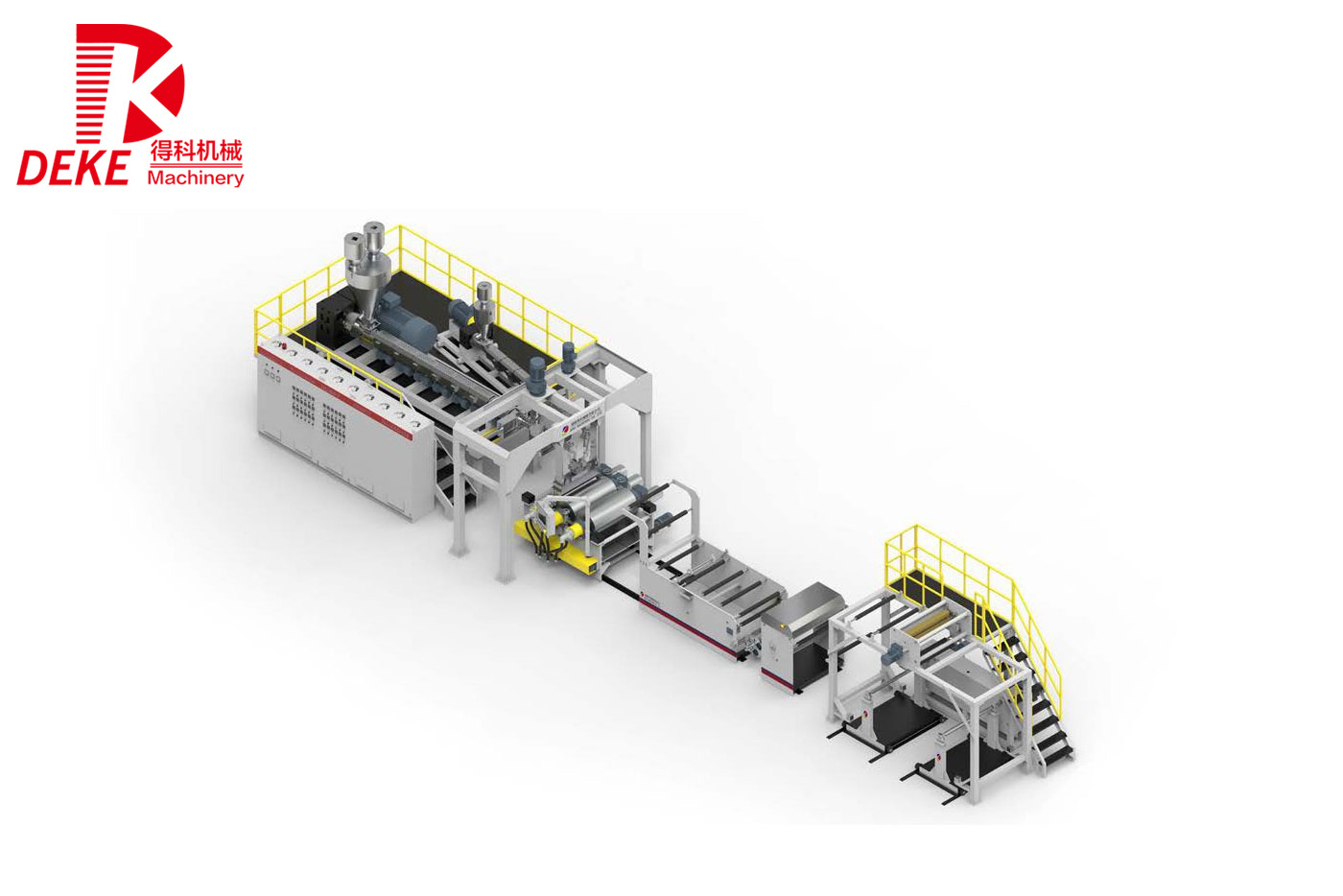

Twin screw compounding machines are advanced processing equipment widely used in the plastic manufacturing industry. Unlike traditional single screw extruders, these machines consist of two intermeshing screws that rotate in the same direction or opposite directions. This unique design offers several advantages, particularly in the compounding of polymers, additives, and other materials. One of th

2025/09

Optimizing Efficiency: Key Factors Influencing Twin Screw Roller Head Extruders

Factors Influencing the Efficiency of Twin Screw Roller Head Extruders Introduction to Twin Screw Roller Head Extruders Twin screw roller head extruders have emerged as a cornerstone in the manufacturing sector, particularly for processing plastics. This advanced technology is essential for producing a wide array of products, including films, sheets, and various molded components. Understanding

2025/09

Maximizing Efficiency with EVOH High Barrier Sheet Extruders: A Comprehensive Guide

In the world of plastic processing machinery, EVOH (Ethylene Vinyl Alcohol) high barrier sheet extruders play a crucial role in meeting the increasing demand for high-performance packaging materials. These extruders are specifically designed to produce sheets that offer exceptional barrier properties, making them ideal for a variety of applications such as food packaging, medical supplies, and oth

2025/09

Common Challenges in HIPS Sheet Extrusion and Effective Solutions

Common Challenges in HIPS Sheet Extrusion and Effective Solutions Introduction to HIPS Sheet Extrusion High Impact Polystyrene (HIPS) is a popular thermoplastic used in various applications, particularly in the production of sheets. The extrusion process for HIPS sheets involves heating the material until it becomes pliable, then forcing it through a die to create sheets of specified thickness.

2025/09

Exploring the Benefits and Applications of HDPE Sheet Extruders

High-Density Polyethylene (HDPE) sheet extruders play a pivotal role in the manufacturing and processing of plastic materials, particularly in the production of durable and versatile HDPE sheets. Understanding the function and benefits of HDPE sheet extruders is essential for professionals in the plastic processing machinery sector. HDPE, known for its high strength-to-density ratio, is widely uti

2025/09

Maximizing Efficiency with Advanced HDPE Sheet Extrusion Machinery

Maximizing Efficiency with Advanced HDPE Sheet Extrusion Machinery Table of Contents Introduction to HDPE Sheet Extrusion Understanding HDPE and Its Applications Benefits of HDPE Sheet Extrusion Technology Features of Advanced HDPE Sheet Extrusion Machinery Strategies for Maximizing Efficiency in HDPE Extrusion Importance of Quality Control in HDPE Production Case Stud

2025/09

Understanding PE Foam Sheet Extruders: A Key Component in Plastic Processing

Polyethylene (PE) foam sheets have become an integral part of various industries, serving as lightweight, durable, and versatile materials for packaging, insulation, and cushioning applications. The production of these foam sheets heavily relies on specialized equipment known as PE foam sheet extruders. Understanding how these machines operate and their significance in plastic processing is essent

RELATED INFORMATION

Understanding the Advantages of PET Twin Screw Extruders in Plastic Manufacturing

The PET twin screw extruder is a vital piece of equipment in the plastic processing industry, particularly for those working with polyethylene terephthalate (PET). This type of extruder offers several advantages that can significantly improve manufacturing efficiency and product quality. One of the primary benefits of PET twin screw extruders is their high mixing capability. The design of twin scr

Understanding the Mechanics of PET Single Screw Extruders: A Comprehensive Guide

Understanding the Mechanics of PET Single Screw Extruders Introduction to PET Single Screw Extruders PET single screw extruders are pivotal in the plastic manufacturing industry. These machines play a crucial role in converting raw PET pellets into a variety of products, ranging from bottles to fibers. Understanding their mechanics is essential for maximizing efficiency and output quality in man