2025/09

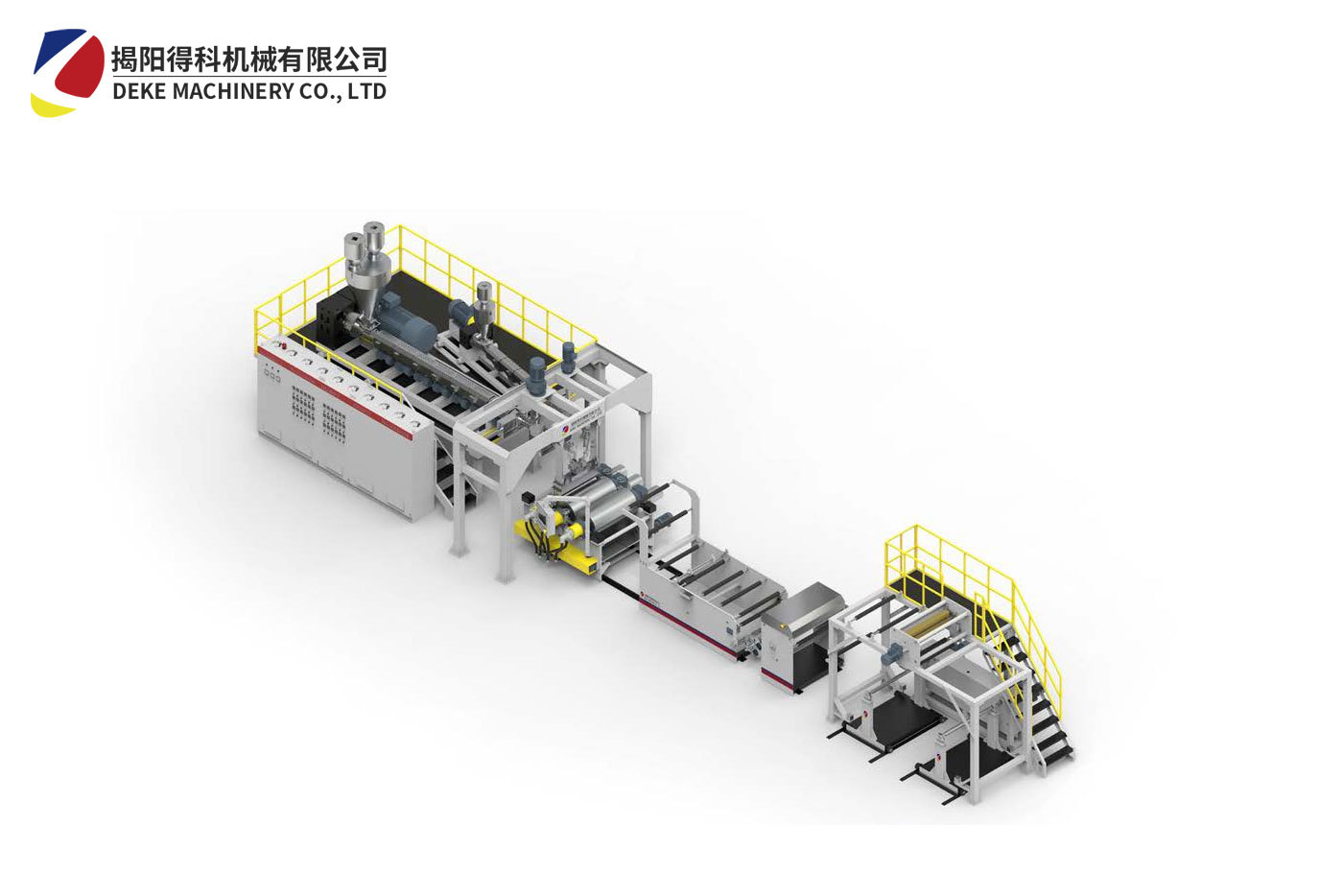

Choosing the Right Polycarbonate Sheet Extruder for Your Business Needs

Choosing the Right Polycarbonate Sheet Extruder for Your Business Needs When it comes to manufacturing polycarbonate sheets, selecting the right extruder is critical for operational efficiency, product quality, and overall business success. In this detailed guide, we will explore the various factors to consider when choosing a polycarbonate sheet extruder, ensuring you make an informed decision th

2025/09

Unlocking the Potential of Twin Screw Compounding Machines in Plastic Processing

Twin screw compounding machines are advanced pieces of equipment widely used in the plastic processing sector, especially for compounding and mixing polymers. These machines utilize two intermeshing screws, which rotate in opposite directions, creating a high shear and intensive mixing environment. This innovative design enables efficient processing of various materials, including polymers, additi

2025/09

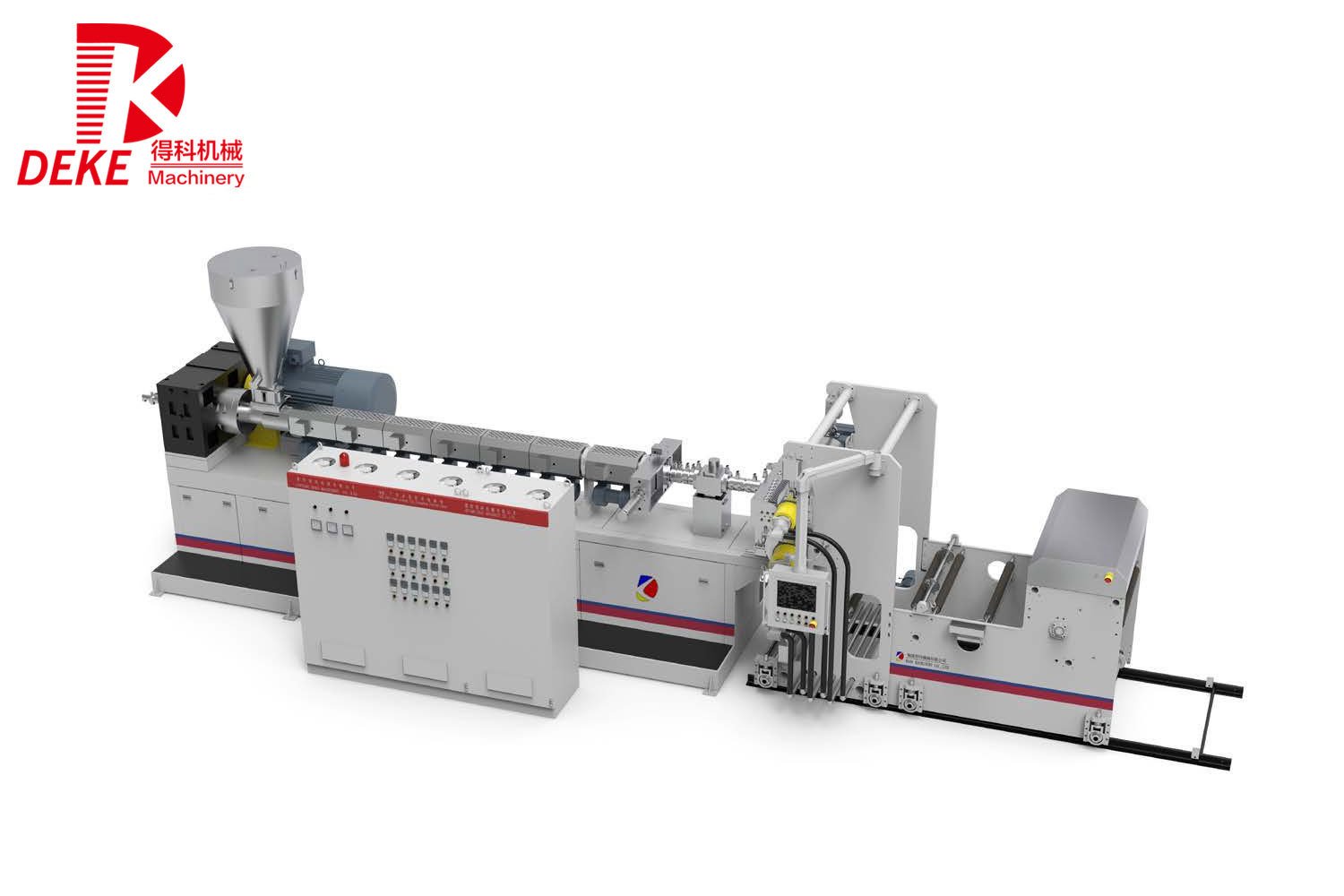

The Versatility of Twin Screw Roller Head Extruders in Custom Applications

The Versatility of Twin Screw Roller Head Extruders in Custom Applications Table of Contents Introduction to Twin Screw Roller Head Extruders What is a Twin Screw Extruder? How Do Twin Screw Extruders Work? Benefits of Using Twin Screw Extruders Customizable Designs and Applications Industries Utilizing Twin Screw Extruders Technological Advancements in Twin Screw Extr

2025/09

The Importance of EVOH High Barrier Sheet Extruders in Plastic Processing

EVOH (Ethylene Vinyl Alcohol) high barrier sheet extruders are becoming increasingly vital in the manufacturing and processing of plastic products, particularly in sectors requiring exceptional barrier properties. These extruders are designed to produce sheets that offer superior protection against gases, moisture, and other environmental factors that could compromise the integrity of packaged goo

2025/09

Choosing the Right HIPS Sheet Extruder for Your Manufacturing Needs

Choosing the Right HIPS Sheet Extruder for Your Manufacturing Needs Understanding HIPS Sheets and Their Applications HIPS (High-Impact Polystyrene) sheets are widely used in various industries due to their excellent toughness, impact resistance, and versatility. These sheets are commonly used for applications such as packaging, point-of-purchase displays, and even in the automotive sector. Underst

2025/09

Understanding HDPE Sheet Extruders: Key Insights for Plastic Processing

High-Density Polyethylene (HDPE) sheet extruders are specialized machines used to produce sheets from HDPE resin, a thermoplastic polymer known for its high strength-to-density ratio and impressive chemical resistance. The extrusion process involves melting the HDPE pellets and forcing them through a die to form continuous sheets of desired thickness and width. Understanding the workings and advan

2025/09

How HDPE Sheet Extrusion Enhances Sustainability in Plastic Manufacturing

How HDPE Sheet Extrusion Enhances Sustainability in Plastic Manufacturing Table of Contents 1. Introduction to HDPE and Its Importance in Manufacturing 2. What is HDPE? 3. Sustainability in Plastic Manufacturing 4. The HDPE Sheet Extrusion Process Explained 5. Benefits of HDPE Sheet Extrusion in Sustainable Practices 6. Applications of HDPE Sheets in Various Industries

2025/08

Understanding the PE Foam Sheet Extruder: Key Insights and Applications

Polyethylene (PE) foam is a popular material known for its lightweight, durability, and excellent cushioning properties. The PE foam sheet extruder is a specialized machine designed to produce sheets of PE foam through a process called extrusion. Understanding the workings and applications of this machine can provide valuable insights into its significance in the manufacturing and processing of pl

2025/08

A Deep Dive into the Mechanics of Polycarbonate Sheet Extruders

A Deep Dive into the Mechanics of Polycarbonate Sheet Extruders Polycarbonate sheets have become an essential material in various industries due to their unparalleled strength, transparency, and versatility. At the heart of producing these sheets lies the polycarbonate sheet extruder, a sophisticated machine designed to transform raw polycarbonate resin into usable sheets. In this article, we will

2025/08

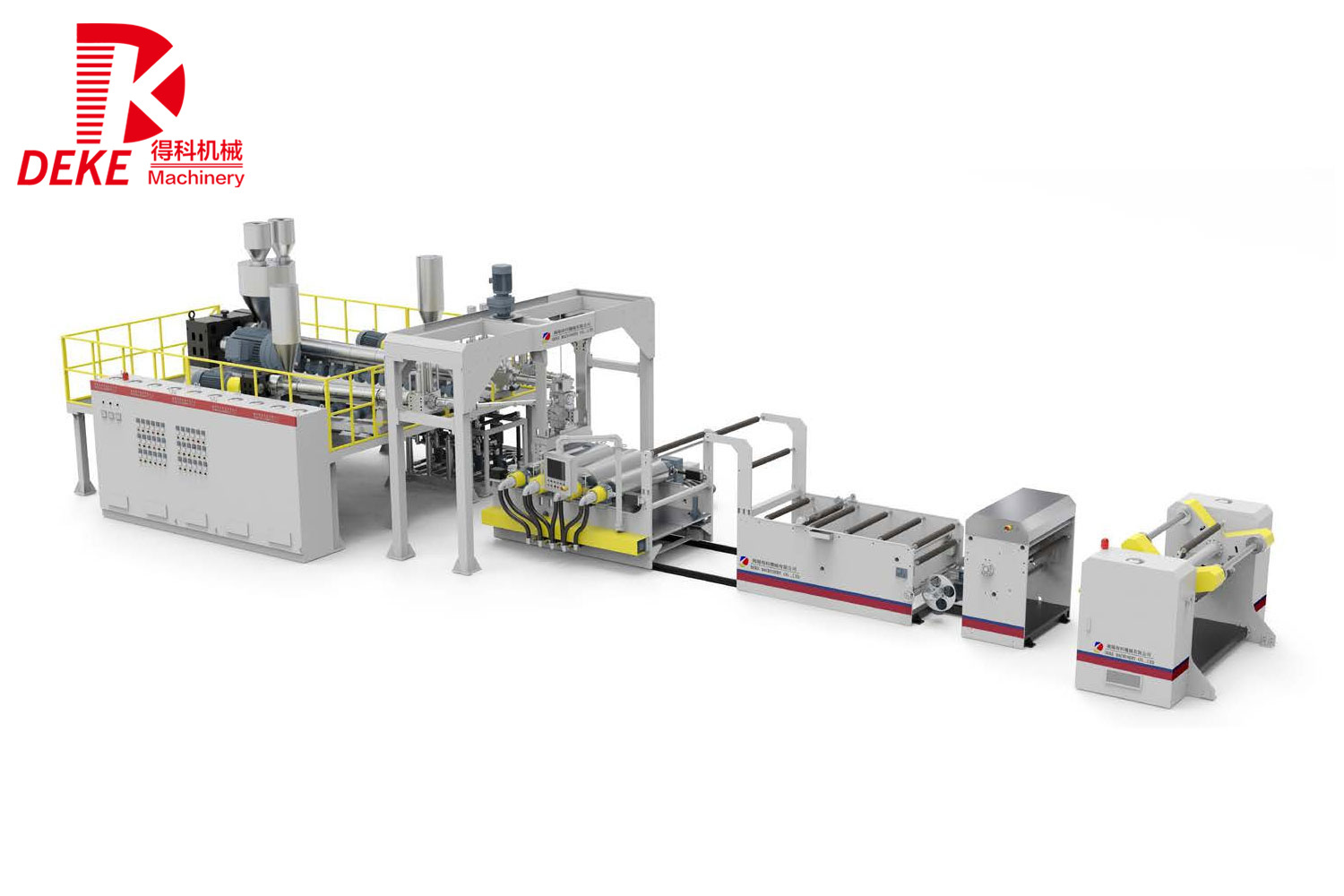

Understanding Twin Screw Compounding Machines: A Comprehensive Guide for Professionals

In the realm of plastics processing, the twin screw compounding machine plays a pivotal role. These machines are engineered to combine and process various materials, facilitating the production of high-quality plastic compounds. The unique design of twin screw extruders—featuring two intermeshing screws—enables efficient mixing, melting, and conveying of polymers and additives, making them an inva

RELATED INFORMATION

Understanding the Advantages of PET Twin Screw Extruders in Plastic Manufacturing

The PET twin screw extruder is a vital piece of equipment in the plastic processing industry, particularly for those working with polyethylene terephthalate (PET). This type of extruder offers several advantages that can significantly improve manufacturing efficiency and product quality. One of the primary benefits of PET twin screw extruders is their high mixing capability. The design of twin scr

Understanding the Mechanics of PET Single Screw Extruders: A Comprehensive Guide

Understanding the Mechanics of PET Single Screw Extruders Introduction to PET Single Screw Extruders PET single screw extruders are pivotal in the plastic manufacturing industry. These machines play a crucial role in converting raw PET pellets into a variety of products, ranging from bottles to fibers. Understanding their mechanics is essential for maximizing efficiency and output quality in man