2025/11

Understanding the Benefits and Applications of Counter Rotating Twin Screw Extruders

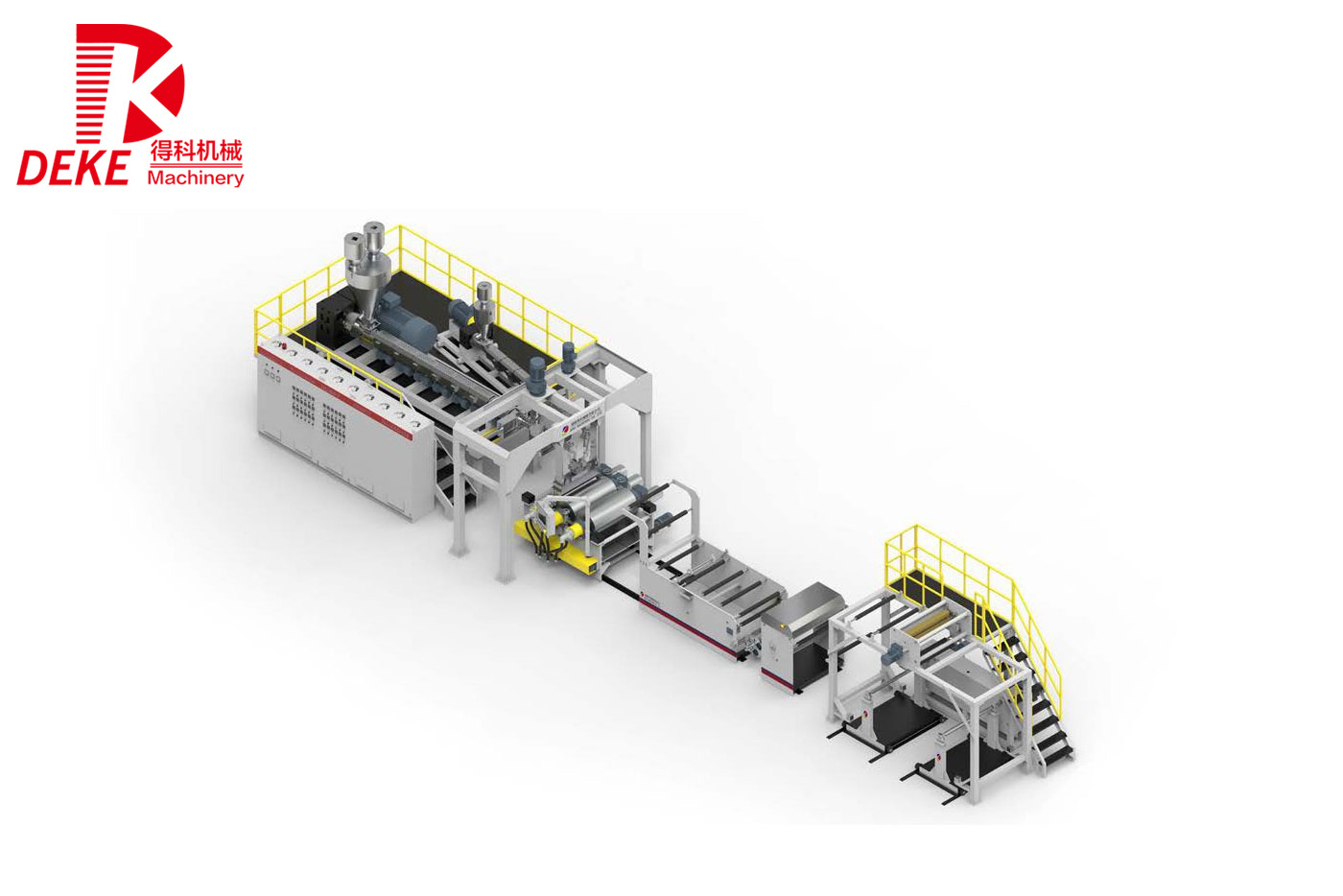

Counter rotating twin screw extruders are a vital component in the realm of plastic processing machinery, known for their unique design and operational advantages. Unlike traditional single screw extruders, the counter rotating twin screw extruder consists of two screws that rotate in opposite directions. This configuration allows for enhanced mixing, compounding, and transport of materials, makin

2025/11

The Science Behind Twin Screw Extruder Performance in Plastic Processing

The Science Behind Twin Screw Extruder Performance in Plastic Processing In the realm of plastic processing, twin screw extruders play a pivotal role in the manufacturing of a wide variety of plastic products. Their intricate design and operational mechanics make them indispensable in achieving high-performance plastic processing. This article will delve deep into the science behind twin screw ext

2025/11

The Versatility and Efficiency of Twin Screw Compounders in Plastic Processing

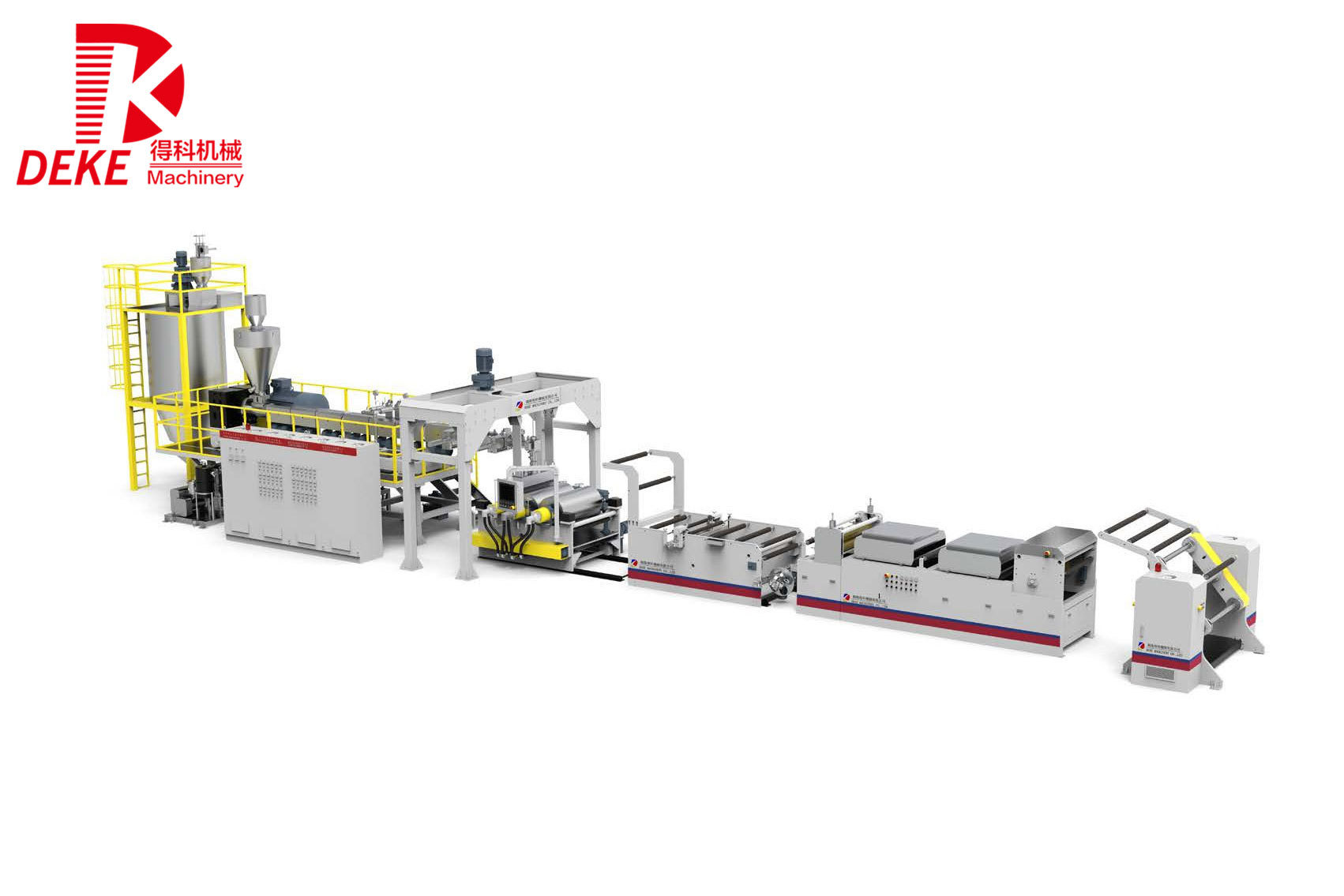

Twin screw compounders are advanced machinery extensively used in the plastic processing industry, particularly in the manufacturing of various plastic products. These machines utilize two intermeshing screws that rotate in the same direction to efficiently blend, melt, and homogenize materials. One of the primary advantages of twin screw compounders is their ability to handle a wide range of mate

2025/11

How a PET Sheet Extruder Machine Significantly Enhances Production Efficiency

How a PET Sheet Extruder Machine Significantly Enhances Production Efficiency Table of Contents Introduction to PET Sheet Extruder Machines Understanding PET Sheets and Their Applications The Mechanism of PET Sheet Extrusion Key Benefits of Using PET Sheet Extruder Machines Enhanced Production Efficiency Cost-Effectiveness Quality Impro

2025/11

Understanding the PET Sheet Extruder: Key Features and Benefits

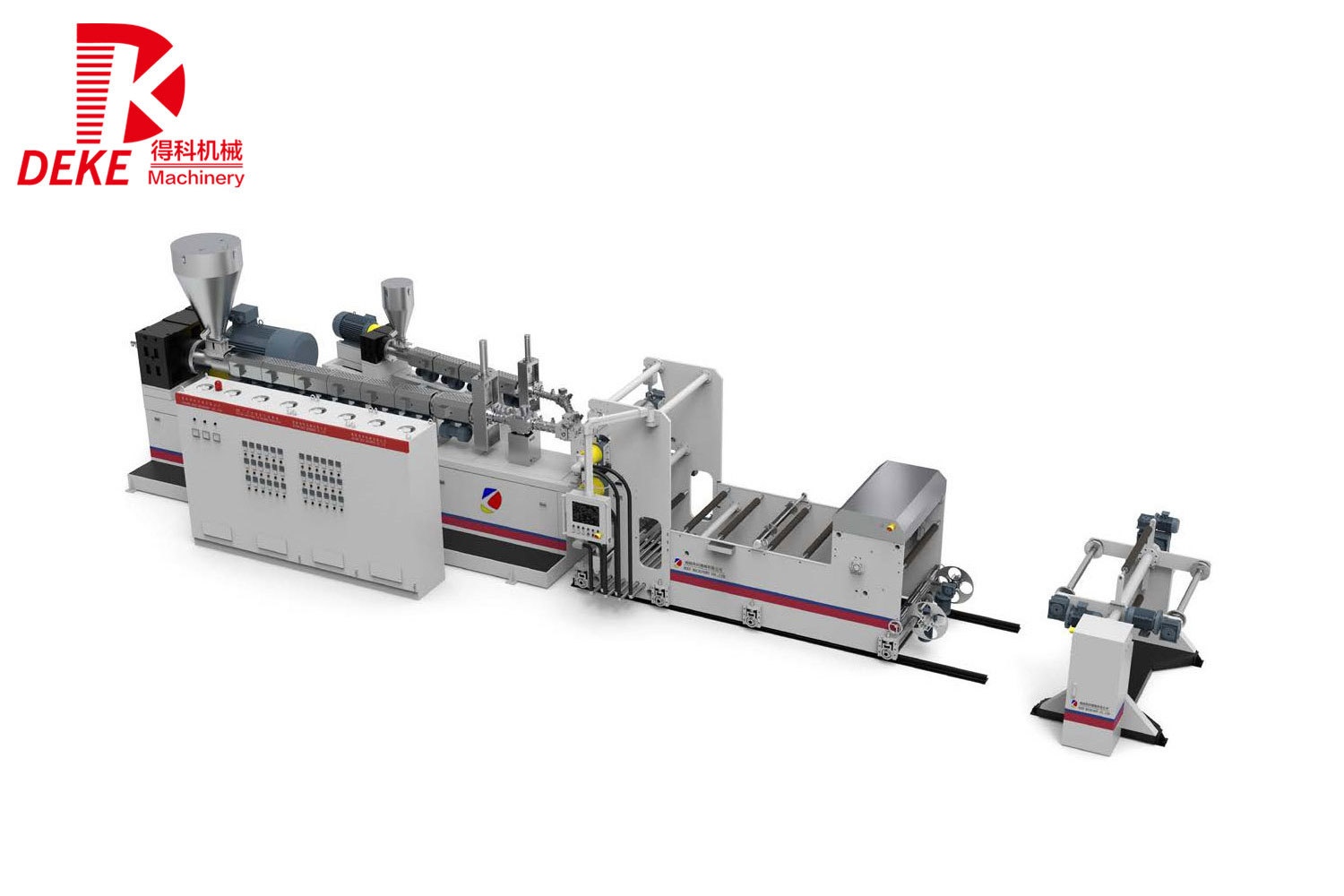

The PET sheet extruder is a vital piece of equipment in the plastic processing machinery sector, particularly for the production of polyethylene terephthalate (PET) sheets. PET is renowned for its excellent clarity, strength, and recyclability, making it a preferred choice in various applications such as packaging, automotive, and construction. Understanding the functionality and benefits of a PET

2025/11

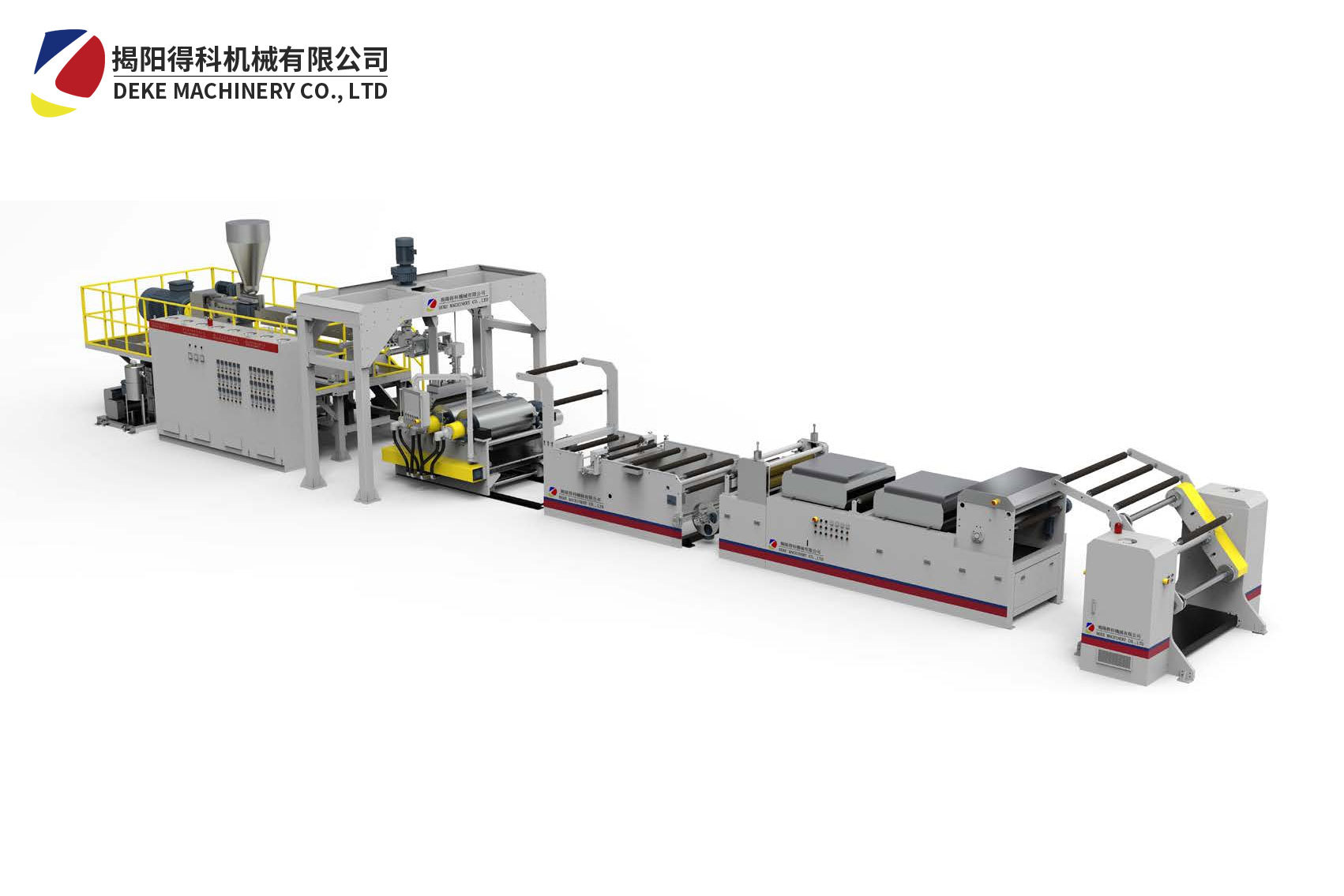

How PET Twin Screw Extruders Can Revolutionize Your Production Line

How PET Twin Screw Extruders Can Revolutionize Your Production Line Table of Contents Introduction to PET Twin Screw Extruders Understanding the Technology Behind Twin Screw Extruders Advantages of PET Twin Screw Extruders Key Applications of PET Twin Screw Extruders Energy Efficiency and Sustainability in Production Choosing the Right PET Twin Screw Extruder for Your Need

2025/11

Understanding Counter Rotating Twin Screw Extruders: A Comprehensive Guide

Counter rotating twin screw extruders are advanced machines widely used in the plastic processing industry. These extruders are engineered to enhance the mixing, compounding, and extrusion of various plastic materials. The unique feature of counter rotating twin screw extruders lies in their two screws that rotate in opposite directions, providing several benefits over traditional single screw and

2025/11

How to Optimize Your Compounding Process with Twin Screw Extruders

How to Optimize Your Compounding Process with Twin Screw Extruders Introduction to Twin Screw Extruders in Plastic Processing In the realm of plastic manufacturing, twin screw extruders play a pivotal role in the compounding process. These machines not only melt and mix polymers but also facilitate the incorporation of various additives, fillers, and colorants, offering flexibility and efficiency.

2025/11

Understanding Twin Screw Compounders: Key Insights for Plastic Processing Professionals

Twin screw compounders are essential equipment in the plastic processing industry, renowned for their versatility and efficiency in compounding and extruding various polymer materials. Designed with two intermeshing screws, these machines provide a unique advantage: they facilitate a high degree of mixing and kneading, making them ideal for producing a wide range of plastic compounds. One of the p

2025/11

An In-Depth Look at the Technical Specifications of PET Sheet Extruder Machines

An In-Depth Look at the Technical Specifications of PET Sheet Extruder Machines Table of Contents Introduction to PET Sheet Extruder Machines Understanding PET: Properties and Applications The Extrusion Process: A Step-by-Step Guide Key Technical Specifications of PET Sheet Extruder Machines Performance Metrics: What to Look For Energy Efficiency and Sustainability Conside

RELATED INFORMATION

Why Choose Conical Twin Screw for Your Next Extrusion Project?

Why Choose Conical Twin Screw for Your Next Extrusion Project? Understanding Extrusion Technology In the realm of **plastic processing**, extrusion is an essential manufacturing technique that transforms raw plastic materials into usable products. The **extrusion process** involves forcing molten plastic through a die to create continuous shapes like sheets, films, and profiles. With advancements

Understanding the Advantages of Counter Rotating Twin Screw Extruders for Plastic Processing

Counter rotating twin screw extruders are pivotal in the plastic processing industry, recognized for their versatility and efficiency. Unlike single screw extruders, twin screw extruders feature two intermeshing screws that rotate in opposite directions. This design allows for enhanced material handling and processing capabilities, making them suitable for a wide array of applications. One of the