2024/09

Advantages of biodegradable extruder

The advantages of biodegradable extruders are mainly reflected in environmental protection, high-efficiency output, precise control, customized functions, easy operation and intelligent control.

2024/09

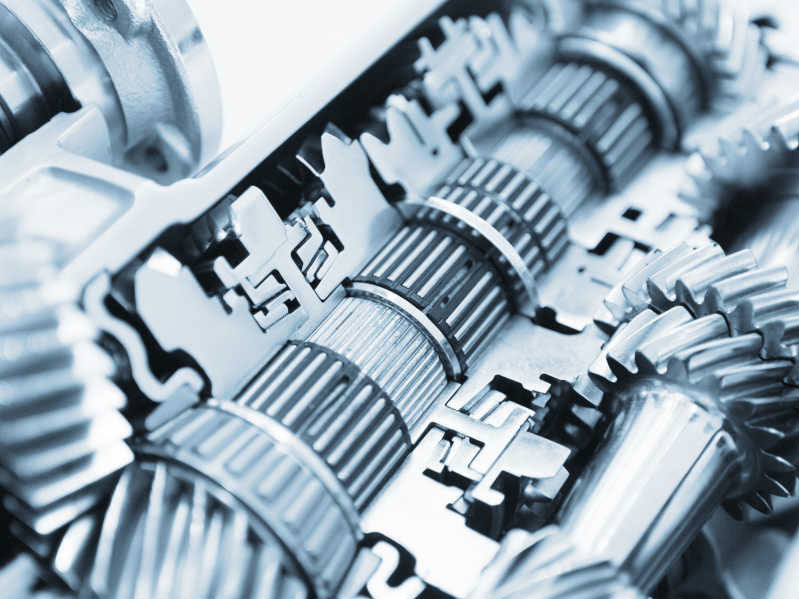

Working principle of twin screw extruder

The twin-screw extruder not only has the characteristics of a single-screw extruder, but also has the advantages of feeding and turning, stable extrusion, and convenient exhaust. Widely used in the production and processing of extruded products.

2024/09

Why Extruders Need Co-Extrusion

Extruders need to be co-extruded mainly because co-extrusion technology can produce multi-layer composite products with multiple functions and characteristics, which have a wide range of applications in many fields.

2024/09

Difference Between Twin Screw Extruder and Single Screw Extruder

In the single screw extruder, the friction drag is in the solid conveying section, and the viscous drag is in the melt conveying section. The tribological properties of the solid material and the viscosity of the molten material determine the conveying behavior.

2024/09

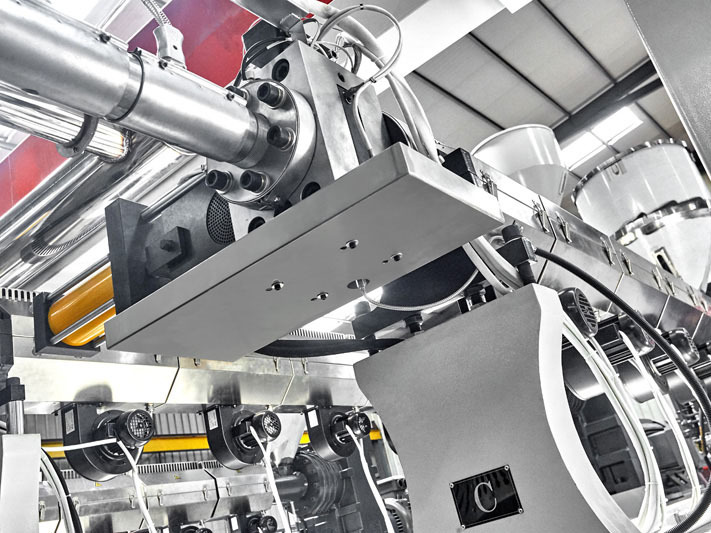

Common maintenance methods for extruders

Extruder is a commonly used plastic processing equipment. Regular maintenance can extend the service life of the equipment, improve production efficiency and reduce the occurrence of failures.

2024/09

What is the reason why the main motor of the single screw extruder cannot be started and its treatment method? The following small series respectively expounds the reason why the main machine cannot be started and its treatment method.

2024/09

What is the role of the extruder

The main function of the extruder is to make the material fully plasticized and evenly mixed by the pressure and shear force generated by the rotation of the screw, and then molded through the die to produce various plastic products.

2024/09

The function principle and future research direction of twin screw extruder

The twin-screw extruder not only has the characteristics of a single-screw extruder, but also has the advantages of feeding and turning, stable extrusion, and convenient exhaust. Widely used in the production and processing of extruded products.

2024/09

Common application scenarios: where are biodegradable plastics used?

Since the release of the "plastic restriction order" in 2020, the market for biodegradable plastics has grown rapidly. Under the promotion and publicity of biodegradable plastics, the concept of "degradable" equivalent to "environmental protection" began to be known and accepted by the public.

RELATED INFORMATION

Why Choose Conical Twin Screw for Your Next Extrusion Project?

Why Choose Conical Twin Screw for Your Next Extrusion Project? Understanding Extrusion Technology In the realm of **plastic processing**, extrusion is an essential manufacturing technique that transforms raw plastic materials into usable products. The **extrusion process** involves forcing molten plastic through a die to create continuous shapes like sheets, films, and profiles. With advancements

Understanding the Advantages of Counter Rotating Twin Screw Extruders for Plastic Processing

Counter rotating twin screw extruders are pivotal in the plastic processing industry, recognized for their versatility and efficiency. Unlike single screw extruders, twin screw extruders feature two intermeshing screws that rotate in opposite directions. This design allows for enhanced material handling and processing capabilities, making them suitable for a wide array of applications. One of the