2025/12

Exploring the Benefits and Applications of Small Twin Screw Extruders in Plastic Processing

In the realm of plastic processing machinery, the small twin screw extruder stands out as a versatile and efficient solution for various applications. This type of extruder is designed with two intermeshing screws that work in tandem to facilitate the processing of a wide range of materials, making it a valuable asset in modern manufacturing environments. One of the primary advantages of small twi

2025/12

Exploring the Versatility of PET Extrusion Sheet Lines Across Industries

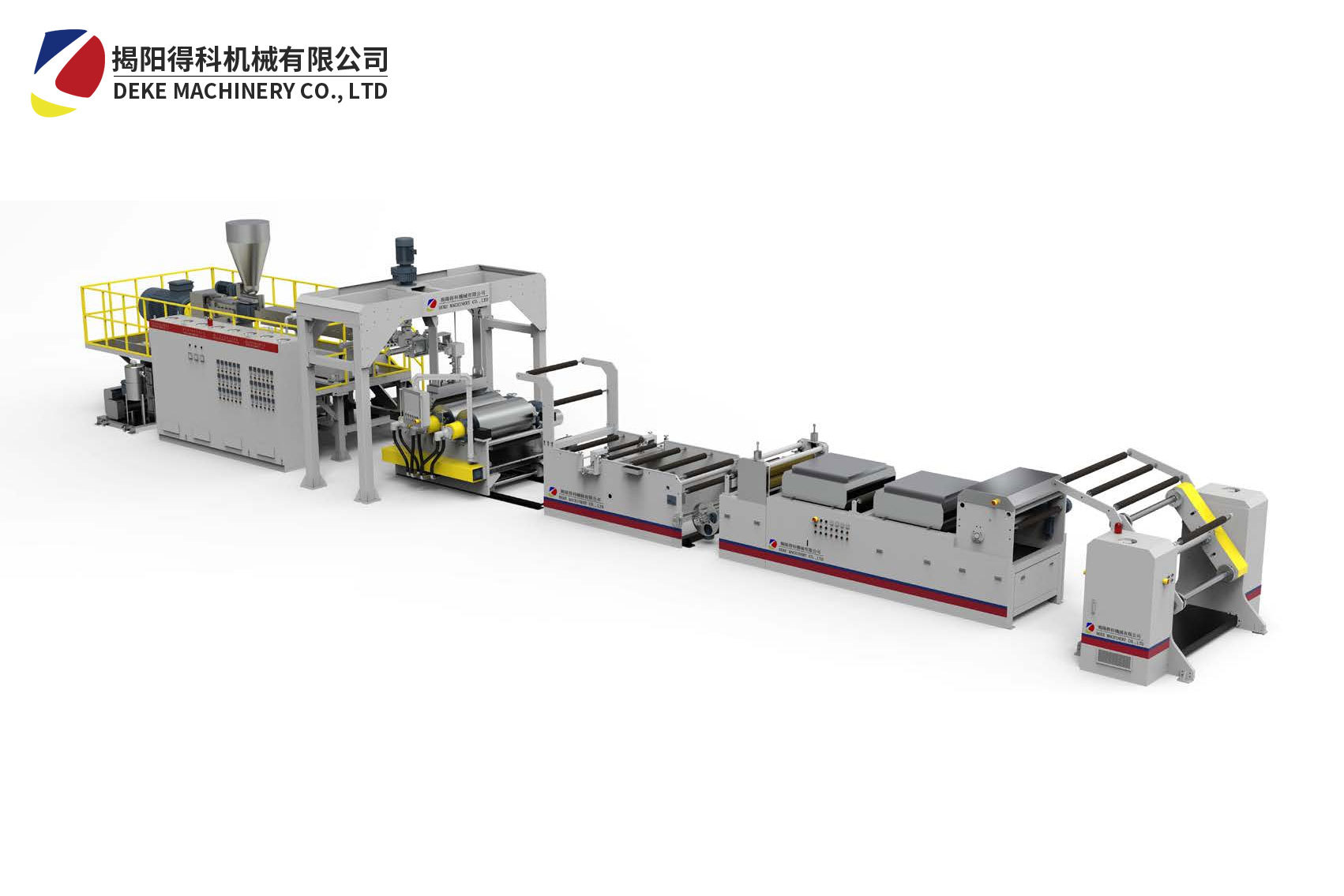

Exploring the Versatility of PET Extrusion Sheet Lines Across Industries Introduction to PET Extrusion Technology In the rapidly evolving landscape of manufacturing, the focus has shifted towards materials that provide durability, flexibility, and sustainability. **Polyethylene Terephthalate (PET)** has emerged as a frontrunner in this regard, particularly through its application in **extrusion sh

2025/12

Understanding the Benefits and Applications of PET Single Screw Extruders

In the realm of plastic processing machinery, PET single screw extruders have gained significant traction due to their efficiency and versatility. These machines are specifically designed to process Polyethylene Terephthalate (PET), a widely used thermoplastic polymer known for its excellent mechanical properties and recyclability. Understanding the key features and benefits of PET single screw ex

2025/12

Top Trends in Plastic Extrusion: The Rise of PET Sheet Technology

Top Trends in Plastic Extrusion: The Rise of PET Sheet Technology Introduction to Plastic Extrusion and PET Sheets Plastic extrusion has become a cornerstone of modern manufacturing, enabling the production of diverse plastic products with high efficiency. Among the various materials processed, **Polyethylene Terephthalate** (PET) has gained significant traction, especially in the form of sheets.

2025/12

Unlocking the Potential of PET Twin Screw Extruders in Plastic Processing

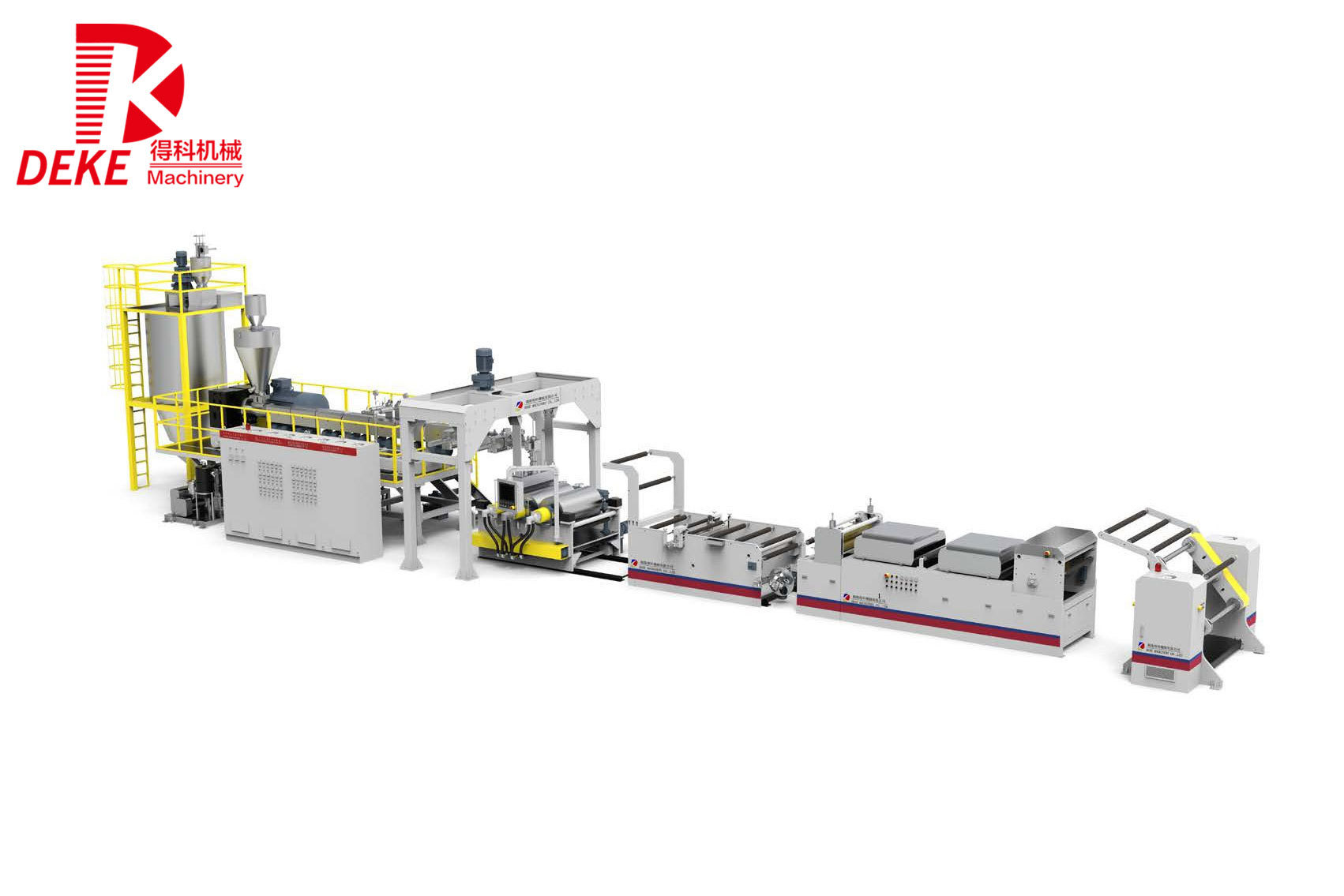

The PET twin screw extruder is a critical machine in the field of plastic processing, particularly known for its ability to handle a variety of polymer materials with precision and efficiency. This advanced piece of equipment utilizes two intermeshing screws to facilitate the melting, mixing, and pumping of thermoplastic materials. The design and operational capabilities of twin screw extruders ha

2025/12

Optimizing Your Production Line with Twin Screw Compounders: A Comprehensive Guide

Optimizing Your Production Line with Twin Screw Compounders: A Comprehensive Guide Introduction to Twin Screw Compounders The world of manufacturing is continuously evolving, and one of the key innovations in plastic processing technology is the twin screw compounder. This machine offers unparalleled advantages in mixing, extruding, and processing materials, making it an essential tool for optimiz

2025/12

Understanding the Role of PET Sheet Extruder in Plastic Processing

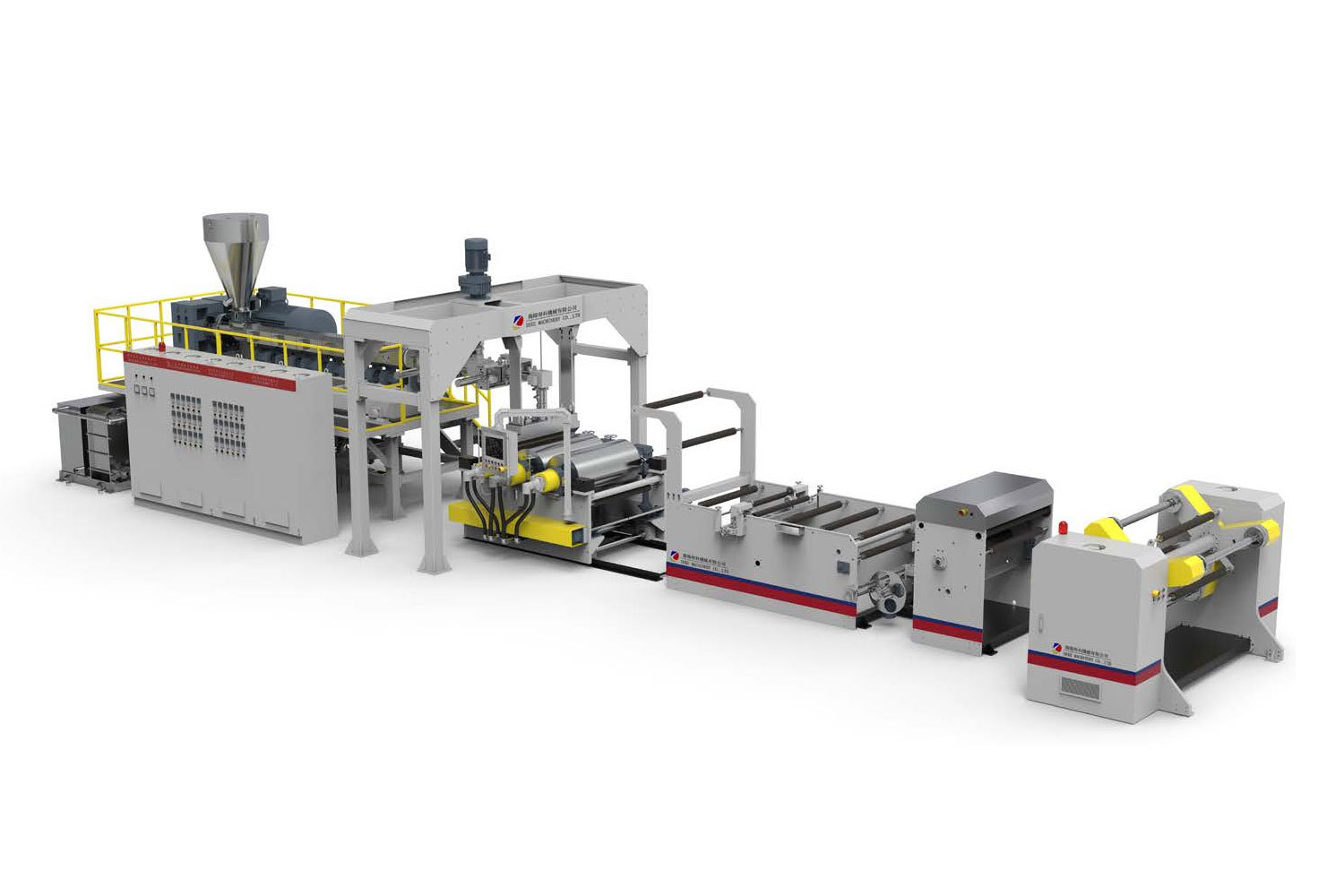

The PET sheet extruder plays a pivotal role in the plastic processing industry, particularly in the manufacturing of polyethylene terephthalate (PET) sheets. These sheets have a wide range of applications, including packaging, signage, and various industrial uses. Understanding the functionality of a PET sheet extruder can help businesses optimize their production processes and enhance product qua

2025/12

The Role of Automation in Modern PET Sheet Extruder Machines

The Role of Automation in Modern PET Sheet Extruder Machines The landscape of plastic processing has seen a dramatic transformation over recent years, particularly with the integration of automation in manufacturing processes. One of the most prominent advancements has been in **Polyethylene Terephthalate (PET) sheet extruder machines**. These machines are vital in producing PET sheets used across

2025/12

Understanding the Advantages of PET Twin Screw Extruders in Plastic Manufacturing

The PET twin screw extruder is a vital piece of equipment in the plastic processing industry, particularly for those working with polyethylene terephthalate (PET). This type of extruder offers several advantages that can significantly improve manufacturing efficiency and product quality. One of the primary benefits of PET twin screw extruders is their high mixing capability. The design of twin scr

2025/12

Understanding the Mechanics of PET Single Screw Extruders: A Comprehensive Guide

Understanding the Mechanics of PET Single Screw Extruders Introduction to PET Single Screw Extruders PET single screw extruders are pivotal in the plastic manufacturing industry. These machines play a crucial role in converting raw PET pellets into a variety of products, ranging from bottles to fibers. Understanding their mechanics is essential for maximizing efficiency and output quality in man

RELATED INFORMATION

Why Choose Conical Twin Screw for Your Next Extrusion Project?

Why Choose Conical Twin Screw for Your Next Extrusion Project? Understanding Extrusion Technology In the realm of **plastic processing**, extrusion is an essential manufacturing technique that transforms raw plastic materials into usable products. The **extrusion process** involves forcing molten plastic through a die to create continuous shapes like sheets, films, and profiles. With advancements

Understanding the Advantages of Counter Rotating Twin Screw Extruders for Plastic Processing

Counter rotating twin screw extruders are pivotal in the plastic processing industry, recognized for their versatility and efficiency. Unlike single screw extruders, twin screw extruders feature two intermeshing screws that rotate in opposite directions. This design allows for enhanced material handling and processing capabilities, making them suitable for a wide array of applications. One of the