2025/12

Understanding Twin Screw Compounders: Enhancing Plastic Processing Efficiency

Twin screw compounders are essential machines in the plastic processing industry, particularly in the manufacturing of polymers and composites. These sophisticated devices are designed to melt, mix, and compound plastic materials efficiently. Their unique configuration, featuring two intermeshing screws, allows for improved material handling and processing capabilities compared to single screw ext

2025/12

How PET Sheet Extruders Revolutionize Plastic Processing Machinery

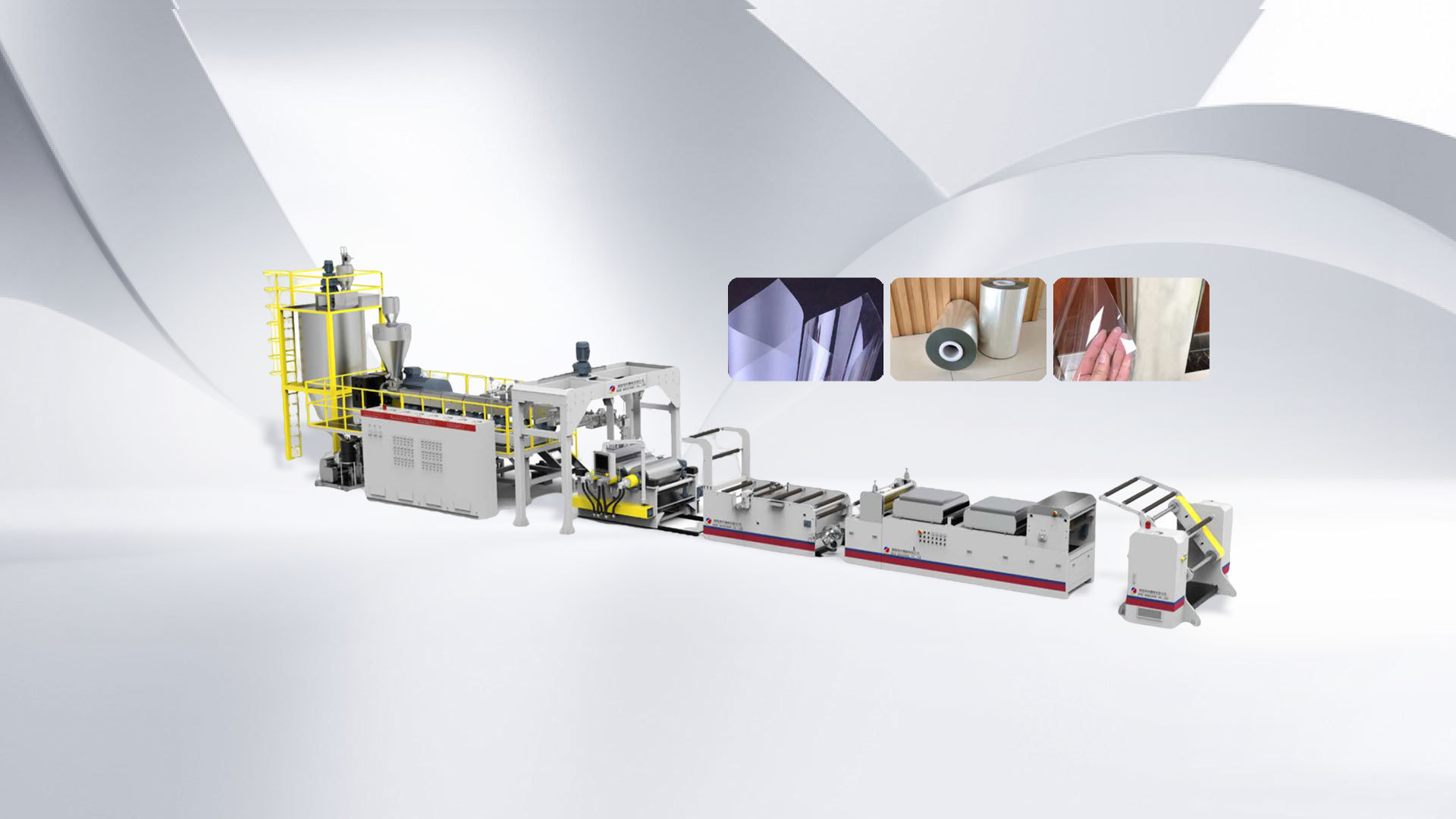

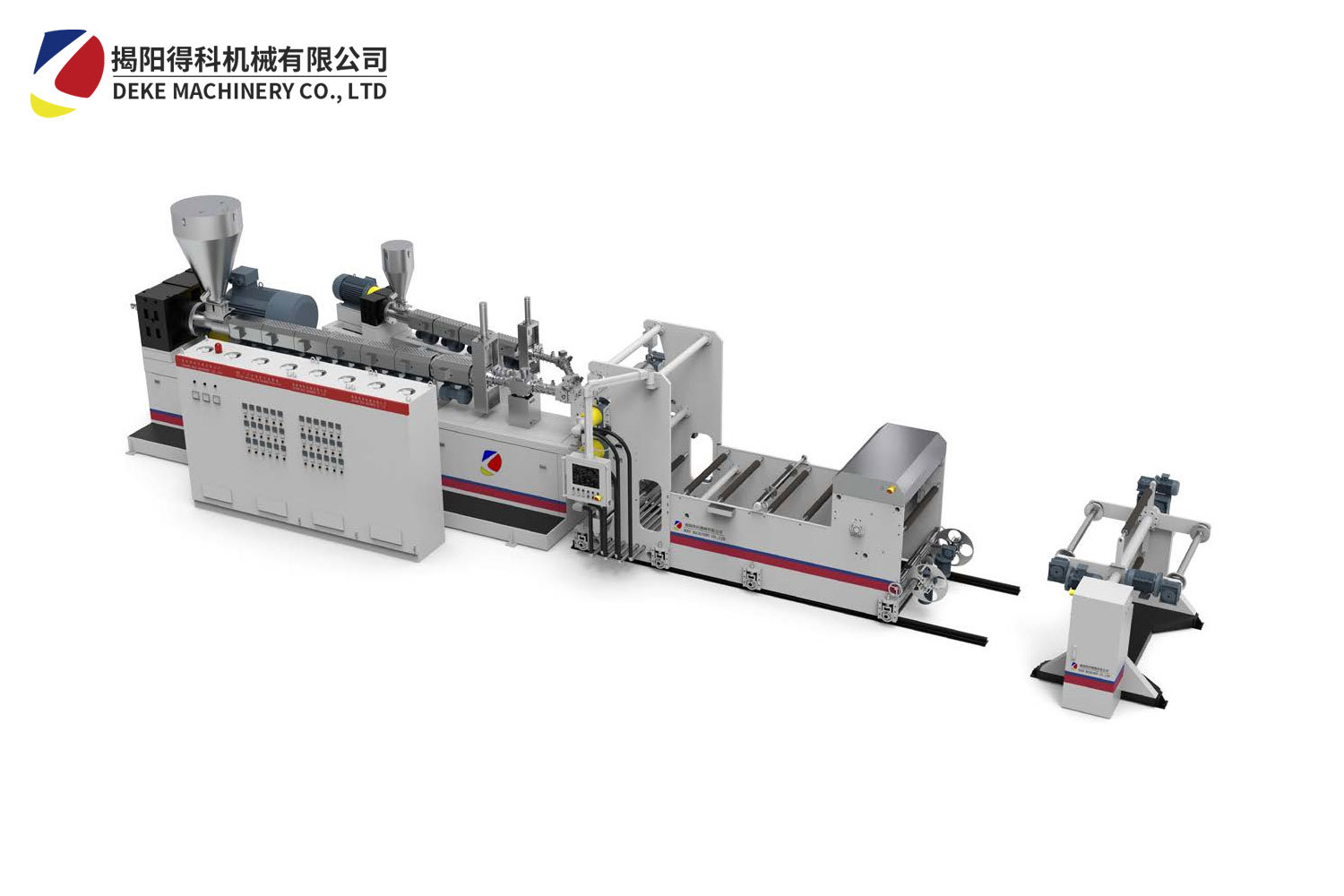

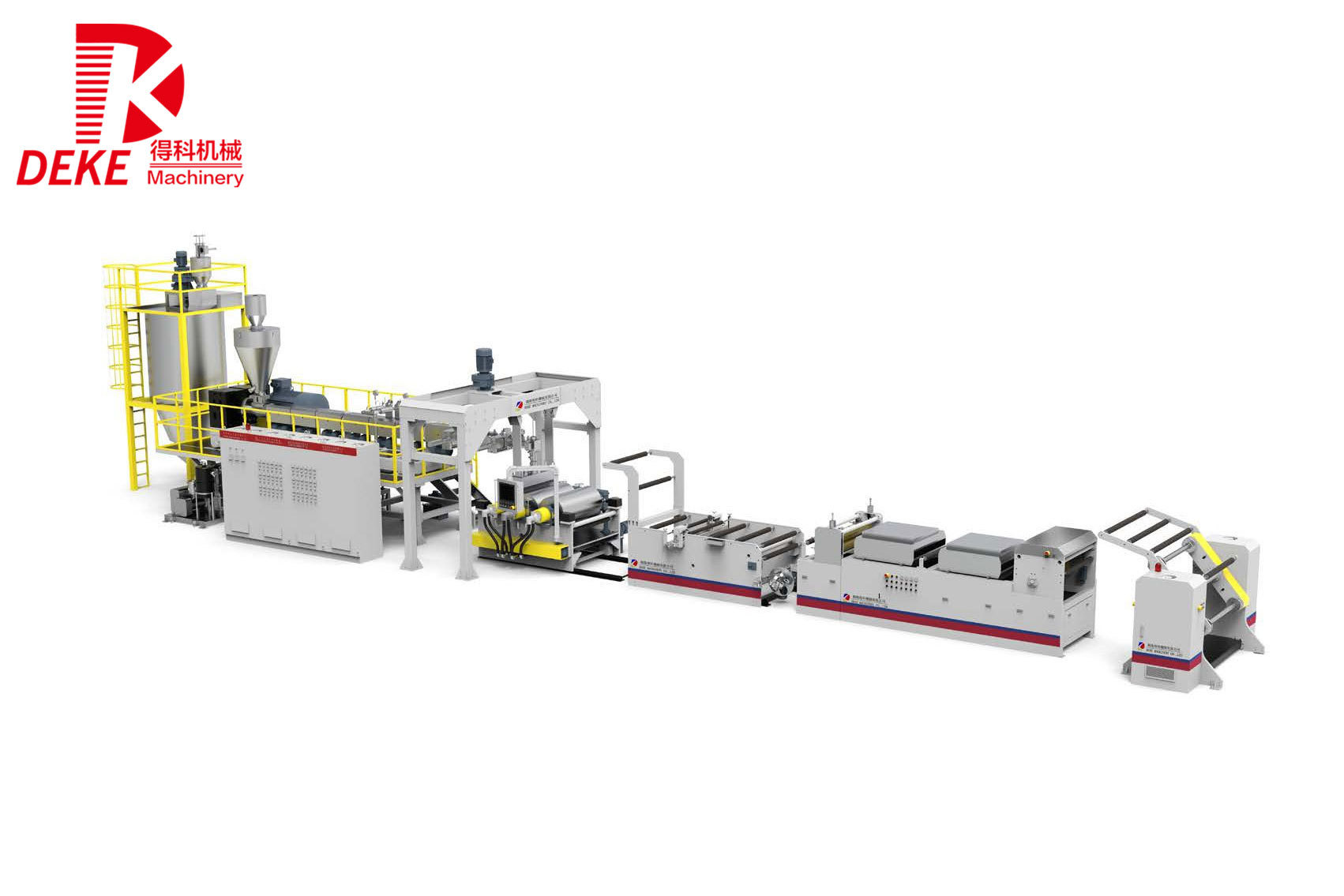

How PET Sheet Extruders Revolutionize Plastic Processing Machinery Table of Contents Introduction to PET Sheet Extruders Understanding Plastic Processing Machinery The Technology Behind PET Sheet Extruders Advantages of Using PET Sheet Extruders Sustainability in Plastic Manufacturing Applications of PET Sheets in Various Industries Future Trends in PET Sheet Extrusion

2025/12

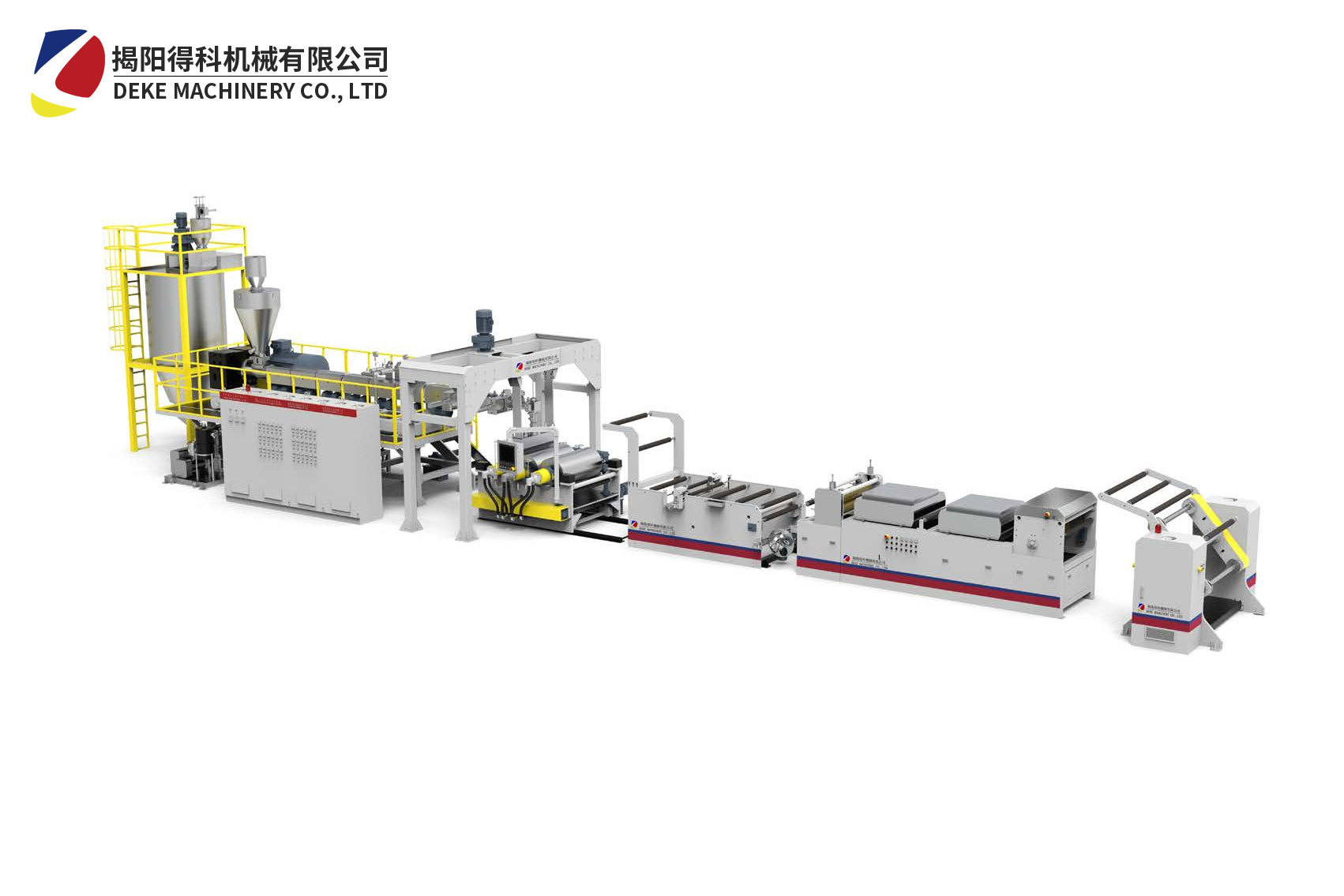

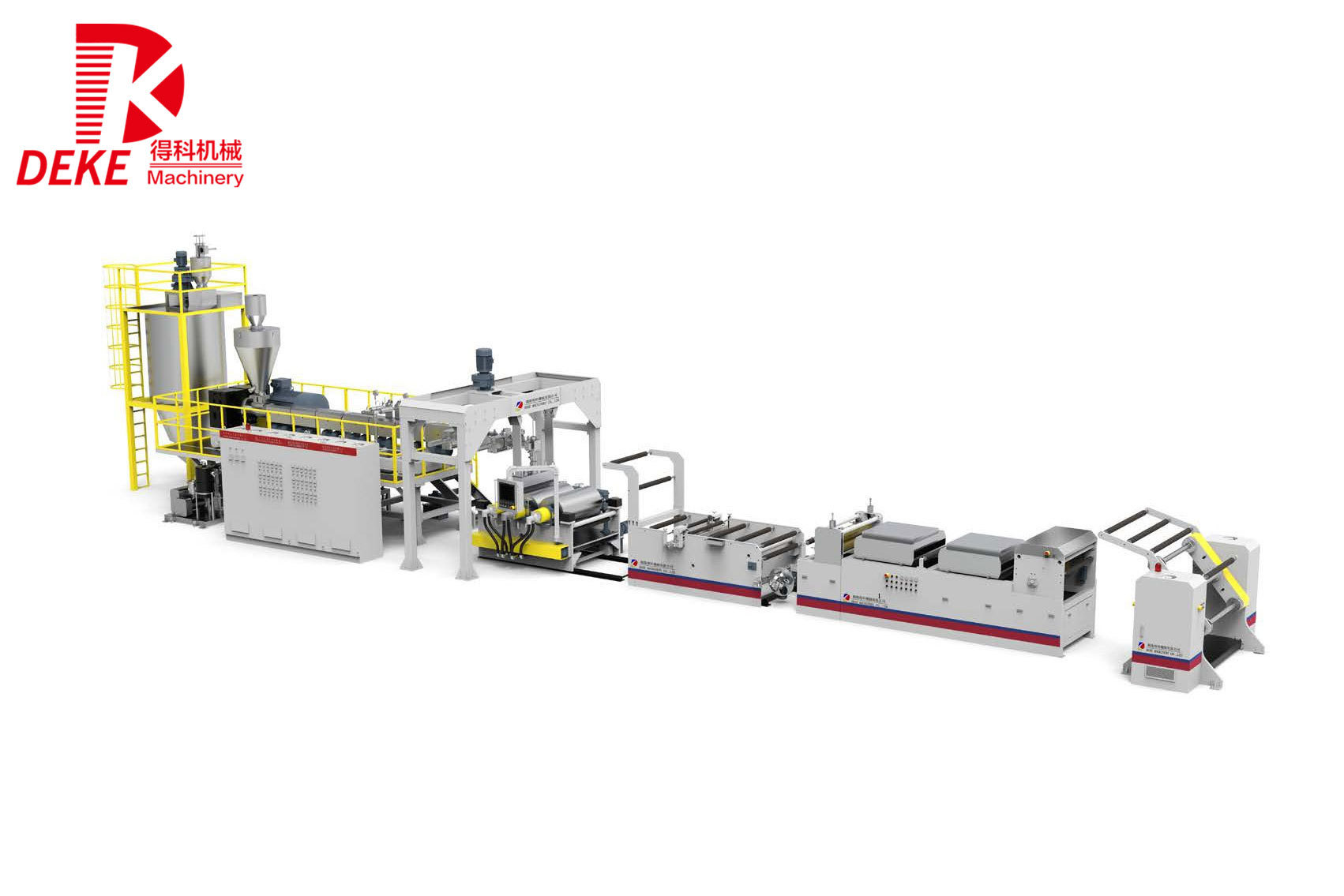

PET sheet extruder machines play a crucial role in the field of plastic processing, specifically in the production of polyethylene terephthalate (PET) sheets. These machines are designed to melt and extrude PET resin into sheets of varying thickness, which are then used in a variety of applications such as packaging, construction, and consumer goods. Understanding how these machines work and their

2025/12

Maximizing Output: The Science Behind PET Twin Screw Extruders

Maximizing Output: The Science Behind PET Twin Screw Extruders Table of Contents 1. Introduction to PET Twin Screw Extruders 2. Understanding PET Extrusion Process 3. Design Principles of Twin Screw Extruders 4. Operational Mechanics of PET Twin Screw Extruders 5. Strategies for Maximizing Output 6. Troubleshooting Common Issues in PET Extrusion 7. Future Trends in Extrusion Technology 8. Conclusi

2025/12

Understanding PET Single Screw Extruders: Key Insights for Efficient Plastic Processing

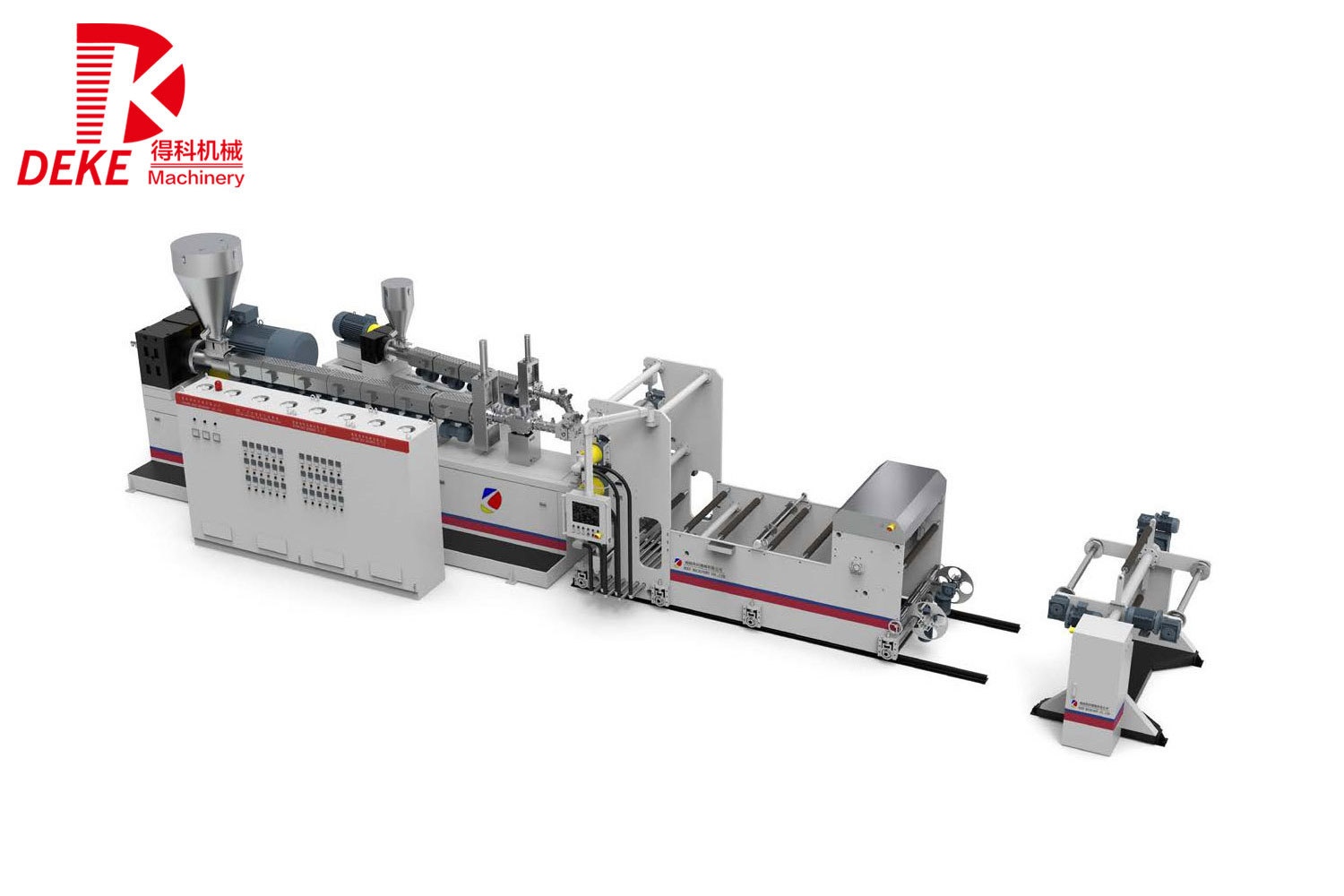

In the competitive landscape of plastic processing machinery, the PET single screw extruder stands out as a vital component for efficient production. This type of extruder is specifically designed for the processing of polyethylene terephthalate (PET), a thermoplastic polymer widely used in various industries. Understanding the intricacies of PET single screw extruders can significantly improve yo

2025/12

Unlocking the Potential of Twin Screw Compounders: A Comprehensive Guide to Advanced Material Processing Table of Contents 1. Introduction to Twin Screw Compounders 2. Understanding the Mechanism of Twin Screw Compounders 3. Key Applications of Twin Screw Compounders in Material Processing 4. Advantages of Using Twin Screw Compounders 5. Key Factors Influencing the Performance

2025/11

Understanding PET Sheet Extruders: Key Insights for Efficient Plastic Processing

PET sheet extruders are specialized machines designed to produce polyethylene terephthalate (PET) sheets through an extrusion process. This technology is vital in the manufacturing sector, particularly for producing rigid and flexible products used in packaging, automotive, and construction applications. Understanding the intricacies of PET sheet extruders can greatly enhance operational efficienc

2025/11

Key Factors to Consider When Purchasing a PET Sheet Extruder Machine

Key Factors to Consider When Purchasing a PET Sheet Extruder Machine Introduction to PET Sheet Extruder Machines The market for plastic processing machinery, particularly PET sheet extruders, has seen significant growth in recent years. These machines play a crucial role in the production of PET sheets, which are widely used in packaging, electronics, and automotive applications. When consider

2025/11

Unlocking Efficiency in Plastic Processing: The Role of PET Twin Screw Extruders

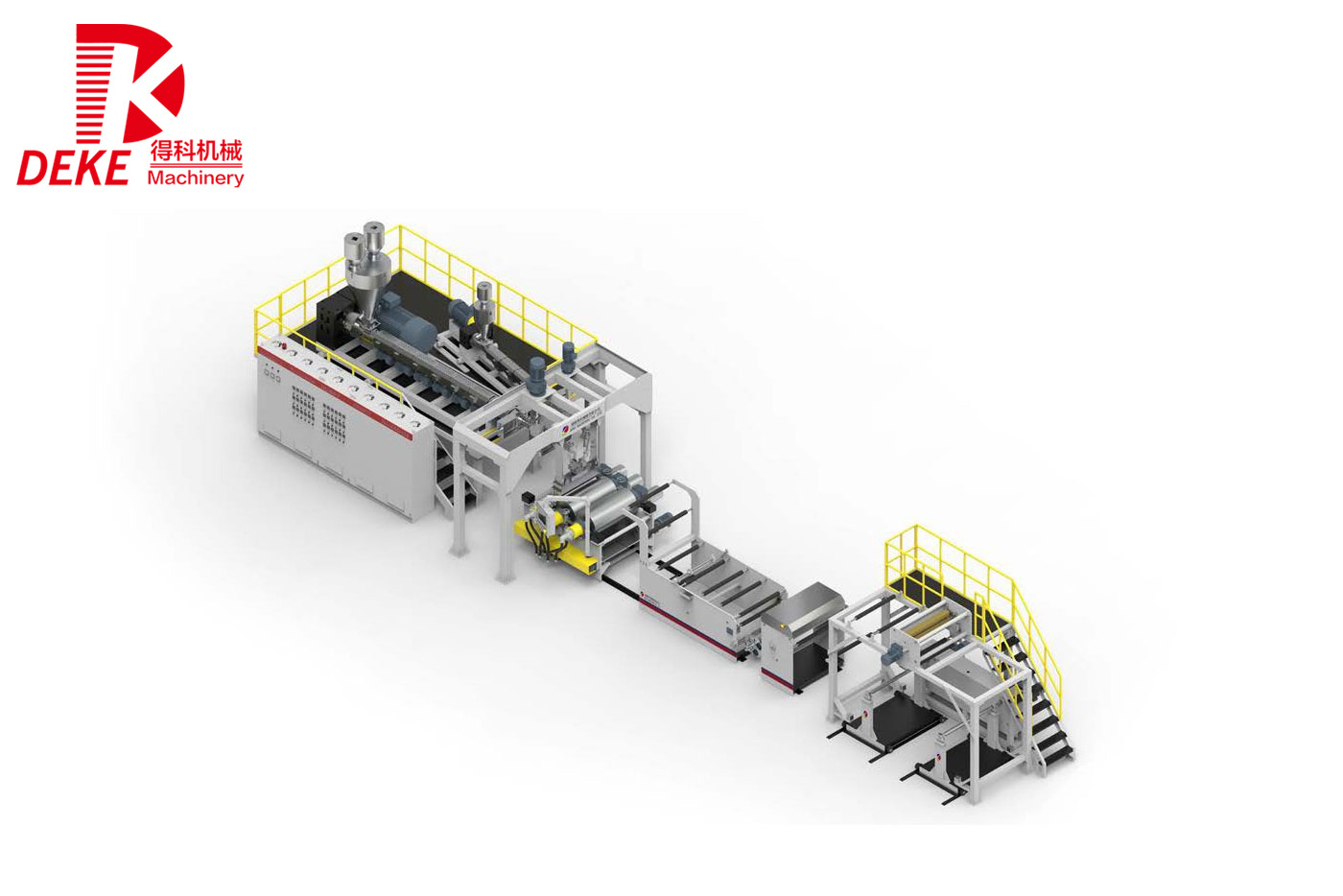

In the realm of plastic processing machinery, the PET twin screw extruder stands out as a vital component for manufacturers looking to optimize their production lines. This sophisticated piece of equipment is designed specifically to handle polyethylene terephthalate (PET) and is renowned for its versatility and efficiency in processing a wide range of plastic materials. One of the primary advanta

2025/11

From Raw Material to Product: The Crucial Role of PET Single Screw Extruders in Manufacturing

From Raw Material to Product: The Crucial Role of PET Single Screw Extruders in Manufacturing Table of Contents 1. Introduction to PET and Its Importance in Manufacturing 2. Understanding the Extrusion Process 3. What is PET? A Deep Dive into Polyethylene Terephthalate 4. Single Screw Extruders: The Heart of PET Processing 5. Advantages of Using Single Screw Extruders for PET

RELATED INFORMATION

Why Choose Conical Twin Screw for Your Next Extrusion Project?

Why Choose Conical Twin Screw for Your Next Extrusion Project? Understanding Extrusion Technology In the realm of **plastic processing**, extrusion is an essential manufacturing technique that transforms raw plastic materials into usable products. The **extrusion process** involves forcing molten plastic through a die to create continuous shapes like sheets, films, and profiles. With advancements

Understanding the Advantages of Counter Rotating Twin Screw Extruders for Plastic Processing

Counter rotating twin screw extruders are pivotal in the plastic processing industry, recognized for their versatility and efficiency. Unlike single screw extruders, twin screw extruders feature two intermeshing screws that rotate in opposite directions. This design allows for enhanced material handling and processing capabilities, making them suitable for a wide array of applications. One of the