Understanding PET Single Screw Extruders: Key Insights for Efficient Plastic Processing

2025-12

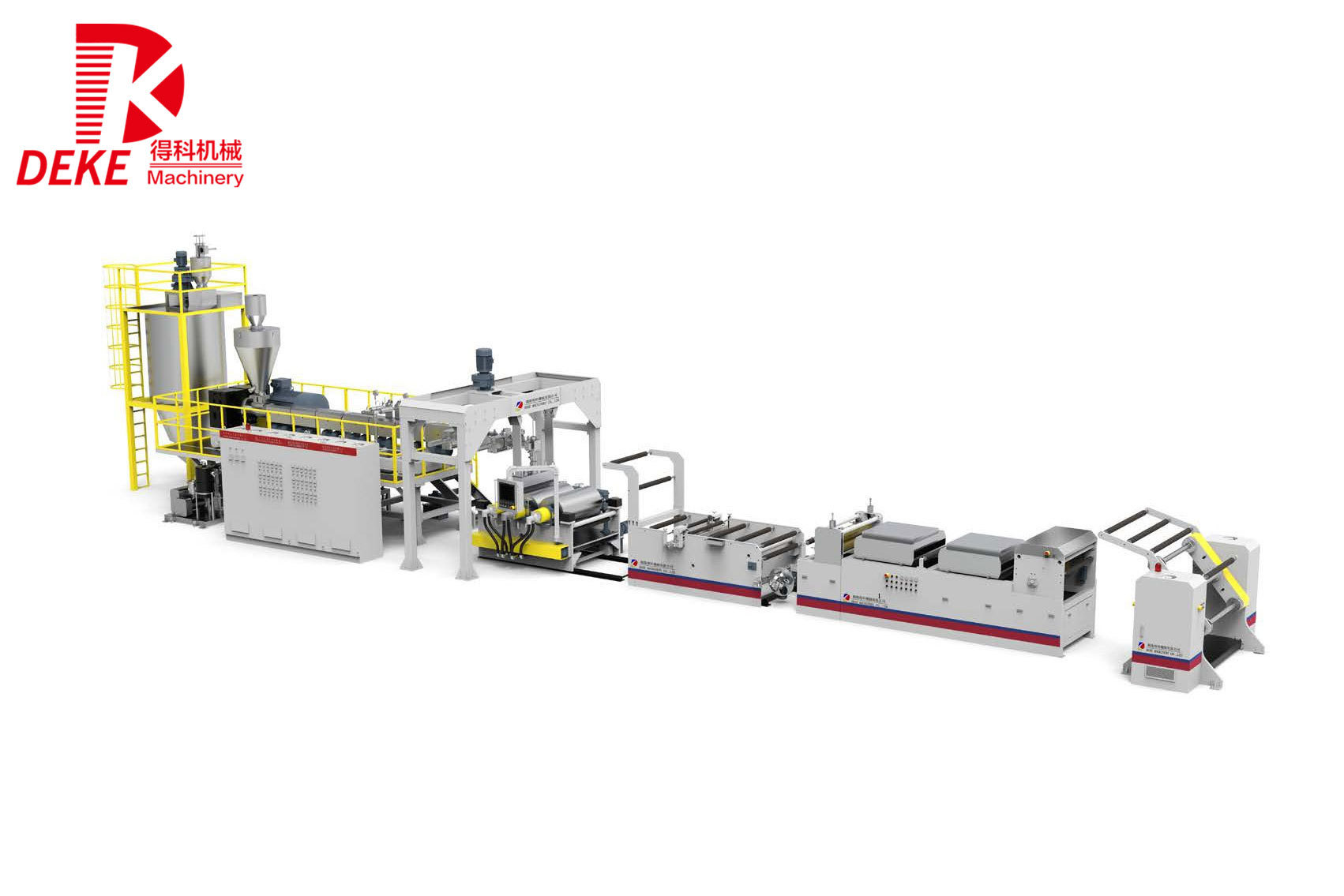

At its core, a PET single screw extruder operates by feeding raw PET pellets into a heated barrel where they are melted and conveyed through a screw mechanism. The single screw design allows for a continuous flow of material, ensuring consistent output and uniformity in the final product. The temperature control during the melting process is crucial, as it directly affects the viscosity and flow of the PET material. Therefore, maintaining the right temperature profile is essential for optimal processing.

One of the key advantages of using a PET single screw extruder is its versatility. It can be adapted for various applications, including film and sheet production, blow molding, and injection molding. This flexibility makes it an invaluable asset for manufacturers looking to expand their product range or improve existing offerings. Additionally, the ability to finely control the extrusion parameters allows for the production of high-quality products with specific characteristics tailored to customer needs.

Another significant factor to consider is the energy efficiency of PET single screw extruders. Modern designs incorporate advanced technologies that reduce energy consumption while maintaining high output rates. This not only helps in minimizing operational costs but also contributes to a more sustainable manufacturing process, aligning with the growing emphasis on environmental responsibility in the industry.

Maintenance and operational practices are also crucial for maximizing the performance of PET single screw extruders. Regular inspections, cleaning, and timely replacement of worn-out components can prevent production downtime and extend the lifespan of the machinery. Training operators to understand the nuances of the machine, including troubleshooting common issues, can further enhance productivity and reduce errors during processing.

In conclusion, the PET single screw extruder represents a cornerstone technology in the plastic processing industry. By understanding its operation, applications, and maintenance needs, manufacturers can leverage its capabilities to improve efficiency and product quality. Keeping abreast of the latest advancements in extruder technology will ensure that your operations remain competitive and responsive to market demands, paving the way for sustainable growth in your business.

RELATED INFORMATION

How PET Sheet Extruders Revolutionize Plastic Processing Machinery

How PET Sheet Extruders Revolutionize Plastic Processing Machinery Table of Contents Introduction to PET Sheet Extruders Understanding Plastic Processing Machinery The Technology Behind PET Sheet Extruders Advantages of Using PET Sheet Extruders Sustainability in Plastic Manufacturing Applications of PET Sheets in Various Industries Future Trends in PET Sheet Extrusion

PET sheet extruder machines play a crucial role in the field of plastic processing, specifically in the production of polyethylene terephthalate (PET) sheets. These machines are designed to melt and extrude PET resin into sheets of varying thickness, which are then used in a variety of applications such as packaging, construction, and consumer goods. Understanding how these machines work and their